Specific Process Knowledge/Lithography/Descum

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

Plasma Asher 1

Plasma asher 1 was decommissioned 2024-12-02.

Information about decommissioned tool can be found here.

Plasma Asher 2

Plasma asher 2 was decommissioned 2024-12-02.

Information about decommissioned tool can be found here.

Plasma Asher 3: Descum

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager - requires login

Plasma Asher 3 is specifically used for controlled descum process after lithography. Please note that you only can process a single 100 mm wafer, or one small sample, at a time. The plasma asher is equipped with 2 gaslines: oxygen and nitrogen, but all standard processes use only oxygen (as recommended by Diener).

Ashing of AZ MiR701 resist:

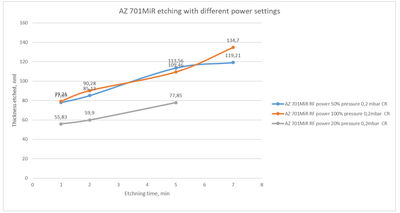

You can use two different descum process developments: you can either change power settings or processing chamber pressure.

Testing different power settings:

Recipe settings:

- O2 flow: 5 sccm

- N2 flow: 0

- Pressure: 0.2 mbar

- Power: Varied

Experiment parameters:

|

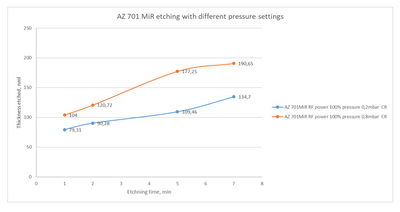

Testing different pressure settings:

Recipe settings:

- O2 flow: varied

- N2 flow: 0

- Pressure: varied

- Power: V100% (100 W)

Experiment parameters:

|

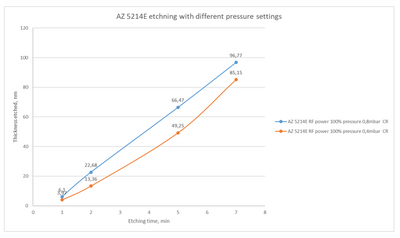

Ashing of AZ5214E resist:

Recipe settings:

- O2 flow: varied

- N2 flow: 0

- Pressure: varied

- Power: V100% (100 W)

Experiment parameters:

|

Plasma Asher 4

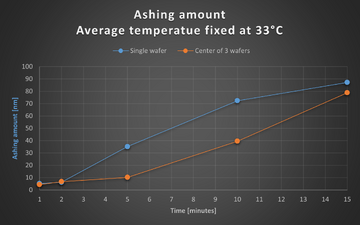

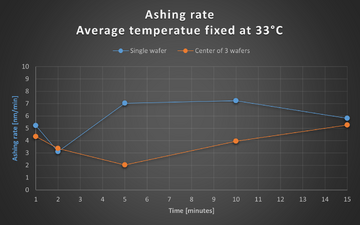

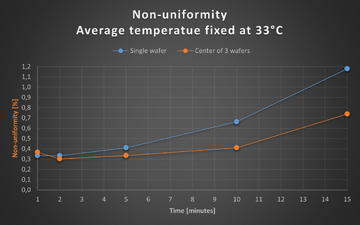

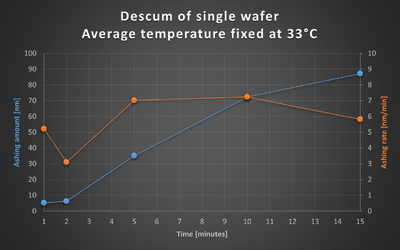

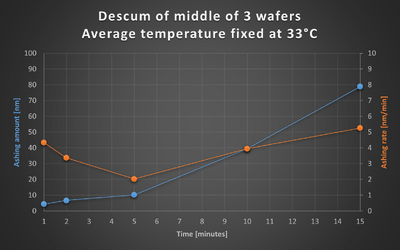

Descum of AZ 5214E on 100 mm wafers. The descum process development was done for a single substrate, as well as 3 substrates (for decreased ashing rate and improved ashing uniformity). The substrates were placed vertically in the glass boat.

For the 3 substrates only the center substrate was used for testing, the front and back wafers were used as dummy wafers. The wafers were placed in consecutive slots - when running multiple wafers in this way, the first and last wafers should always be dummy wafers.

The user manual, risk assessment, and contact information can be found in LabManager - requires login

Typical descum parameters

Tested with 1.5 µm AZ 5214E on 100 mm silicon substrate.

- O2: 100 sccm

- N2: 100 sccm

- Pressure (DSC): 1.3 mbar

- Power: 200 W

- Chamber temperature at start: 30°C

- Time (single wafer): 5-10 minutes = 35-72 nm ashed

- Time (multiple wafers): 10-15 minutes = 40-80 nm ashed

| Test setup | Single substrate | Center of 3 substrates |

|---|---|---|

| Test results | Ashing rate: 5.7 ±2.1 nm/min Non-uniformity: 0.6 ±0.4% |

Ashing rate: 3.8 ±1.6 nm/min Non-uniformity: 0.4 ±0.2% |

| Wafers | 1 | 3 |

| Wafer size | 100 mm | 100 mm |

| Boat position | Center of chamber | Center of chamber |

| Test wafer position | Center of boat | Center of boat |

| Total gas flow rate | 200 sccm | 200 sccm |

| Gas mix ratio | 50% N2 | 50% N2 |

| Chamber pressure | 1.3 mbar | 1.3 mbar |

| Power | 200 W | 200 W |

| Test processing time | Tested parameter | Tested parameter |

| Test average temperature | 33°C | 33°C |

Single wafer ashing rate an uniformity

| Ashing time [min]: | 1 | 2 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| Ashing amount [nm]: | 5.2 | 6.2 | 35.1 | 72.3 | 87.1 |

| Ashing rate [nm/min]: | 5.2 | 3.1 | 7.0 | 7.2 | 5.8 |

| Ashing time [min]: | 1 | 2 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| Pre-descum film thickness range [nm]: | 11 | 12 | 10 | 11 | 9 |

| Pre-descum non-uniformity [%]: | 0.37 | 0.40 | 0.33 | 0.37 | 0.30 |

| Post-descum film thickness range [nm]: | 10 | 10 | 12 | 19 | 33 |

| Post-descum non-uniformity [%]: | 0.33 | 0.33 | 0.41 | 0.66 | 1.18 |

Multi wafer ashing rate and uniformity

| Ashing time [min]: | 1 | 2 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| Ashing amount [nm]: | 4.3 | 6.7 | 10.1 | 39.5 | 78.8 |

| Ashing rate [nm/min]: | 4.3 | 3.4 | 2.0 | 4.0 | 5.3 |

| Ashing time [min]: | 1 | 2 | 5 | 10 | 15 |

|---|---|---|---|---|---|

| Pre-descum film thickness range [nm]: | 11 | 13 | 11 | 12 | 14 |

| Pre-descum non-uniformity [%]: | 0.37 | 0.43 | 0.37 | 0.40 | 0.46 |

| Post-descum film thickness range [nm]: | 11 | 9 | 10 | 12 | 21 |

| Post-descum non-uniformity [%]: | 0.37 | 0.30 | 0.33 | 0.41 | 0.74 |

Comparison between single substrate processing and multi substrate processing

Processing a single substrate using the standard descum settings will provide users with a relatively controllable and uniform process. Adding dummy substrates in close proximity with the process substrate will reduce the ashing rate and improve the uniformity:

-

Ashing amount

-

Ashing rate

-

Non-uniformity

Plasma Asher 5

Plasma asher 5 is identical to plasma asher 4, see descum processing for plasma asher 4 here.