Specific Process Knowledge/Lithography/Resist

Feedback to this page: click here

UV Resist

UV resist comparison table

Comparison of specifications and feature space of the standard UV photoresists available at DTU Nanolab.

| Resist | AZ 5214E | AZ MiR 701 | AZ nLOF 2020 | AZ 4562 | SU-8 | TI Spray |

|---|---|---|---|---|---|---|

| Resist tone |

|

Positive | Negative | Positive | Negative |

|

| Thickness range | 1.5 - 4.2 µm | 1.5 - 4 µm | 1.5 - 4 µm | 5 - 10 µm | 1 - 200 µm | 0.5 - 5 µm |

| Coating tool |

Automatic spin coaters:

Manual spin coaters:

Spray coater |

Automatic spin coaters:

Manual spin coaters:

Spray coater |

Automatic spin coaters:

Manual spin coaters:

Spray coater |

Automatic spin coaters:

Manual spin coaters:

|

Manual spin coaters:

|

Spray coater |

| Spectral sensitivity | 310 - 420 nm | 310 - 445 nm | 310 - 380 nm | 310 - 445 nm | 300 - 375 nm | 310 - 440 nm |

| Exposure tool |

|

|

|

|

|

|

| Developer |

|

|

|

AZ 726 MIF (2.38% TMAH) |

mr-DEV 600 (PGMEA) |

AZ 726 MIF (2.38% TMAH) |

| Development rinse agent | DIW | DIW | DIW | DIW | IPA | DIW |

| Remover |

|

|

|

Remover 1165 (NMP) |

|

|

| Comments | Good adhesion for wet etch | High selectivity for dry etch | Negative sidewalls for lift-off | For processes with resist thickness between 6 µm and 25 µm |

|

TI spray resist is an image reversal resist, similar to AZ 5214E. The process flow will be similar to the process flows for 5214, except for the coating step. The exposure dose and development will depend on the specific process. |

Process flow examples

Comparison of specifications and feature space of the standard UV photoresists available at DTU Nanolab. These are just examples and may contain obsolete information regarding exposure dose, etc.

| Resist | AZ 5214E | AZ MIR 701 | AZ nLOF 2020 | AZ 4562 | SU-8 | Ti Spray |

|---|---|---|---|---|---|---|

| Maskless aligner |

NB! Most of the process knowledge about SU-8 is based in research groups |

|||||

| Mask aligner |

NB! Most of the process knowledge about SU-8 is based in research groups |

Other process flows: Chip on carrier: A procedure for UV lithography on a chip using automatic coater and developer.

Exposure dose

During exposure of the resist, the photoinitiator, or photo-active component, reacts with the exposure light, and starts the reaction which makes the resist develop in the developer.

In a positive resist, it makes the resist become soluble in the developer. In a negative resist, usually assisted by thermal energy in the post-exposure bake (PEB), it makes the resist insoluble in the developer. The amount of light required to fully develop the resist in the development process, is the exposure dose.

The optimal exposure dose is a function of many parameters, including the type of resist, the resist thickness, and the sensitivity of the resist.

Resist sensitivity

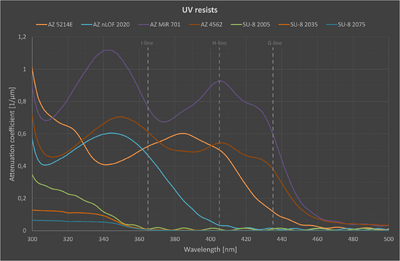

The resist sensitivity is a measure of how efficiently it reacts to the exposure light. Spectral sensitivity is the sensitivity of the resist as a function of wavelength. It is usually given simply as the range from the wavelength below which absorption in the resist material makes lithography impractical to the wavelength at which the photoinitiator is no longer efficiently activated.

Within the sensitivity range, the optical absorption is commonly used as a measure of sensitivity. A high absorption coefficient signifies a high sensitivity, as the light is absorbed by the photoinitiator. Because of spectral sensitivity, the optimal dose of a given resist type and thickness is also a function of the spectral distribution of the exposure light, i.e. the equipment used for the exposure. Using a combination of experience, calculation and assumptions, it may be possible to estimate the dose for an exposure equipment, if the exposure dose is already known on another equipment.

Due to reflection and refraction at the interface between the resist and the substrate, the optimal dose may also be a function of the type of substrate used. Unless otherwise stated, the exposure doses given below are for standard silicon wafers.

Apart from the already mentioned factors, the optimal dose also depends on the developer chemistry and the parameters used in the development process. Finally, the requirements to the lithographic process in terms of resolution, bias (line broadening), etch selectivity, side wall angle, etc. may narrow down, or widen, the process window. The exposure doses given in the sections below should be used as a starting point for individual fabrication process development.

Due to the process of bleaching, where the absorption of the resist changes during exposure, the exposure dose is unfortunately not always constant at different intensities of the exposure light. The exposure time is thus not always a linear function of the exposure intensity.

Calculate exposure time

In the maskless aligners, the dose is set directly as a process parameter in the job. In mask aligners, on the other hand, the parameter that is set is the exposure time, i.e. how long the shutter is open during the exposure.

The exposure dose, D [J/m2], in terms if exposure light intensity I [W/m2] and exposure time t [s], is given by:

Since the intensity is specific to the spectral sensitivity of the sensor used to measure the exposure light, and the exposure time is specific to the spectral distribution of the exposure light (cf. spectral sensitivity), this dose is specific to the combination of exposure source and optical sensor.

Given an exposure dose, the exposure time, t, is calculated as:

It is important to keep in mind that this exposure time is valid only for a specific combination of exposure source and optical sensor, as well as for a specific development process.

Exposure dose for mask aligners

Information about the exposure dose for mask aligners can be found here.

Exposure dose for maskless aligners

Information about the exposure dose for maskless aligners can be found here.

Exposure dose when using AZ 351B developer (NaOH)

Information about the exposure dose when using AZ 351B developer can be found here.

DUV Resist

DUV resist overview

The spinning process will be performed by the customer together with the Photolith group of Nanolab. In case you would like to do DUV lithography, please contact Lithography team, who will consult you and run your wafers together with you.

Bottom Anti Reflection Coating (BARC):

Positive DUV resist for spin coating in 600-300nm thickness range:

Positive DUV resist for spin coating in 1600-800nm thickness range:

Negative DUV resist for spin coating in 1400-800nm or diluted with EC Solvent in 1:1 in 400-200nm thickness range:

- Manufacturers website: UVN2300-0.8

- Datasheet: UVN2300-0.8 - requires login

E-beam Resist

Standard E-beam resists and process guidelines

DTU Nanolab offers a limited number of standard EBL resist for our users. Our standard resist and process guidelines are summarized below. CSAR (AR-P 6200.09) is installed on Spin coater Gamma E-beam & UV for spin coating of 2", 4" and 6" substrates. Other substrate sizes or resist have to be used in the Labspin 2/3 coating systems. The standard resist bottles are stored in the chemical cupboard in E-4.

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spin Coater | Thinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| CSAR AR-P 6200 | Positive | AllResist | Standard positive resist, very similar to ZEP520. | AR-P 6200 info | Gamma E-beam & UV or Labspin 2/3 | Anisole |

|

IPA |

|

Process Flow CSAR with Al Process Flow LOR5A with CSAR |

| Medusa AR-N 8200 | Negative | AllResist | Both e-beam and DUV sensitive resist. | AR-N 8200 info | Labspin 2/3 | AR 600-07 | AR 300-47:DIW (1:1) | DIW | BOE | |

| AR-N 7500 | Negative | AllResist | Both e-beam, DUV and UV-sensitive resist. | AR-N 7500 info | Labspin 2/3 | PGMEA |

|

DIW |

|

Non-Standard E-beam resists

It is possible to obtain permission to user other resists at DTU Nanolab, users must however provide these resists and possibly developers themselves. A non-exhaustive list of user supplied EBL resist used at DTU Nanolab and some process guidelines can be found in the table below.

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spin Coater | Thinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| ZEP520A | Positive resist, contact Lithography if you plan to use this resist | ZEON | Positive resist | ZEP520A.pdf, ZEP520A spin curves on SSE Spinner | See table here | Anisole | ZED-N50/Hexyl Acetate,n-amyl acetate, oxylene. JJAP-51-06FC05.pdf, JVB001037.pdf | IPA | acetone/1165 | Process_Flow_ZEP.docx

|

| Copolymer AR-P 617 | Positive | AllResist | Approved, not tested yet. Used for trilayer (PE-free) resist-stack or double-layer lift-off resist stack. Please contact Lithography for information. | AR_P617.pdf | See table here | PGME | AR 600-55, MIBK:IPA | acetone/1165 | Trilayer stack: Process_Flow_Trilayer_Ebeam_Resist.docx | |

| mr EBL 6000.1 | Negative | MicroResist | Standard negative resist | mrEBL6000 processing Guidelines.pdf | See table here | Anisole | mr DEV | IPA | mr REM | Process_Flow_mrEBL6000.docx |

| HSQ (XR-1541) | Negative | DOW Corning | Approved. Standard negative resist | HSQ Dow Corning, MSDS HSQ | See table here | TMAH, AZ400K:H2O | H2O | process flow HSQ | ||

| AR-N 7520 | Negative | AllResist | Both e-beam, DUV and UV-sensitive resist. Currently being tested, contact Peixiong Shi for information. | AR-N7500-7520.pdf | See table here | PGMEA | AR 300-47, TMAH | H2O | ||

| PMMA | Positive | AllResist | We have various types of PMMA in the cleanroom. Please contact Lithography for information. | See table here | Anisole | MIBK:IPA (1:3), IPA:H2O | IPA | acetone/1165/Pirahna |

| |

| ZEP7000 | Positive | ZEON | Not approved. Low dose to clear, can be used for trilayer (PEC-free) resist-stack. Please contact Lithography for information. | ZEP7000.pdf | See table here | Anisole | ZED-500/Hexyl Acetate,n-amyl acetate, oxylene. | IPA | acetone/1165 | Trilayer stack: Process_Flow_Trilayer_Ebeam_Resist.docx |

Imprint Resist

Imprint Resist Overview

Here is a table with 2 different imprint resists we have recently used in the cleanroom, with links to a purchase manufactor, technical reports about resist properties and a current process flow, tested in our cleanroom.

| Resist | Manufacturer | Comments | Technical reports | Thinner | Spinner | Rinse | Process flows (in docx-format) |

| Topas | micro resist technology | Users may purchase own resist. | Topas.pdf | LabSpin03 or LabSpin03 | IPA | ||

| mr-I 7030R | micro resist technology | We purchase only mr-I 7030R, to use it please contact Lithography. | mr-I 7030R.pdf | mr-T 1050 | LabSpin03 or LabSpin03 | Acetone | Preparation substrate with mr-I 7030R: Preparation substrate with imprint layer |