Specific Process Knowledge/Thin film deposition/Furnace LPCVD PolySilicon/Boron doped poly-Si

Results from the acceptance test 2012

Results from Tempress test January 2023

In January 2023 Tempress optimized the process for boron doped polysilicon again (they wanted to make some process development for a potential customer).

The depositions were done with 25 wafers in the furnace. Only 6" wafers were used.

The process parameters and the injector design that Tempress came up with will replace the old "DOPEPOLY" recipe from the acceptance test.

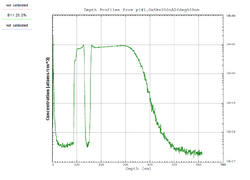

The results in table below are from run number 10.

| Recipe name | Temperature [C] (zone 1, 2, 3, 4, 5) | Gas flows [sccm] | Pressure [mTorr] | Deposition rate [nm/min] | Deposition rate - Uniformity over one wafer | Deposition rate - Uniformity over boat | Sheet resistance [Ohms/square] | Sheet resistance - Uniformity over one wafer | Sheet resistance - Uniformity over the boat |

|---|---|---|---|---|---|---|---|---|---|

| "POLYBOR" | 600, 596, 597, 600, 600 | SiH4 (through injector): 50

BCl3 (through injector): 2 |

150 | ~ 4.15 (6" wafers) | 2.9 % (door side)

1.3 % (pump side) |

0.5 % | 9.4 (door side)

10.01 (pump side) |

1.6 % (door side)

2.0 % (pump side) |

3.6 % |

Important notes about deposition of boron doped polysilicon

BCl3 (boron trichloride) gas is used for the boron doping. This is introduced into the furnace through an injector together with SiH4 (silane) gas.

The injector is a long, thin quartz tube with eight 0.7 mm wide holes, and this is needed to be able to distribute a very small flow of 2 BCl3 over the wafers in the furnace.

A new injector design to invented for the process. This design is called "8010000256 injector trial 1 0.7mm x8holes". The injector should be mounted with holes pointing towards "10 o'clock", and it can be done without cooling down the furnace - but absolute only a service technician.

An injector can only be used for a limits number of depositions, because it will be covered with polysilicon, and this has another stress level than the quartz. When about 10 um of polysilicon has been deposited on the injector, it might break. The actually happened during the testing - The injector exploded and left a very high number of quartz and polysilicon pieces on inside the cantilever.

Furthermore, the injector should only be mounted in the furnace, when boron doped polysilicon is being deposited, otherwise the holes in the injector will be blocked. For deposition of undoped polysilicon and amorphous silicon, only SiH4 gas in being used, and this in introduced directly into the furnace at the door, not through the injector.