Specific Process Knowledge/Lithography/Coaters/Spin Coater: RCD8 processing: Difference between revisions

| (40 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@ | {{:Specific Process Knowledge/Lithography/authors_generic}} | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php?title=Specific_Process_Knowledge/Lithography/Coaters/Spin_Coater:_RCD8_processing click here]''' | |||

[[Category: Equipment|Lithography]] | |||

[[Category: Lithography]] | |||

__TOC__ | |||

=Spin coating= | =Spin coating= | ||

Spin coating on Spin Coater: RCD8 consists of a selection of the following steps: | |||

#Resist dispense | |||

#(Recipe start) | |||

#Optional: Closing the Gyrset (if used) | |||

#Optional: Resist spreading at low spin speed | |||

#Spin-off | |||

#Deceleration | |||

#Opening Gyrset (if used) | |||

The wafer is first centered on the chuck and held in place by vacuum (or pins in the case of the non-vacuum chuck). After the resist has been dispensed, the recipe is started. A short spin at low spin speed may be used as the first step of the recipe, in order to spread the resist over the wafer surface before spin-off. | |||

The spin-off cycle determines the thickness of the resist coating. The thickness is primarily a function of the spin-off speed and the spin-off time, both following an inverse power-law. | |||

The acceleration to the spin-off speed also influences the thickness, but the effect is dependent on previous steps. The spin-off is usually a simple spin at one speed, but it may be comprised of several steps at different spin speeds. After spin-off, the wafer is decelerated. | |||

=Dispense= | |||

Resist dispense on the Spin Coater: RCD8 can only be done manually, as the motorized media arm was decommissioned in 2024. Manual dispense is done by administering the resist directly onto the substrate, after it has been loaded into the machine but before the recipe has been started. In most cases, it is done by pushing the resist out of a prefilled syringe (dispense cartridge). Thin resists can be dispensed by pouring the resist directly from a bottle, but that is more difficult to control. | |||

The | The volume dispensed from a syringe may be estimated by measuring the distance the resist level is displaced during a dispense, and calculating the corresponding volume using the diameter of the syringe (23 mm). A displacement of 10 mm corresponds to a dispensed volume of 4 ml. This calculation can also be used to mark the syringe with appropriately spaced guide lines in order to dispense a specific volume. 4-5 ml is an appropriate volume for a 100 mm wafer. | ||

= | ==Tips and tricks for dispensing thick resist== | ||

High viscosity resists, such as the SU-8 formulations for coating thicknesses 50µm and above, are difficult to dispense. To have any kind of control, they require use of a dispense syringe. | |||

Automatic dispense on the Spin Coater: RCD8 is done using a Nordson EFD Performus VII pressurised cartridge dispense system. The syringe containing the resist is mounted on the media arm, and the resist is dispensed using a nitrogen pressure supplied by the control box. The dispense rate is controlled by the nitrogen pressure, while the dispense time, and thus the volume, is set in the recipe. The dispensed volume may be estimated by measuring the distance the resist level is displaced during a dispense, and calculating the corresponding volume using the diameter of the syringe (23 mm). | '''Filling the syringe:'''<br> | ||

Syringes should be filled the day before spin coating, especially for thick resists like SU-8 3035 or XFT 75. They should be stored vertical in order to allow bubbles to settle at the top. | |||

A syringe consists of an end cap, the syringe barrel, and a piston that seals off the syringe after filling. To fill a syringe, bring all the necessary parts to a fume hood, along with the resist bottle. It is recommended to clean all parts with a nitrogen gun (these parts are standard labware and therefore not supplied particle-free). Put the end cap on the syringe barrel and open the resist bottle. Hold the syringe at a slight angle and slowly start pouring the resist from the bottle. Start gently and be patient; the flow of resist can quickly become too fast and too wide for the syringe. Allow the resist to flow down along the inner wall of the syringe to minimize bubble formation, taking care to avoid the top few cm of the syringe. You'll need some free space at the top for the piston; so, please stop pouring the resist before it's too late, as the viscous resist will continue to flow once you have lowered the bottle. If the resist drips on the outside of the bottle, wipe it off, but avoid wiping the opening of the bottle (due to risk of contaminating the remaining resist). When you have put down the resist bottle, insert the piston and push it all the way down to the surface of the resist in the syringe. Wipe any resist from the end of the syringe. Finally, label your syringe and store it in the chemical cabinet (in E-4). | |||

'''Dispensing from the syringe:'''<br> | |||

Start by removing the end cap from the syringe. For the first dispense, remove any air in the tip of the syringe by dispensing the first drop somewhere outside the substrate. Start the dispense in the center of the wafer, keeping the tip of the syringe as close to the substrate as possible (so the dispensed resist forms a continuous puddle, rather than strings that bunch up and trap air). Make sure the dispensed resist puddle is in the center of the substrate; otherwise, some of the substrate may not be covered during spinning, even though a lot of resist was dispensed. During dispensing, the position of the puddle can be controlled by moving the syringe tip while continuing the dispensing process. Towards the end of the dispense, move the tip to the edge of the puddle. Stop the dispense, but keep the tip at the last spot to allow the last resist to finish flowing. Now, lift the tip a couple of cm up, then down again and up again, in order to break the thin string of resist that forms between the tip and the puddle. | |||

'''Bubbles in the resist film after coating:'''<br> | |||

Bubbles in the resist after coating can successfully be popped (using e.g. an Eppendorf pipette tip), either while still on the chuck or after moving to the hotplate. Sometimes bubbles appear in the film during the first stage of softbaking. These can also be popped. | |||

<!-- | |||

Text below was in the original section "Automatic dispense" TARAN 27-08-2025 | |||

Automatic dispense on the Spin Coater: RCD8 is done using a Nordson EFD Performus VII pressurised cartridge dispense system. The syringe containing the resist is mounted on the media arm, and the resist is dispensed using a nitrogen pressure supplied by the control box. The dispense rate is controlled by the nitrogen pressure, while the dispense time, and thus the volume, is set in the recipe. The dispensed volume may be estimated by measuring the distance the resist level is displaced during a dispense, and calculating the corresponding volume using the diameter of the syringe (23 mm). A displacement of 10 mm corresponds to a dispensed volume of 4 mL. | |||

Observed dispense rates (uncertainty from measurements ~0.1 ml/s): | Observed dispense rates (uncertainty from measurements ~0.1 ml/s): | ||

| Line 26: | Line 54: | ||

**0.5 ml/s @ 2.0 bar | **0.5 ml/s @ 2.0 bar | ||

**0.7 ml/s @ 3.0 bar | **0.7 ml/s @ 3.0 bar | ||

*'''SU-8 2035:''' | |||

**0.5 ml/s @ 1.0 bar | |||

*'''SU-8 2010:''' | *'''SU-8 2010:''' | ||

**1.1 ml/s @ 0.1 bar | **1.1 ml/s @ 0.1 bar | ||

*'''KMPR 1025:''' | |||

**0.4 ml/s @ 0.5 bar | |||

**0.7 ml/s @ 1.0 bar | |||

*'''AZ 5214E:''' | *'''AZ 5214E:''' | ||

**1.2 ml/s @ 0.1 bar | **1.2 ml/s @ 0.1 bar | ||

**2.4 ml/s @ 0.18 bar | **2.4 ml/s @ 0.18 bar | ||

= | ==Edge bead removal== | ||

== | The automatic dispense system may also be used to administer solvent at the edge of the wafer after spin coating in order to remove the edge bead. Edge bead removal, or EBR, is usually done using PGMEA. Due to the low viscosity of the solvent, and the relatively high pressure of the EFD control box, it is necessary to use at tip at the end of the syringe. The flow rate of the solvent is a function of the pressure and the size of the tip orifice. While the dispense rate scales roughly linearly with the pressure, it is an exponential function of the tip orifice. | ||

Observed dispense rates of PGMEA (uncertainty from measurements ~0.1 ml/s) for different tip sizes: | |||

*'''Red (0.010"):''' | |||

**0.2 ml/s @ 0.1 bar | |||

**0.25 ml/s @ 0.2 bar | |||

*'''Purple (0.020"):''' | |||

**0.3 ml/s @ 0.1 bar | |||

**0.65 ml/s @ 0.2 bar | |||

*'''Pink (0.024"):''' | |||

**0.5? ml/s @ 0.1 bar (not verified) | |||

*'''Grey (0.047"):''' | |||

**~2.5 ml/s @ 0.1 bar | |||

--> | |||

=Recipes= | |||

Auxiliary recipes, and template recipes. For each case a list of the steps/parameters in the respective recipe. | |||

Process recipes developed by Nanolab are listed under Process results. | |||

==Auxiliary recipes== | |||

*'''1 DCH Centering test''' | *'''1 DCH Centering test''' | ||

5s @ 100rpm; 5s @ 250rpm; 5s @ 500rpm. | 5s @ 100rpm; 5s @ 250rpm; 5s @ 500rpm. | ||

| Line 40: | Line 93: | ||

*'''1 DCH Gyrset cleaning''' | *'''1 DCH Gyrset cleaning''' | ||

Gyrset down; 10s @ 100rpm; 1s @ 0rpm; 10s @ -30rpm; 20s @ 1500rpm; Gyrset up. | Gyrset down; 10s @ 100rpm; 1s @ 0rpm; 10s @ -30rpm; 20s @ 1500rpm; Gyrset up. | ||

<!-- | |||

*'''1 DCH predispense''' | *'''1 DCH predispense''' | ||

0.2s dispense at cup (arm position 0mm). | 0.2s dispense at cup (arm position 0mm). | ||

--> | |||

==SU-8 | ==Manual dispense templates== | ||

*'''1 TMPLT man disp''' | |||

Spin-off; deceleration. | |||

*'''1 TMPLT man disp spread''' | |||

Spread step; spin-off; deceleration. | |||

*'''1 TMPLT man disp Gyrset''' | |||

Gyrset down; spin-off; deceleration; Gyrset up. | |||

*'''1 TMPLT man disp Gyrset sprd''' | |||

Gyrset down; spread step; spin-off; deceleration; Gyrset up. | |||

<!-- | |||

==Automatic dispense templates== | |||

*'''1 TMPLT aut disp SU8''' | |||

Dispense; SU-8 string breaking; spread step; spin-off; deceleration. | |||

*'''1 TMPLT aut disp SU8 Gyrset''' | |||

Dispense; SU-8 string breaking; Gyrset down; spread step; spin-off; deceleration; Gyrset up. | |||

*'''1 TMPLT aut disp''' | |||

Dispense; spin-off; deceleration. | |||

*'''1 TMPLT aut disp spread''' | |||

Dispense; spread step; spin-off; deceleration. | |||

*'''1 TMPLT aut disp Gyrset''' | |||

Dispense; Gyrset down; spin-off; deceleration; Gyrset up. | |||

*'''1 TMPLT aut disp Gyrset sprd''' | |||

Dispense; Gyrset down; spread step; spin-off; deceleration; Gyrset up. | |||

--> | |||

=Processing results= | |||

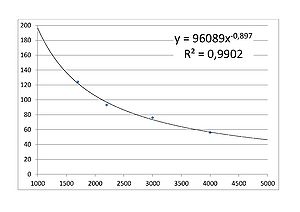

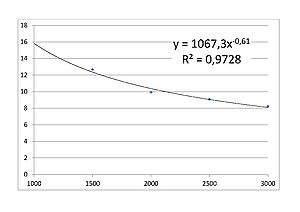

==SU-8 2075== | ==SU-8 2075== | ||

[[Image:RCD8 SU-8 2075.jpg|300x300px|thumb|right|Spin curve for SU-8 2075]] | [[Image:RCD8 SU-8 2075.jpg|300x300px|thumb|right|Spin curve for SU-8 2075]] | ||

[[Image:RCD8 SU-8 2075 Gyrset.jpg|300x300px|thumb|right|Spin curve for SU-8 2075 using Gyrset]] | [[Image:RCD8 SU-8 2075 Gyrset.jpg|300x300px|thumb|right|Spin curve for SU-8 2075 using Gyrset]] | ||

Spin coating of SU-8 2075 on Spin Coater: RCD8 using automatic dispense consists of three process steps: static dispense, spread, and spin-off. In the static dispense step the | Spin coating of SU-8 2075 on Spin Coater: RCD8 using automatic dispense consists of three process steps: static dispense, spread, and spin-off. In the static dispense step the media arm is moved to the center of the wafer, and resist is dispensed for 7s, yielding a volume of 3.5ml at 2.0 bar. After the dispense, the media arm is moved up and down in a series of steps designed to break the string of resist between the syringe and the wafer. In the spread step the wafer is accelerated to 700rpm at 50rpm/s, and spun for 25s. In the spin-off step the wafer is accelerated at 500rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s. | ||

<br>In the Gyrset version, the Gyrset is closed after the dispense step, and opened after the spin-off step. | <br>In the Gyrset version, the Gyrset is closed after the dispense step, and opened after the spin-off step. | ||

| Line 163: | Line 243: | ||

''Recipe names, process parameters, and test results:'' | ''Recipe names, process parameters, and test results:'' | ||

*'''1 DCH MiR 701 man disp 2um''' | *'''1 DCH MiR 701 man disp 2um''' <sup>1)</sup> | ||

Spin-off: 30 s at 2350 rpm. | Spin-off: 30 s at 2350 rpm. | ||

| Line 185: | Line 265: | ||

|} | |} | ||

<sup>1)</sup> Not implemented yet. | |||

<br clear="all" /> | <br clear="all" /> | ||

| Line 192: | Line 273: | ||

''Recipe names, process parameters, and test results:'' | ''Recipe names, process parameters, and test results:'' | ||

*'''1 DCH nLOF 2020 man disp 2.3um''' | *'''1 DCH nLOF 2020 man disp 2.3um''' <sup>1)</sup> | ||

Spin-off: 30 s at 2500 rpm. | Spin-off: 30 s at 2500 rpm. | ||

| Line 214: | Line 295: | ||

|} | |} | ||

<sup>1)</sup> Not implemented yet. | |||

<br clear="all" /> | <br clear="all" /> | ||

Latest revision as of 10:15, 3 November 2025

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Spin coating

Spin coating on Spin Coater: RCD8 consists of a selection of the following steps:

- Resist dispense

- (Recipe start)

- Optional: Closing the Gyrset (if used)

- Optional: Resist spreading at low spin speed

- Spin-off

- Deceleration

- Opening Gyrset (if used)

The wafer is first centered on the chuck and held in place by vacuum (or pins in the case of the non-vacuum chuck). After the resist has been dispensed, the recipe is started. A short spin at low spin speed may be used as the first step of the recipe, in order to spread the resist over the wafer surface before spin-off.

The spin-off cycle determines the thickness of the resist coating. The thickness is primarily a function of the spin-off speed and the spin-off time, both following an inverse power-law. The acceleration to the spin-off speed also influences the thickness, but the effect is dependent on previous steps. The spin-off is usually a simple spin at one speed, but it may be comprised of several steps at different spin speeds. After spin-off, the wafer is decelerated.

Dispense

Resist dispense on the Spin Coater: RCD8 can only be done manually, as the motorized media arm was decommissioned in 2024. Manual dispense is done by administering the resist directly onto the substrate, after it has been loaded into the machine but before the recipe has been started. In most cases, it is done by pushing the resist out of a prefilled syringe (dispense cartridge). Thin resists can be dispensed by pouring the resist directly from a bottle, but that is more difficult to control.

The volume dispensed from a syringe may be estimated by measuring the distance the resist level is displaced during a dispense, and calculating the corresponding volume using the diameter of the syringe (23 mm). A displacement of 10 mm corresponds to a dispensed volume of 4 ml. This calculation can also be used to mark the syringe with appropriately spaced guide lines in order to dispense a specific volume. 4-5 ml is an appropriate volume for a 100 mm wafer.

Tips and tricks for dispensing thick resist

High viscosity resists, such as the SU-8 formulations for coating thicknesses 50µm and above, are difficult to dispense. To have any kind of control, they require use of a dispense syringe.

Filling the syringe:

Syringes should be filled the day before spin coating, especially for thick resists like SU-8 3035 or XFT 75. They should be stored vertical in order to allow bubbles to settle at the top.

A syringe consists of an end cap, the syringe barrel, and a piston that seals off the syringe after filling. To fill a syringe, bring all the necessary parts to a fume hood, along with the resist bottle. It is recommended to clean all parts with a nitrogen gun (these parts are standard labware and therefore not supplied particle-free). Put the end cap on the syringe barrel and open the resist bottle. Hold the syringe at a slight angle and slowly start pouring the resist from the bottle. Start gently and be patient; the flow of resist can quickly become too fast and too wide for the syringe. Allow the resist to flow down along the inner wall of the syringe to minimize bubble formation, taking care to avoid the top few cm of the syringe. You'll need some free space at the top for the piston; so, please stop pouring the resist before it's too late, as the viscous resist will continue to flow once you have lowered the bottle. If the resist drips on the outside of the bottle, wipe it off, but avoid wiping the opening of the bottle (due to risk of contaminating the remaining resist). When you have put down the resist bottle, insert the piston and push it all the way down to the surface of the resist in the syringe. Wipe any resist from the end of the syringe. Finally, label your syringe and store it in the chemical cabinet (in E-4).

Dispensing from the syringe:

Start by removing the end cap from the syringe. For the first dispense, remove any air in the tip of the syringe by dispensing the first drop somewhere outside the substrate. Start the dispense in the center of the wafer, keeping the tip of the syringe as close to the substrate as possible (so the dispensed resist forms a continuous puddle, rather than strings that bunch up and trap air). Make sure the dispensed resist puddle is in the center of the substrate; otherwise, some of the substrate may not be covered during spinning, even though a lot of resist was dispensed. During dispensing, the position of the puddle can be controlled by moving the syringe tip while continuing the dispensing process. Towards the end of the dispense, move the tip to the edge of the puddle. Stop the dispense, but keep the tip at the last spot to allow the last resist to finish flowing. Now, lift the tip a couple of cm up, then down again and up again, in order to break the thin string of resist that forms between the tip and the puddle.

Bubbles in the resist film after coating:

Bubbles in the resist after coating can successfully be popped (using e.g. an Eppendorf pipette tip), either while still on the chuck or after moving to the hotplate. Sometimes bubbles appear in the film during the first stage of softbaking. These can also be popped.

Recipes

Auxiliary recipes, and template recipes. For each case a list of the steps/parameters in the respective recipe.

Process recipes developed by Nanolab are listed under Process results.

Auxiliary recipes

- 1 DCH Centering test

5s @ 100rpm; 5s @ 250rpm; 5s @ 500rpm.

- 1 DCH Chuck cleaning

10s @ 100rpm; 1s @ 0rpm; 10s @ -30rpm; 20s @ 1500rpm.

- 1 DCH Gyrset cleaning

Gyrset down; 10s @ 100rpm; 1s @ 0rpm; 10s @ -30rpm; 20s @ 1500rpm; Gyrset up.

Manual dispense templates

- 1 TMPLT man disp

Spin-off; deceleration.

- 1 TMPLT man disp spread

Spread step; spin-off; deceleration.

- 1 TMPLT man disp Gyrset

Gyrset down; spin-off; deceleration; Gyrset up.

- 1 TMPLT man disp Gyrset sprd

Gyrset down; spread step; spin-off; deceleration; Gyrset up.

Processing results

SU-8 2075

Spin coating of SU-8 2075 on Spin Coater: RCD8 using automatic dispense consists of three process steps: static dispense, spread, and spin-off. In the static dispense step the media arm is moved to the center of the wafer, and resist is dispensed for 7s, yielding a volume of 3.5ml at 2.0 bar. After the dispense, the media arm is moved up and down in a series of steps designed to break the string of resist between the syringe and the wafer. In the spread step the wafer is accelerated to 700rpm at 50rpm/s, and spun for 25s. In the spin-off step the wafer is accelerated at 500rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s.

In the Gyrset version, the Gyrset is closed after the dispense step, and opened after the spin-off step.

Recipe names, process parameters, and test results:

- 1 DCH SU8 aut disp 100um

Spin-off: 30 s at 2100 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 100 µm | 3.5% | 14/4 2015 | taran | 5 points on one wafer, exclusion zone 15mm |

- 1 DCH SU8 aut dsp Grst 100um

Spin-off: 30 s at 2000 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 99 µm | 3.0% | 15/4 2013 | taran | 5 points on one wafer, exclusion zone 15mm |

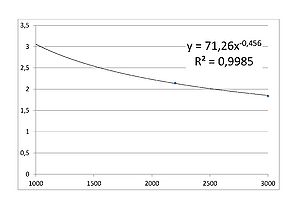

AZ 4562

Spin coating of AZ 4562 on Spin Coater: RCD8 using manual dispense is a very simple process. The wafer is accelerated at 1000rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s.

Recipe names, process parameters, and test results:

- 1 DCH 4562 man disp 10um

Spin-off: 30 s at 2000 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 9.92 µm | 2.9% | 29/4 2015 | taran | 9 points on one wafer, exclusion zone 5mm Non-vacuum chuck |

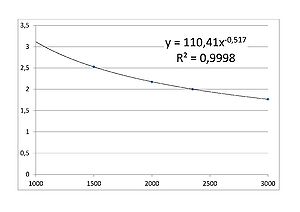

AZ 5214E

Spin coating of AZ 5214E on Spin Coater: RCD8 using manual dispense is a very simple process. The wafer is accelerated at 1000rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s.

Recipe names, process parameters, and test results:

- 1 DCH 5214E man disp 2.2um

Spin-off: 30 s at 2100 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 2.19 µm | 0.4% | 22/4 2013 | taran | 9 points on one wafer, exclusion zone 5mm |

AZ MiR 701

Spin coating of AZ MiR 701 (29cps) on Spin Coater: RCD8 using manual dispense is a very simple process. The wafer is accelerated at 1000rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s.

Recipe names, process parameters, and test results:

- 1 DCH MiR 701 man disp 2um 1)

Spin-off: 30 s at 2350 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 2.00 µm | 1.8% | 29/4 2015 | taran | 9 points on one wafer, exclusion zone 5mm Non-vacuum chuck |

1) Not implemented yet.

AZ nLOF 2020

Spin coating of AZ nLOF 2020 on Spin Coater: RCD8 using manual dispense is a very simple process. The wafer is accelerated at 1000rpm/s to the spin-off speed, spun for 30s, then decelerated at 1000rpm/s.

Recipe names, process parameters, and test results:

- 1 DCH nLOF 2020 man disp 2.3um 1)

Spin-off: 30 s at 2500 rpm.

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 2.30 µm | 1.7% | 29/4-2015 | taran | 9 points on one wafer, exclusion zone 5mm Non-vacuum chuck |

1) Not implemented yet.