Specific Process Knowledge/Lithography/UVLithography

Appearance

Feedback to this page: click here

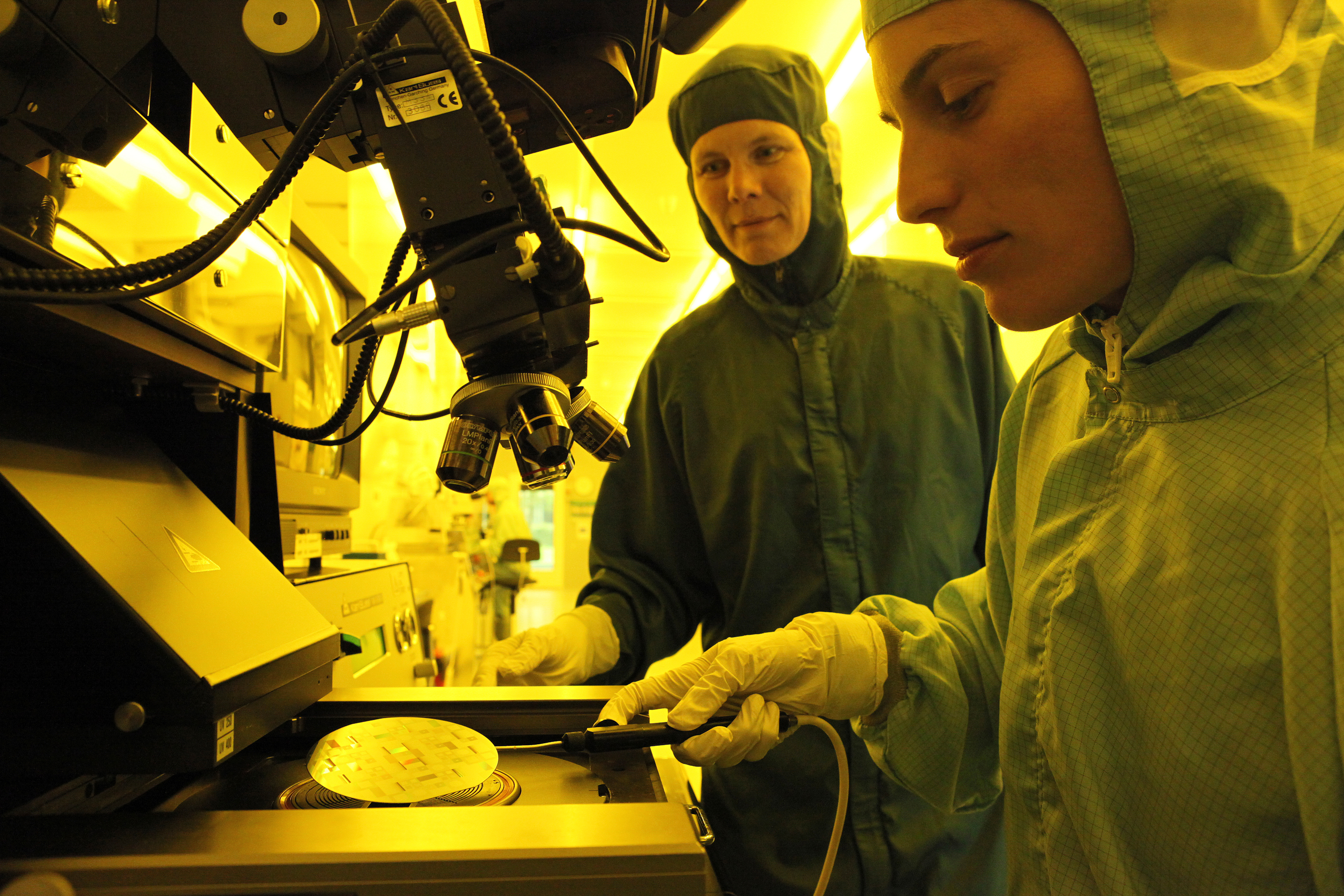

UV Lithography uses ultraviolet light to transfer a pattern from a mask to a wafer coated with photoresist. The photoresist film is spin coated on the wafers and the pattern is transferred to the wafer by using a mask aligner. DTU Danchip houses a number of automatic or semi-automatic coaters and mask aligners.

Getting started

Before you plan your UV processing and request for training on any equipment in UV lithography, please go through the following steps.

If you are new to photolithography, you can visit this wikipedia webpage about photolithography before you start.

- Prepare a process flow which describes all steps in your UV lithography process. You can find docx-templates in this table.

- Substrate pretreatment: In many processes it is recommended to pretreat or prime your wafer before spin-coating. In some spin-coaters, these pretreatment processes are included in the spin coating of resist.

- Spin Coater: Do you wish to use a manual spin coater or a robot spin coater? A manual spin coater is recommended for batches < 5 wafers. See a list of spin coaters here.

- Resist Type: Choose the type of resist you wish to use: a list of UV lithography resist types available at DTU Danchip can be found on this page.

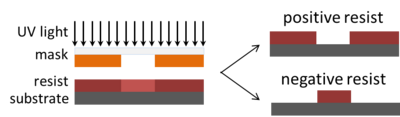

- Positive tone resist: Resist exposed to UV light will be dissolved in the developer. The mask is an exact copy of the pattern which is to remain on the wafer.

- Negative tone resist: Resist exposed to UV light will become polymerized and difficult to dissolve. The mask is an inverse copy of the pattern which is to remain on the wafer.

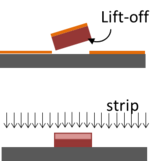

- Thickness of resist: In general, it is recommended to work at or below an aspect ratio of ~1, i.e. where the width of the pattern is not smaller than the thickness of the resist. Furthermore, when you decide for the resist thickness, consider which transfer you need:

- For lift-off processes, we recommend resist thicknnesses ~5 times larger than the thickness of the metal to be lifted.

- For dry or wet etch processes, investigate the resist etch rate of your process as this might limit the minimum thickness of your resist.

- Exposure: Choose which mask aligner you wish to use; you can find a list of mask aligners here.

- Mask: Design and order a photomask for your UV process. A detailed instruction on how to design and order a photomask can be found here.

- Development: Choose which equipment you wish to use to develop your photoresist from this list.

Resist Overview

| Resist | Polarity | Spectral sensitivity | Manufacturer | Comments | Technical reports | Spin Coating | Exposure | Developer | Rinse | Remover | Process flows (in docx-format) |

| AZ 5214E | Positive but the image can be reversed | 310 - 420 nm | AZ Electronic Materials | Can be used for both positive and reverse processes with resist thickness between 1 and 4 µm. | AZ5214E.pdf | SSE,

KS Spinner or |

KS Aligner, | AZ 351B developer

or |

DI water | Acetone | |

| AZ 4562 | Positive | 310 - 440 nm | AZ Electronic Materials | For process with resist thickness between 6 and 25 µm. | AZ4500.pdf | SSE or | KS Aligner, | AZ 351B developer

or |

DI water | Acetone | Process_Flow_thick_AZ4562.docx |

| AZ MiR 701 | Positive | 310 - 445 nm | AZ Electronic Materials | High selectivity for dry etch.

Resist thickness 1 - 2 µm. |

AZ_MiR_701.pdf | Spin Track 1 + 2 | KS Aligner, | AZ 726 MIF developer | DI water | Remover 1165 | Process_Flow_AZ_MiR701.docx |

| AZ nLOF 2020 | Negative | 310 - 380 nm | AZ Electronic Materials | Negative sidewalls for lift-off.

Resist thickness 1.5 - 3 µm. |

AZ_nLOF_2020.pdf | Spin Track 1 + 2 | KS Aligner, | AZ 726 MIF developer | DI water | Remover 1165 | Process_Flow_AZ_nLOF_2020.docx |

| SU-8 | Negative | 350 - 400 nm | Microchem | High aspect ratio.

Resist thickness 1 µm to several 100 µm. |

SU-8_DataSheet_2005.pdf, SU-8_DataSheet_2075.pdf | KS Spinner | Aligner-6inch,

KS Aligner or |

mr-Dev 600 developer (PGMEA) | IPA | Plasma ashing can remove crosslinked SU-8 | Process_Flow_SU8_70um.docx |