LabAdviser/Technology Research/Fabrication of Hyperbolic Metamaterials using Atomic Layer Deposition/TiO2 Q plates

Procces flow description

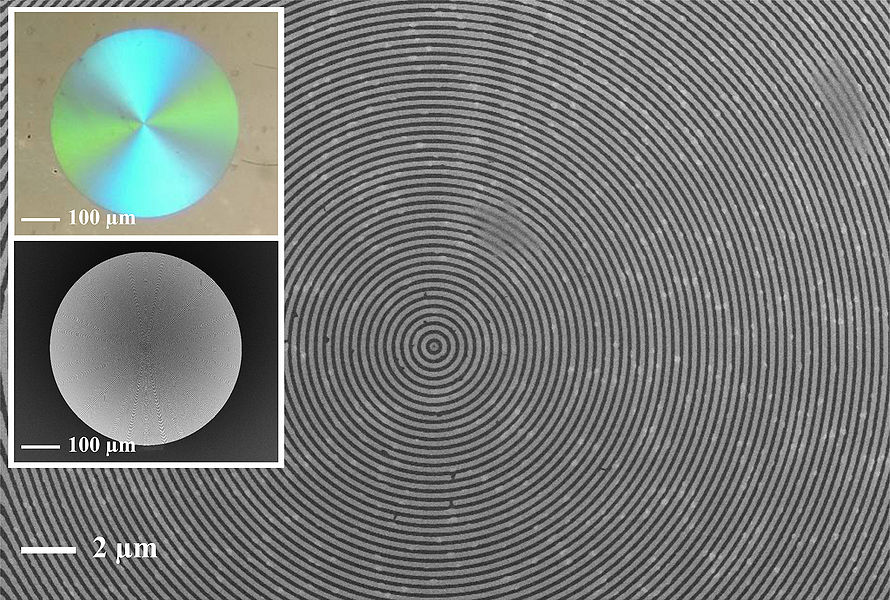

The substrates for the samples were fabricated by depositing 1 μm of Si3N4 (the resonator layer) on 100 mm silicon < 100 > wafers using low-pressure chemical vapor deposition. The process was carried out at 780C with ammonia (NH3) and dichlorosilane (SiH2Cl2) as reactive gases. Thickness and refractive index of the deposited silicon nitride was measured and confirmed using spectroscopic ellipsometry. The deposited Si3N4 film was carefully analyzed for existence of cracks, particles and other defects using dark field optical microscopy. The best-quality wafer with Si3N4 was selected and cleaved in pieces, which were used as substrates for the deposition of Al2O3/TiO2 multilayers. Before inserting each substrate into the ALD reactor, it was placed on a Si carrier wafer. Therefore the Al2O3/TiO2 multilayers were grown not only on the Si3N4 layer but also on the dummy carrier wafer. After the ALD process was completed, the dummy was cleaved and its cross-section was characterized using scanning electron microscopy (SEM). The SEM images reveal high-quality homogeneous, conformal coatings, as seen in the examples in Figs 1. Such a method of deposited multilayers characterization turned out to be more feasible than the direct SEM characterization of multilayers on Si3N4, since the latter suffers from issues related to charge accumulation on the silicon nitride.

-

High aspect ratio Al2O3 and TiO2 nanogratings.

-

High aspect ratio Al2O3 and TiO2 nanogratings.