Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using Plasma Asher

Jump to navigation

Jump to search

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

SiO2 can be etched in the Plasma Asher using CF4

Test work done January 2014 by Lis Nielsen and Berit Herstrøm @Nanolab

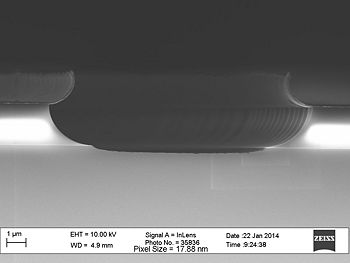

SiO2 can be etched in the Plasma Asher using CF4 and aluminum as a masking material. This gives an isotropic etch. In test2 the SiO2 layer has been etched through and there is a small over etch in the Silicon substrate. The masking material is 100 nm Al. Etch rate and uniformity measurements have been done on wafers with no mask.

- Images of isotropic SiO2 etch in the Plasma asher: Test 2

| Plasma Asher parameter settings and results for the tests | ||||||

| Test1 | Test2 | |||||

|---|---|---|---|---|---|---|

| O2 flow | 0 sccm | 0 sccm | ||||

| N2 flow | 0 sccm | 0 sccm | ||||

| CF4 flow | 200 sccm | 200 sccm | ||||

| Power | 1000 W | 1000 W | ||||

| Process Time | 10 min | 50 min | ||||

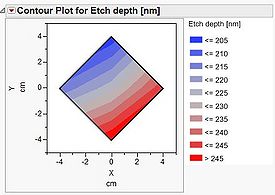

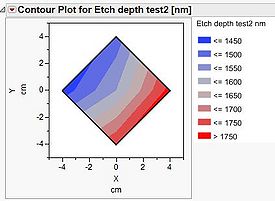

| Average Etch rate on wafer (5 points measured) | 22.6 nm/min | 31.8 nm/min | ||||

| Non-uniformity over the wafer (5 points measured) | ±10.8 % | ±11.0 % | ||||

| Non-uniformity plot | ||||||