Specific Process Knowledge/Lithography/UVLithography: Difference between revisions

Appearance

| Line 20: | Line 20: | ||

|'''Technical reports''' | |'''Technical reports''' | ||

|'''[[Specific_Process_Knowledge/Lithography/Coaters|Spin Coating]]''' | |'''[[Specific_Process_Knowledge/Lithography/Coaters|Spin Coating]]''' | ||

|'''[[Specific_Process_Knowledge/Lithography/Development| | |'''[[Specific_Process_Knowledge/Lithography/Development|Developer]]''' | ||

|'''Rinse''' | |'''Rinse''' | ||

|'''Remover''' | |'''Remover''' | ||

| Line 31: | Line 31: | ||

|'''AZ5214E''' | |'''AZ5214E''' | ||

|Positive | |Positive | ||

| | |AZ Electronic Materials | ||

| | |Can be used for both positive and reverse processes with resist thickness between 1 to 4um. | ||

|[[media:AZ5214E.pdf|AZ5214E.pdf]] | |[[media:AZ5214E.pdf|AZ5214E.pdf]] | ||

|[[Specific_Process_Knowledge/Lithography/Coaters#SSE Spinner|SSE]], [[Specific_Process_Knowledge/Lithography/Coaters#KS Spinner|KS Spinner]], [[Specific_Process_Knowledge/Lithography/Coaters#III-V Spinner|III-V Spinner]] | |[[Specific_Process_Knowledge/Lithography/Coaters#SSE Spinner|SSE]], [[Specific_Process_Knowledge/Lithography/Coaters#KS Spinner|KS Spinner]], [[Specific_Process_Knowledge/Lithography/Coaters#III-V Spinner|III-V Spinner]] | ||

| | |351B developer | ||

| | |DI water | ||

| | |Acetone | ||

| | | | ||

| Line 45: | Line 45: | ||

|'''AZ4562''' | |'''AZ4562''' | ||

|Positive | |Positive | ||

| | |AZ Electronic Materials | ||

| | |For process with resist thickness between 6 and 25um. | ||

|[[media:AZ4500.pdf|AZ4500.pdf]] | |[[media:AZ4500.pdf|AZ4500.pdf]] | ||

|[[Specific_Process_Knowledge/Lithography/Coaters#SSE Spinner|SSE]], [[Specific_Process_Knowledge/Lithography/Coaters#KS Spinner|KS Spinner]] | |[[Specific_Process_Knowledge/Lithography/Coaters#SSE Spinner|SSE]], [[Specific_Process_Knowledge/Lithography/Coaters#KS Spinner|KS Spinner]] | ||

| | |351B developer | ||

| | |DI water | ||

| | |Acetone | ||

| | | | ||

| Line 58: | Line 58: | ||

|'''AZ MiR 701''' | |'''AZ MiR 701''' | ||

|Positive | |Positive | ||

| | |AZ Electronic Materials | ||

| | |High selectivity for dry etch. | ||

|[[media:AZ_MiR_701.pdf|AZ_MiR_701.pdf]] | |[[media:AZ_MiR_701.pdf|AZ_MiR_701.pdf]] | ||

|[[Specific_Process_Knowledge/Lithography/Coaters#Spin Track 1 + 2|Spin Track 1 + 2]] | |[[Specific_Process_Knowledge/Lithography/Coaters#Spin Track 1 + 2|Spin Track 1 + 2]] | ||

| | |AZ 726 MIF developer | ||

| | |DI water | ||

| | |Remover 1165 | ||

|[[media:Process_Flow_AZ_MiR701.docx|Process_Flow_AZ_MiR701.docx]] | |[[media:Process_Flow_AZ_MiR701.docx|Process_Flow_AZ_MiR701.docx]] | ||

| Line 71: | Line 71: | ||

|'''AZ nLOF 2020''' | |'''AZ nLOF 2020''' | ||

|Negative | |Negative | ||

| | |AZ Electronic Materials | ||

| | | | ||

|[[media:AZ_nLOF_2020.pdf|AZ_nLOF_2020.pdf]] | |[[media:AZ_nLOF_2020.pdf|AZ_nLOF_2020.pdf]] | ||

|[[Specific_Process_Knowledge/Lithography/Coaters#Spin Track 1 + 2|Spin Track 1 + 2]] | |[[Specific_Process_Knowledge/Lithography/Coaters#Spin Track 1 + 2|Spin Track 1 + 2]] | ||

| | |AZ 726 MIF developer | ||

| | |DI water | ||

| | |Remover 1165 | ||

|[[media:Process_Flow_AZ_nLOF_2020.docx|Process_Flow_AZ_nLOF_2020.docx]] | |[[media:Process_Flow_AZ_nLOF_2020.docx|Process_Flow_AZ_nLOF_2020.docx]] | ||

Revision as of 11:53, 13 September 2013

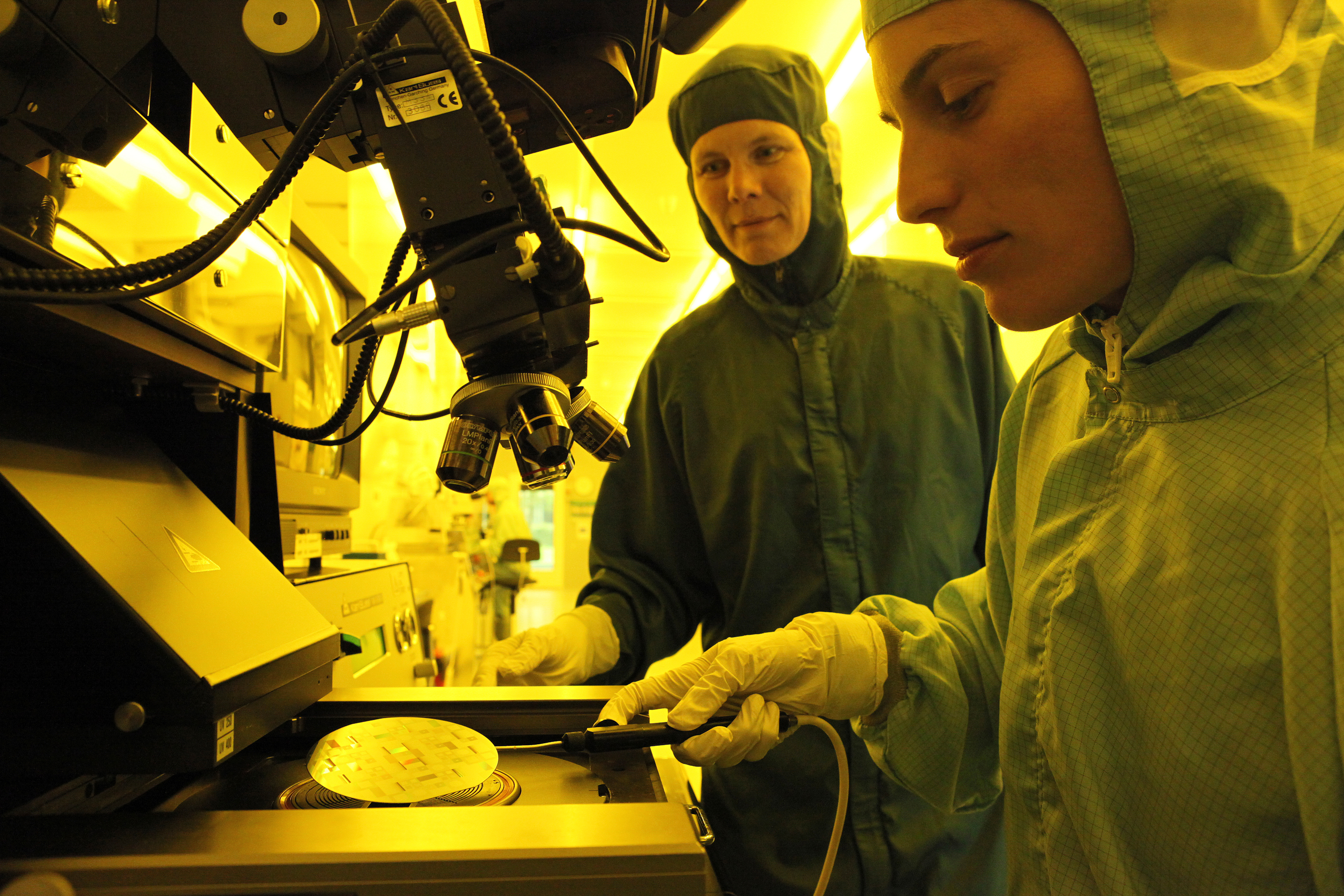

UV Lithography uses ultraviolet light to transfer a pattern from a mask to a wafer coated with photoresist. The photoresist film is spin coated on the wafers and the pattern is transferred to the wafer by using a mask aligner. DTU Danchip houses a number of automatic or semi-automatic coaters and mask aligners.

Resist Overview

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spin Coating | Developer | Rinse | Remover | Process flows (in docx-format) |

| AZ5214E | Positive | AZ Electronic Materials | Can be used for both positive and reverse processes with resist thickness between 1 to 4um. | AZ5214E.pdf | SSE, KS Spinner, III-V Spinner | 351B developer | DI water | Acetone |

|

| AZ4562 | Positive | AZ Electronic Materials | For process with resist thickness between 6 and 25um. | AZ4500.pdf | SSE, KS Spinner | 351B developer | DI water | Acetone | |

| AZ MiR 701 | Positive | AZ Electronic Materials | High selectivity for dry etch. | AZ_MiR_701.pdf | Spin Track 1 + 2 | AZ 726 MIF developer | DI water | Remover 1165 | Process_Flow_AZ_MiR701.docx |

| AZ nLOF 2020 | Negative | AZ Electronic Materials | AZ_nLOF_2020.pdf | Spin Track 1 + 2 | AZ 726 MIF developer | DI water | Remover 1165 | Process_Flow_AZ_nLOF_2020.docx

| |

| SU8 | Negative | KS Spinner |

|