Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using Plasma Asher

Appearance

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

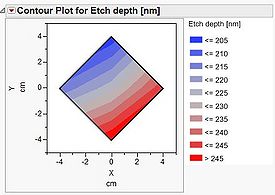

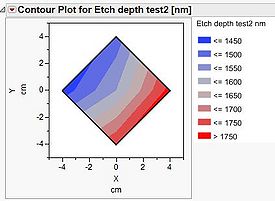

SiO2 can be etched in the Plasma Asher using CF4

Test work done January 2014 by Lis Nielsen and Berit Herstrøm @Nanolab

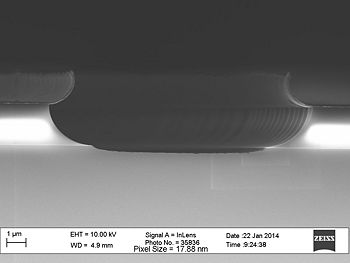

SiO2 can be etched in the Plasma Asher using CF4 and aluminum as a masking material. This gives an isotropic etch. In test2 the SiO2 layer has been etched through and there is a small over etch in the Silicon substrate. The masking material is 100 nm Al. Etch rate and uniformity measurements have been done on wafers with no mask.

- Images of isotropic SiO2 etch in the Plasma asher: Test 2

-

Profile image - a little rotated

-

Profile image

-

Tilted profile image of lines

-

Tilted profile image of lines