Specific Process Knowledge/Lithography/UVLithography

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

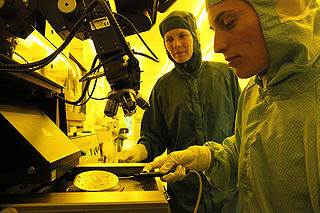

UV Lithography uses ultraviolet light to transfer a pattern from a photo-mask or a design file to a wafer coated with photoresist. The photoresist film is spin coated onto the wafers, the design is transferred to the resist by using an aligner, and subsequently the resist pattern is developed. DTU Nanolab houses a number of automatic or manual coaters, mask or maskless aligners, as well as automatic or semi-automatic developers.

Getting started

Before you plan your UV processing and request for training on any equipment in UV lithography, please go through the following steps. Include the information in the training request.

Also, please remember that the Lithography TPT is mandatory before training in any lithography equipment.

If you are new to photolithography, you can visit this wikipedia webpage about photolithography before you start.

Pre-cleanroom work:

- Complete the Lithography TPT.

- Prepare a process flow: The process flow describes all steps in your UV lithography process. You can find docx-templates in this table.

- Design device: Design your device and layout. A detailed instruction on how to design a layout (or mask) can be found here.

- Mask: If you wish to use a mask aligner, order a photomask for your UV process. Instructions on how to order a photomask can be found here.

Cleanroom work:

- Substrate pretreatment: In many processes it is recommended to pretreat or prime your wafer before spin-coating. In some spin-coaters, these pretreatment processes are included in the spin coating of resist.

- Resist Type: Choose the type of resist you wish to use: a list of UV lithography resist types available at DTU Nanolab can be found on this page.

- Positive tone resist: Resist exposed to UV light will be dissolved in the developer. For mask aligners, the mask openings are an exact copy of the resist pattern which is to remain on the wafer.

- Negative tone resist: Resist exposed to UV light will become polymerized and difficult to dissolve. For mask aligners, the mask openings are an inverse copy of the resist pattern which is to remain on the wafer.

- Thickness of resist: In general, it is recommended to work at, or below, an aspect ratio of ~1, i.e. where the feature sizes of the pattern, is larger than the thickness of the resist. Furthermore, when you decide on the resist thickness, consider which transfer you need:

- For lift-off processes, we recommend resist thickness at least 5 times larger than the thickness of the metal to be lifted.

- For dry etch or wet etch processes, investigate the resist etch rate of your process, as this might limit the minimum thickness of your resist.

- Spin Coater: Do you wish to use a manual spin coater or an automatic spin coater? See a list of spin coaters here.

- Exposure: Choose which aligner you wish to use, and consider the exposure dose.

- Development: Choose which equipment you wish to use to develop your photoresist from this list. Remember the development process influences the exposure dose.

- Specify whether you wish to strip or lift-off your resist: strip and lift-off.

Process information

UV Resist

Pretreatment

Coating

Baking

UV Exposure Tools

Development

Descum

Lift-off

Stripping Resist

Information from our suppliers

Application notes from MicroChemicals GmbH, e.g. Lithography Trouble-Shooter