LabAdviser: Difference between revisions

| Line 382: | Line 382: | ||

!Entry page in LabAdviser | !Entry page in LabAdviser | ||

!Topic | !Topic | ||

|- | |||

|[[LabAdviser/Introduction_to_LabAdviser_and_Processing|Introduction to LabAdviser and Processing]] | |||

|Solar cell flow | |||

|- | |- | ||

|[[Process_flow_approval|Process flow approval]] | |[[Process_flow_approval|Process flow approval]] | ||

|Info on process flow review | |Info on process flow review | ||

|- | |- | ||

|[[Specific Process Knowledge/Lithography/UVLithography#Resist Overview|UV Lithography#Resist Overview]] | |[[Specific Process Knowledge/Lithography/UVLithography#Resist Overview|UV Lithography#Resist Overview]] | ||

Revision as of 13:50, 7 May 2021

LabAdviser is a wiki accessible for users of the DTU Nanolab facilities. If you are not a current user, please take a look at our homepage. You can also take a virtual tour of the DTU Nanolab cleanroom facility or explore our YouTube channel with a selection of training videos.

LabAdviser contains information about

- equipment at DTU Nanolab that covers micro and nano fabrication in the cleanroom facility in building 346 and surroundings (in building 346 and 347) and characterization equipment, primarily electron microscopy, at building 314 and 307.

- fabrication steps in micro and nano fabrication that takes place at the cleanroom fabrication facility and surroundings and

- electron microscopy methods that takes place at building 314/307.

An overview of the equipment in these facilities can be found and some fabrication process flows and singles fabrication steps are described. In general LabAdviser is meant to advise you to the right equipment and to advise you to a good starting point for your micro and nano fabrication steps as for your electron microscopy work. This should not be replacing communication with the staff of the facilities but we recommend it as a good starting point before contacting the staff. To enter LabAdviser you need to log in with your DTU login. LabAdviser is only editable for the staff of the facilities. If you need further information about certain machinery or processes, please contact the relevant staff. Any feedback or input you might have to LabAdviser is welcome and can be given by mail to the LabAdviser mailbox: labadviser@nanolab.dtu.dk

News in LabAdviser:

- The latest LabAdviser update: LabAdviser update send out 2020-10-02

- Slides from the latest Tech Forum from September 15, 2020 are here: Tech_Forum_2020_2

Contents

- Introduction to LabAdviser and Micro/Nano Fabrication

- Introduction to LabManager

- Process flow approval (fabrication)

- Characterization in building 314/307

- Micro and Nano Fabrication Overview

- DTU Nanolab Projects - Technology Research

- Courses (Introduction course, Tool Package Training's (TPT))

- Surveys, statistics, monthly LabAdviser updates and other info.

- How to add information to LabAdviser

Overview of micro and nano fabrication steps - a guide to where you can find fabrication information in LabAdviser:

|

||||||||||||||

Contact Information for the DTU Nanolab fabrication part

DTU Nanolab Fabrication Cleanroom Naming and Phone Numbers

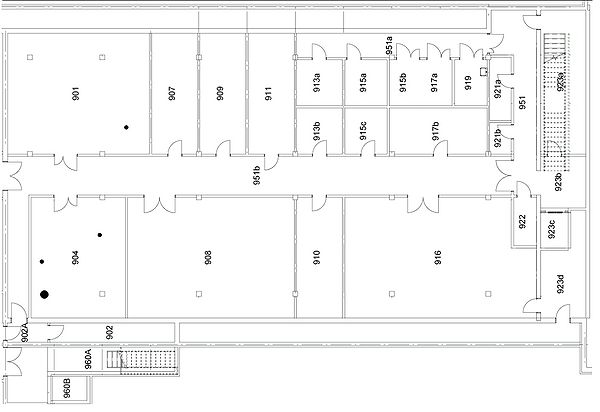

Cleanroom builing 346 ground floor

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||

Basement builing 346 phase 1

DTU Nanolab building 314 and Phone Numbers

|

|

|

||||||||||||||||||||||||||||||||||||||||