Specific Process Knowledge/Thermal Process/BCB Curing Oven

Feedback to this page: click here

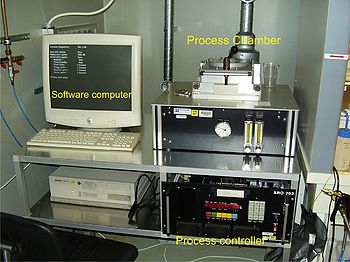

BCB Curing Oven

The BCB Curing Oven is mainly used for curing of BCB (bisbenzocyclobutene) and for alloying of metals in a nitrogen atmosphere.

During processing the furnace is rapidly heated by use of eight halogen lamps situated below the sample. The furnace is purged with a nitrogen flow (high or low flow). Samples are processed at atmospheric pressure or at vacuum.

The user manual, user APV, technical information and contact information can be found in LabManager:

Process information

Here are some of the standard processes used in the BCB Curing Oven.

BCB curing:

- Long curing at 210°C: BCB210AL.PDF/BCB210BL.PDF

- Long curing at 250°C: BCB250AL.PDF/BCB250BL.PDF

Content of BCB250BL.PDF: (the file BCB210BL.PDF is identical except that the max temperature is 210 instead of 250°C)

;

; stored 31.08.2011 at 17:55:33

{P0}

00,00:30,0020,- - - - 3 - - - -,075,250,001,005,028

01,00:10,0020,- - - 2 - - - - -

02,00:30,0020,- - - - 3 - - - -

03,00:10,0020,- - - 2 - - - - -

04,05:00,0050,H - - 2 - - - - -

05,05:00,0050,H C - 2 - - - - -

06,15:00,0100,H - 1 - - - - - -

07,45:00,0100,H C 1 - - - - - -

08,15:00,0150,H - 1 - - - - - -

09,81:00,0150,H C 1 - - - - - -

10,60:00,0250,H - 1 - - - - - -

11,60:00,0250,H C 1 - - - - - -

12,15:00,0020,- C 1 - - - - - -

13,30:00,0020,- C 1 - - - - - -

14,00:00,0010,- C - - - - - - -

The AL/BL processes are (should be) identical except for a (2x) pump/purge cycle in the beginning of the BL processes.

General processes

There are a number of general processes named DxxxCyyy.PDF.

The Dxxx is the set temperature (in °C) and the Cyyy is the time (in minutes) at the set temperature.

The oven heats to the set temperature (xxx) in 5 mins and then stays at the temperature (xxx) for a time (yyy) after which it cools to room temperature as fast as possible.

The program sequence looks like this for the file D200C060.PDF:

;

; stored 31.08.2011 at 18:15:47

{P0}

00,05:00,0200,H - - 2 - - - - -,075,250,001,005,028

01,60:00,0200,H C 1 - - - - - -

02,05:00,0002,- C 1 - - - - - -

03,00:00,0000,- C - - - - - - -

| Equipment | BCB Curing Oven | |

|---|---|---|

| Purpose |

| |

| Process parameter range | Temperature |

|

| Nitrogen flows |

| |

| Pressure |

| |

| Substrates

(Remember to use the right carrier wafer) |

Batch size |

|

| Allowed materials |

| |