Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano12: Difference between revisions

Appearance

| Line 31: | Line 31: | ||

|- | |- | ||

| Mask | | Mask | ||

| | | 343 nm zep etched down to 154 nm | ||

|- | |- | ||

|} | |} | ||

| Line 44: | Line 44: | ||

C4F8 52 sccm, SF6 38 sccm, 4 mTorr, Strike 3 secs @ 15 mTorr, 800 W CP, 50 W PP, -10 degs, 120 secs | C4F8 52 sccm, SF6 38 sccm, 4 mTorr, Strike 3 secs @ 15 mTorr, 800 W CP, 50 W PP, -10 degs, 120 secs | ||

</gallery> | </gallery> | ||

== Comments == | == Comments == | ||

Lower temperature certainly looks like a step in the right direction. Confirms that the process was too etch aggressive previously, hence the isotropic profiles. | Lower temperature certainly looks like a step in the right direction. Confirms that the process was too etch aggressive previously, hence the isotropic profiles. | ||

Revision as of 14:23, 4 May 2011

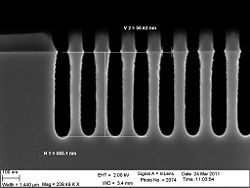

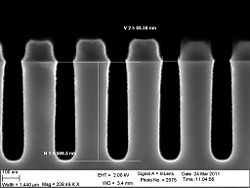

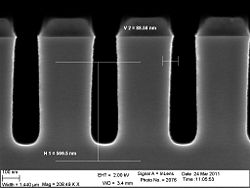

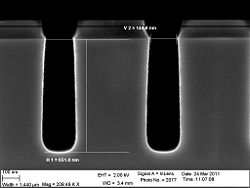

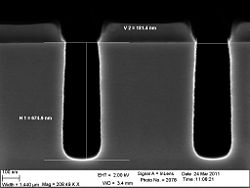

The nano1.2 recipe

| Recipe | Gas | C4F8 38 sccm, SF6 52 sccm |

|---|---|---|

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | |

| Power | 800 W CP, 50 W PP | |

| Temperature | -10 degs | |

| Hardware | 100 mm Spacers | |

| Time | 120 secs | |

| Conditions | Run ID | 1817 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

| Mask | 343 nm zep etched down to 154 nm |

- The results of the nano1.2 recipe

-

The 30 nm trenches

-

The 60 nm trenches

-

The 90 nm trenches

-

The 120 nm trenches

-

The 150 nm trenches

Comments

Lower temperature certainly looks like a step in the right direction. Confirms that the process was too etch aggressive previously, hence the isotropic profiles.