Specific Process Knowledge/Lithography/Aligners/Aligner: Maskless 02 processing: Difference between revisions

| Line 368: | Line 368: | ||

After alignment to the specified alignment marks, the Aligner: Maskless 02 will automatically compensate for the translation (shift) and rotation detected during the alignment. However, the translation is set using only the first alignment mark. This means that if there is any run-out (gain) in the wafer, the alignment will be perfect at the first alignment position, while the second alignment position will be off by the run-out error. The central part of the print will be misaligned by half the run-out error. This is different compared to alignment in a mask aligner, where the user usually splits the run-out error between the two sides, resulting in good alignment in the center. In Aligner: Maskless 02, run-out may be compensated by activating the scaling function, which only becomes available when using 3 or more alignment positions. To help assess whether the measured scaling or shearing is significant, 10 ppm (scaling = 1.000010 or 0.999990; shearing = ±0.010 mRad) corresponds to a difference of 1µm from one edge to the other on a 4" wafer. | After alignment to the specified alignment marks, the Aligner: Maskless 02 will automatically compensate for the translation (shift) and rotation detected during the alignment. However, the translation is set using only the first alignment mark. This means that if there is any run-out (gain) in the wafer, the alignment will be perfect at the first alignment position, while the second alignment position will be off by the run-out error. The central part of the print will be misaligned by half the run-out error. This is different compared to alignment in a mask aligner, where the user usually splits the run-out error between the two sides, resulting in good alignment in the center. In Aligner: Maskless 02, run-out may be compensated by activating the scaling function, which only becomes available when using 3 or more alignment positions. To help assess whether the measured scaling or shearing is significant, 10 ppm (scaling = 1.000010 or 0.999990; shearing = ±0.010 mRad) corresponds to a difference of 1µm from one edge to the other on a 4" wafer. | ||

In order to get good alignment, it is advised to use four alignment marks for alignment, and to activate scaling (possibly also shearing) before starting the exposure. Optical or pneumatic auto-focus should not affect the result, but it is recommended to use the "High Res" camera for the final alignment of each mark in order to achieve the best overlay accuracy. | In order to get good alignment, it is advised to use four alignment marks for alignment, and to activate scaling (possibly also shearing) before starting the exposure. Optical or pneumatic auto-focus should not affect the result, but it is recommended to use the "High Res" camera for the final alignment of each mark in order to achieve the best overlay accuracy. Exposure using the fast mode decreases the overlay accuracy, since the address grid size is increased to 250 nm. | ||

'''Alignment accuracy:''' | '''Alignment accuracy:''' | ||

Revision as of 09:48, 6 September 2023

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Exposure technology

Aligner: Maskless 02 is not a direct writer. In the maskless aligner, the exposure light is passed through a spatial light modulator, much like in a video projector, and projected onto the substrate, exposing a small area of the design at a time. The substrate is fully exposed by scanning the exposure field across the substrate in a succession of exposure stripes.

The light source is a laser diode (array) with a wavelength of 375 nm (2.8 W). The spatial light modulator is a digital micro-mirror device. The individual mirrors of the DMD are switched on and off in order to represent the design, and the laser is flashed on and off, in order to give the desired exposure dose. The exposure image is projected onto the substrate through a lens-system. The projected image has a pixel size of 500x500 nm on the substrate surface. The image is scanned across the substrate in stripes in order to expose the entire design. Each stripe is overlapping 2 or 5 times, depending on the chosen exposure mode), in order to reduce light-source non-uniformity effects and stitching errors. The address grid size is 250 nm or 100 nm for Fast and High Quality exposure mode, respectively.

The writing head of the Aligner: Maskless 02 moves only in the z-direction. Using the optical or pneumatic focusing system, the maskless aligner is able to do real-time dynamic autofocus. The defocus process parameter is used to offset the focusing mechanism, to optimize printing quality in different resists and resist thicknesses, as well as reflective or absorbing surfaces, and transparent or non-transparent substrates. The stage of the Aligner: Maskless 02 moves only in x and y. It has no theta-axis. All rotation during alignment is accomplished by digitally rotating the design to match the physical rotation of the substrate.

Process Parameters

The lithographic result of exposure on Aligner: Maskless 02 depends on a lot of factors, including the dose and defocus parameters, and the exposure mode used. The optimal dose and defocus depends on the type and thickness of the resist, as well as the optical properties of the substrate (e.g. reflective/absorbing/transparent). All of these factors influence the obtainable resolution, as well as the writing speed.

The correct way to determine the best dose-defocus settings is to generate a so-called Bossung plot (known from projection lithography), which plots the printed linewidth as a function of dose and defocus. From this, the most stable region of parameter space is chosen, i.e. the region where the linewidth changes the least when dose and defocus changes. Any deviation from the design linewidth may be corrected using the CD bias parameter. This typically involves SEM imaging of resist cross-sections, and quickly becomes time-consuming. However, in most cases, inspection of a dose-defocus matrix (easily generated using the series exposure function) in an optical microscope will get you most of the way.

Defocus

Aligner: Maskless 02 offers two autofocus modes; optical or pneumatic. The autofocus mode is selected via the substrate template. The defocus process parameter is used to compensate for offsets between the autofocus mechanism and the focal point of the exposure light, and simultaneously optimize print quality in different resists and varying thicknesses.

Optical:

Works for substrates down to 3x3 mm.

Pneumatic:

Substrates must be at least 5x5 mm to be successfully loaded. The pneumatic AF freezes at a distance of 3 mm form the substrate edge, which means that in order to have any dynamic focusing, using the pneumatic AF, the substrate must be larger than 6x6 mm.

Exposure mode

Aligner: Maskless 02 offers two exposure modes. The exposure mode is selected during design conversion.

High quality:

High quality mode is used for minimum stitching effects.

In the high quality mode, an area of the pattern is exposed by 5 stripes, each 500 µm wide and exposing a fifth of the dose. At the same time, sub-pixel interpolation is applied, giving an address grid size of 100 nm.

Fast:

Fast mode is used for maximum exposure speed.

In the fast mode, each area of the pattern is exposed by 2 stripes only. This effectively reduces the exposure time by 60%, but also increases the size of the address grid in the X-direction to 250 nm. Due to less averaging of non-uniformities, stitching effects will be more prominent in this mode.

Writing speed

(This section was updated 05-09-2023 by taran@nanolab)

According to specs (after being converted to write mode 2), the writing speed of Aligner: Maskless 02 is 500 mm2/min in fast mode. Using the high quality exposure mode cuts the expected speed by 2.5, to approximately 200 mm2/min. The writing speed of the machine for a 100x100 mm2 area measured after being modified to write mode 2 (2023-03-21) was ~1200 mm2/min at 100 mJ/cm2.

When the exposure is started on the maskless aligner, the software starts converting the design to the image files needed for the exposure. When sufficient data has been generated, the hardware starts exposing the sample, while more image data is being generated in the background. This simultaneous data conversion and exposure is called Online conversion. Once a design has been converted (and/or exposed) the data may be reused for repeated exposures. Due to no time lost waiting for data conversion, offline exposure may be several tens of % faster than online. However, the converted data can only be reused if no alignment is needed, including flat alignment ("Expose with substrate angle"/"Expose with Global Angle").

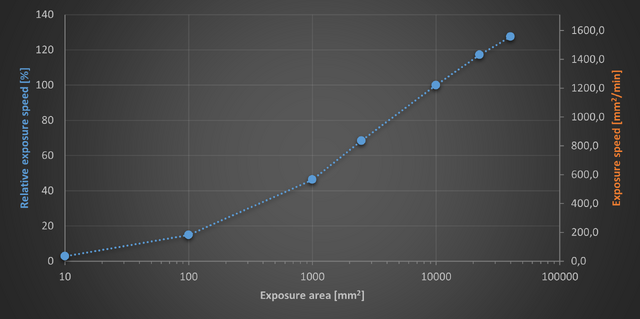

Speed vs. area:

During exposure of a stripe the stage moves at a constant speed. Each stripe thus includes a certain movement overhead for acceleration and deceleration. As the stripes get shorter, this overhead becomes more significant, and the normal writing speed is no longer achieved. For smaller samples, the writing speed of Aligner: Maskless 02 drops below the specified writing speed for a full 100 x 100 mm substrate.

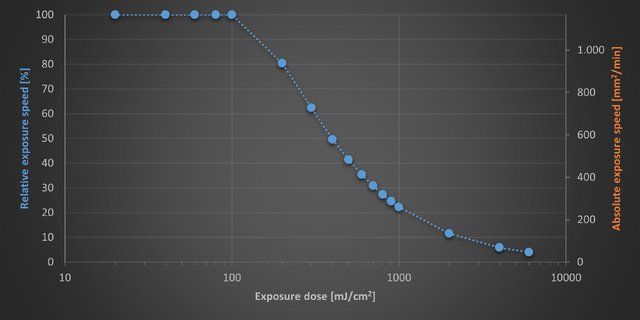

Speed vs. dose:

The writing speed is constant up to a dose of 100 mJ/cm2, then drops with increasing dose. At 500 mJ/cm2, the writing speed is approximately the nominal speed of 500 mm2/min. As a rule of thumb, the writing time doubles every time the dose is doubled.

Speed vs. design:

Depending on the complexity and density of the pattern, the conversion process may slow down the exposure significantly. A 100 mm wafer exposed with a pattern consisting of 200 million 5 µm circles took more than 16 minutes (600 mm2/min), compared to the expected 8-9 minutes (1200 mm2/min). It took 6.5 minutes before the first stripe was exposed, and there were several pauses during the print (waiting for data from conversion). Even a simple 100 x 100 mm square takes 1.5 minutes to start printing, lowering the effective writing speed to 1000 mm2/min.

The maskless aligner exposes the design in north-south oriented stripes (perpendicular to the flat). The stripes all have the same length, set by the height of the design, and only completely empty stripes are skipped. The writing speed may thus be affected by the layout of the design, as shown below.

Features

Substrate centring and flat alignment

New specs after the new writehead has been installed - section will be updated soon.

During substrate detection, the sample is scanned along the X- and Y-axes, as well as diagonally. From these measurements, the size (diameter) of the substrate is calculated, as well as the stage position matching the center of the substrate. This stage position will be the default origin for the subsequent exposure.

At the end of substrate detection, the sample is scanned twice along the bottom edge (flat), in order to determine the substrate rotation. This angle will be presented in the exposure panel along with the option to expose the design rotated in order to compensate for this angle, i.e. aligned to the flat/edge of the substrate.

Result of using "Expose with substrate angle" ("Expose with Global Angle"):

- Rotation: 0.5±0.2°

- Centring:

- X 100±250µm

- Y 200±250µm

Taran Mar 2019, average of 3 4" wafers.

The error on the flat alignment is surprising when compared to the 0±0.1° measured on Aligner: Maskless 01. The centring, on the other hand, is seen to be within a few hundred µm, without correcting for the flats.

Result of loading the same substrate ~10 times without removing it from the stage:

| Average | Range | |

|---|---|---|

| Optical autofocus

(as installed) |

3.7 mRad | ±13.9 mRad

±0.8° |

| Pneumatic autofocus

(as installed) |

-3.1 mRad | ±1.4 mRad

±0.08° |

| Positioning a wafer repeatedly using the alignment tool

(measured using pneumatic autofocus) |

-1.7 mRad | ±8.3 mRad

±0.5° |

| Optical autofocus

after hardware upgrade February 2020 |

-0.3 mRad | ±1.4 mRad

±0.08° |

| Pneumatic autofocus

after hardware upgrade February 2020 |

-0.6 mRad | ±1.4 mRad

±0.08° |

This shows that using optical autofocus (as installed) significantly increased the error on the flat measurement, while using pneumatic atuofocus performs similar to Aligner: Maskless 01. Initially, it was thus recommended to use pneumatic autofocus (or rely only on the alignment tool) for the first print if crystal alignment is important for subsequent processing. However, after the autofocus hardware and software upgrade in February 2020, the two methods yield equally good results.

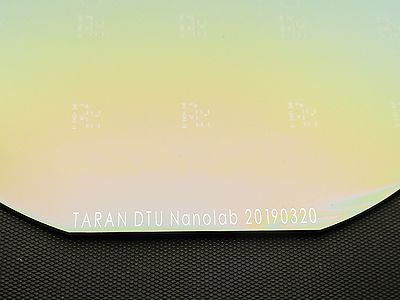

Labeling

The conversion manager software allows for inclusion of labels during the design conversion process. The labels are configured in a .lbl tab-delimited ASCII file with a special header in the first row, which must be located in the 'HIMT\Designs_conversion_PC\Labels' folder. When used, the labels defined in the label file will be merged with the pattern in the source file, and the result can be inspected in the viewer. The X and Y positions of the labels should be given in design coordinates, and will be subject to any offsets/shifts applied to the design. Note, that if the label file is changed, the job file will not update automatically.

Example of a label file:

X | Y | UNIT | HEIGHT | UNIT | TITLE

-16000 | -46000 | um | 2000 | um | TARAN DTU Nanolab 20190320

This produces a 2 mm high, approximately 32 mm long, wafer ID at the flat of a 100 mm wafer. Some special characters are not allowed (eg. ';').

Large defocus range

The standard range for the defocus parameter is -10 to 10, but a special feature allows to extend this range to -25 to 25. The large defocus range feature is set in the resist template, and can only be accessed by choosing the 'Special - Large defoc range' resist template during the job setup. The dose must be set manually, as this is an otherwise empty resist template. This feature works with both pneumatic and optical autofocus, in the full range for both.

It is possible to combine this feature with other features, such as high aspect ratio mode.

High Aspect Ratio (DOF) mode

New specs after the new writehead has been installed - section will be updated soon.

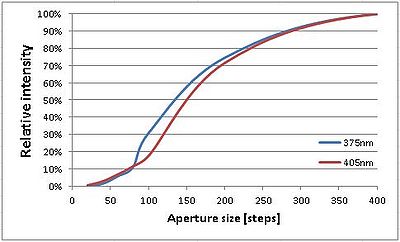

Aligner: Maskless 02 is configured with the so-called "Write Mode I", which uses a higher demagnification, higher NA lens system to achieve higher resolution. This reduces the depth of focus (technically depth of field), making it more difficult to achieve good lithographic results in thicker resist coatings. The theoretical DOF of Aligner: Maskless 02 is 0.3µm, compared to 1µm for Aligner: Maskless 01 and Aligner: Maskless 03. In order to improve processing of thick resists, the Aligner: Maskless 02 has been configured with the High Aspect Ratio Mode, which uses a variable aperture in the optical path to decrease the (illumination) NA of the system, thus increasing the DOF at the expense of intensity and resolution limit.

The aperture size is controlled via a parameter in the resist template. The high AR parameter can be Standard (aperture fully open; 800 motor steps), Large (100 steps), or X-Large (60 steps).

- Standard: No resist template or any normal resist template

- Large: 'NLAB High AR mode Large'

- X-Large: 'NLAB High AR mode XL'

Assuming a linear relation between motor steps and aperture diameter, Large corresponds to a relative aperture area of 1.6%, while X-Large corresponds to 0.6% aperture area. Intensity measurements show a relative intensity of approximately 25%, and 6%, respectively. The effective dose can be corrected by increasing the nominal dose in the exposure, either by a fixed machine parameter, or by the user setting a higher dose themselves. At the moment, the user will be required to increase the nominal dose.

Decreasing the aperture size significantly reduces the amount of light that reaches the sample, and thus the effective dose, as can be seen in the graph to the right, and the table below. The resolution limit, however, seem to be much less affected. Tests using 1.5µm MiR resist suggest that using the X-Large setting (60 steps) reduces the achievable resolution from 1µm at Standard setting to 3µm for exposure at 375nm, but only to 1.75µm for exposure at 405nm.

Dose factor for different wavelengths and aperture settings:

| 375nm | 405nm | |||

|---|---|---|---|---|

| Large (100) | X-Large (60) | Large (100) | X-Large (60) | |

| Intensity measurements | 3.3 | 17.4 | 5.7 | 14.6 |

| 150µm SU-8 acceptance test | ~3 | ~10 | NA | NA |

| 1.5µm AZ MiR 701 dose test | 7.5 | 20.8 | 6.7 | 18.0 |

| 10µm AZ 4562 dose test | ? | ? | ? | ? |

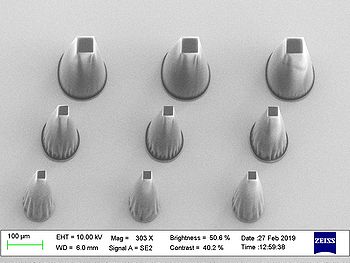

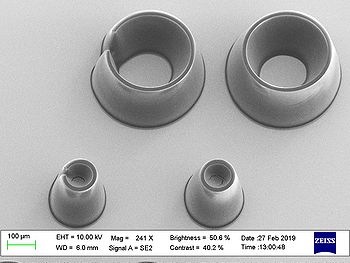

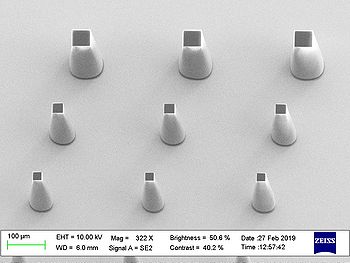

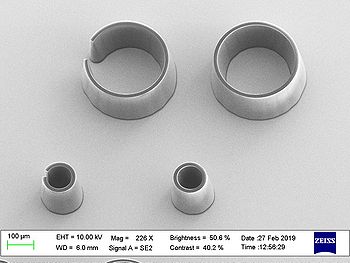

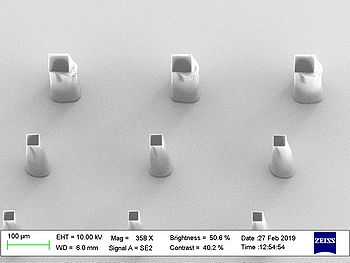

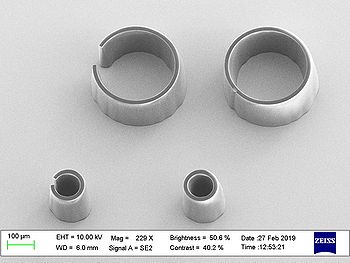

Results from acceptance test on 150µm thick SU-8:

| Pillars | Rings | |

|---|---|---|

| Standard (800)

6000 mJ/cm2 |

|

|

| Large (100)

16500 mJ/cm2 |

|

|

| X-Large (60)

55000 mJ/cm2 |

|

|

Alignment

New specs after the new writehead has been installed - section will be updated soon.

Important information regarding alignment:

After alignment to the specified alignment marks, the Aligner: Maskless 02 will automatically compensate for the translation (shift) and rotation detected during the alignment. However, the translation is set using only the first alignment mark. This means that if there is any run-out (gain) in the wafer, the alignment will be perfect at the first alignment position, while the second alignment position will be off by the run-out error. The central part of the print will be misaligned by half the run-out error. This is different compared to alignment in a mask aligner, where the user usually splits the run-out error between the two sides, resulting in good alignment in the center. In Aligner: Maskless 02, run-out may be compensated by activating the scaling function, which only becomes available when using 3 or more alignment positions. To help assess whether the measured scaling or shearing is significant, 10 ppm (scaling = 1.000010 or 0.999990; shearing = ±0.010 mRad) corresponds to a difference of 1µm from one edge to the other on a 4" wafer.

In order to get good alignment, it is advised to use four alignment marks for alignment, and to activate scaling (possibly also shearing) before starting the exposure. Optical or pneumatic auto-focus should not affect the result, but it is recommended to use the "High Res" camera for the final alignment of each mark in order to achieve the best overlay accuracy. Exposure using the fast mode decreases the overlay accuracy, since the address grid size is increased to 250 nm.

Alignment accuracy:

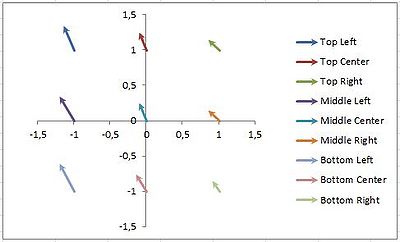

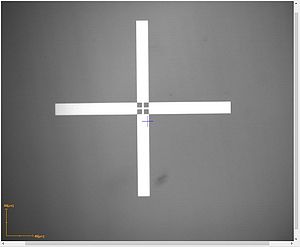

The alignment accuracy of the Aligner: Maskless 02 is a combination of the position accuracy of the stage, the accuracy of the alignment mark detection, the accuracy of the pattern already on the wafer (first print), and the calibration of the machine (correction of offset between the exposure light axis and the center of the cameras). The calibration of the machine was performed during installation, but can also be corrected if systematic offsets are observed in alignment tests. This calibration also compensates errors in the detection of the alignment marks (at least on the standard samples used for calibration and alignment tests). By measuring the stitching accuracy between two layers printed on the same substrate (without unloading the substrate), we may be able to assess the stage accuracy. By aligning to a pattern previously exposed by the Aligner: Maskless 02, or ideally by another machine, we can assess the mask-less aligner's ability to compensate for any scaling (gain) and shearing (orthogonality) errors between the two prints.

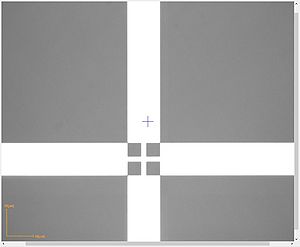

The results reported here use printed verniers to assess the misalignment along the two axes at different points on the wafer using an optical microscope. Two different designs were used; a ±5µm vernier and a ±1µm vernier. Both consist of a scale of 4µm lines with 10µm pitch, and a vernier scale to enable subdivision of the 5µm or 1µm scale into tenths, i.e. 0.5µm or 0.1µm. During inspection, observation of the symmetry of neighboring lines enables the observer to read the shifts with ±0.25µm or ±0.05µm resolution.

The measurement data is used to calculate the misalignment of the second layer with respect to the first print. The median of all measurement points in X or Y (reported as "Misalignment") is a measure of the average overall offset between the first and second print, as seen in the raw data. This alignment error has three contributions: The translational error ("Translation") is the amount by which the image is shifted; the run-in/run-out error ("Run-out") is the amount of gain in the image; and the rotational error ("Rotation") is the angle by which the image is rotated. The unit of ppm (parts per million) is used for run-out and rotation, as these errors are generally small. A run-out of 1ppm corresponds to a shift of 50nm at the edge of a 4" wafer compared to the center, while a rotation of 1ppm corresponds to an angle of 0.2" (arcseconds) or a shift of 100nm across an entire 4" wafer. For comparison, the pixel size at the wafer surface is 160nm X 160nm, and the address grid size is 40nm.

For back side alignment tests, only the alignment marks are printed in the first print. The alignment error is then assessed by first printing the scale aligned to these marks, then rotating the wafer 180° and printing the vernier scale, again aligned to the marks. The alignment error is half of the observed misalignment between the verniers. As this is an indirect measurement of the alignment error, and only a few points are generally printed, only the misalignment is reported. The run-out and rotation are believed to be similar to the ones observed for top side alignment.

In advanced field alignment, the vernier scales in the second print are printed individually (as an array, rather than as one big image), and the position of each is corrected using local alignment to one mark. The rotation, scaling, and shearing is determined and set by global alignment marks, and is the same for each individual image. For these tests, run-out and rotation can not be assessed, and only the offset is reported. Any systematic error observed here is a measure of the offset between the exposure light axis and the center of the camera, and can be used to calibrate the machine.

The deviations (±) given for the results here are calculated as half the range of measurements. If the range is smaller than the measurement uncertainty, the measurement uncertainty is used in stead. The samples used for these tests are 100mm Si wafers coated with a 1.5µm layer of positive tone resist (AZ 5214E or MiR 701).

Stage stitching test (Taran Apr 2019):

| Misalignment [µm] | Translation [µm] | Run-out [ppm] | Rotation [ppm] | ||

|---|---|---|---|---|---|

| 9 points, 60mm x 60mm | X | -0.15±0.05 | -0.16±0.05 | 0.8±1.7 | -3.6±1.2 |

| Y | 0.25±0.125 | 0.26±0.11 | -0.3±1.7 | -0.3±1.2 | |

| All 25 points | X | -0.150±0.075 | |||

| Y | 0.250±0.125 | ||||

This test was performed by printing two layers on top of each other without unloading the substrate. There is no alignment performed, so it is a test of the stages ability to address the same spot twice. The first layer was a full 4" wafer, and was printed in ~½ hour. The second layer only consisted of alignment structures in a 5x5 grid, and printed in a few minutes.

The result shows significant misalignment between the two layers, higher than what is seen in true overlay tests. This is believed to be an effect of drift during the first, long print (most likely heating of the stage), as the misalignment is seen to be biggest between parts printed furthest apart in time (i.e. on the left side of the wafer). In a normal overlay print, this error can be at least partially compensated using the scaling and shearing function available for three or more alignment marks/positions.

Top Side Alignment

New specs after the new writehead has been installed - section will be updated soon.

Overlay accuracy (spec): 0.5µm

Camera field of view (W x H):

High Res 190 µm x 140 µm

Low Res 640 µm x 480 µm

Overview 12 mm x 9 mm

Accessible stage coordinates:

High/Low Res X = ±108mm; Y = ±108mm

Overview X = ±108mm; Y = +39mm to -180mm

In order to be sure the Overview camera can be used to locate the first alignment mark, it is advised to use a mark in the bottom left portion (3rd quadrant) of the design as mark 1.

Alignment test:

| MLA-MLA | Scaling [ppm] | Shearing [mRad] | Misalignment [µm] | Translation [µm] | Run-out [ppm] | Rotation [ppm] | |

|---|---|---|---|---|---|---|---|

| 2 alignment marks

375nm, high res camera (Taran Apr 2019) |

X | NA | NA | 0.25±0.15 | 0.25±0.05 | 1.7±1.7 | 2.2±1.3 |

| Y | NA | 0.3±0.13 | 0.29±0.05 | 0.8±1.7 | 0.0±1.7 | ||

| 4 alignment marks

375nm, high res camera (Taran Apr 2019) |

X | -1 | 0.001 | 0.2±0.05 | 0.17±0.05 | -0.6±1.7 | 0.3±1.2 |

| Y | -1 | 0.4±0.05 | 0.42±0.05 | 0.6±1.7 | 0.6±1.2 | ||

| 4 alignment marks

375nm, low res camera (Taran Apr 2019) |

X | -6 | 0.002 | -0.05±0.13 | -0.06±0.05 | -1.9±1.7 | 0.8±1.3 |

| Y | -2 | 0.3±0.05 | 0.3±0.05 | -0.6±1.7 | 1.1±1.7 | ||

Alignment test with scaled first print:

| MLA-MLA | Scaling [ppm] | Shearing [mRad] | Misalignment [µm] | Translation [µm] | Run-out [ppm] | Rotation [ppm] | |

|---|---|---|---|---|---|---|---|

| 4 alignment marks

375nm, high res camera (Taran Mar 2019) |

X | 100 | 0.000 | -0.05±0.1 | -0.01±0.05 | 1.7±3.3 | 0.6±2.4 |

| Y | 101 | 0.2±0.05 | 0.18±0.05 | 0±3.3 | 0±2.4 | ||

| 4 alignment marks

375nm, high res camera (Taran Mar 2019) |

X | not used | not used | -2.75±3.0 | -2.98±0.25 | -101±8.3 | -0.6±5.9 |

| Y | not used | 3.0±2.9 | 3.12±0.25 | -96.1±8.3 | 0.0±5.9 | ||

Back Side Alignment

New specs after the new writehead has been installed - section will be updated soon.

Overlay accuracy (spec): 1.0 µm

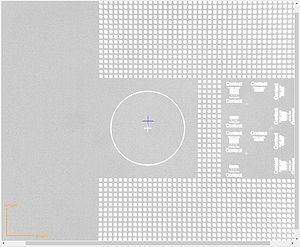

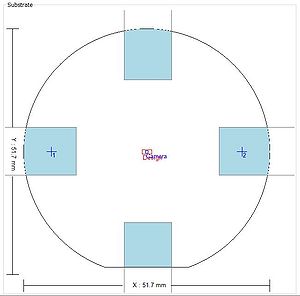

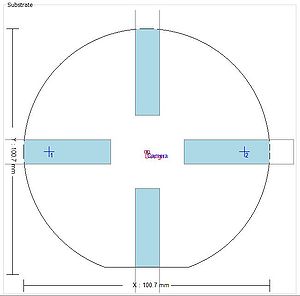

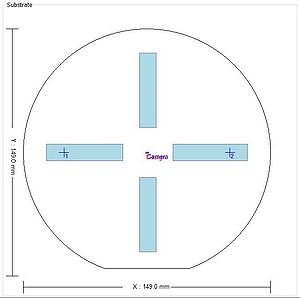

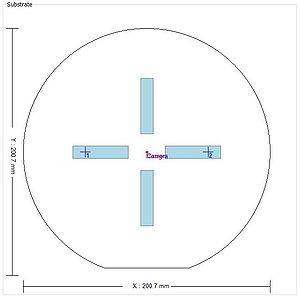

BSA windows: along the X and Y axes, 10 mm wide x 46 mm long, starting 14.5 mm from the center.

Camera field of view (W x H): 640 µm x 480 µm

The alignment marks must be placed within the BSA windows. The Overview camera only shows the top side of the substrate, and cannot be used to locate the BSA marks.

Backside alignment test:

| Misalignment [µm] | Comment | ||

|---|---|---|---|

| Align-flip180-align, 3 points 375 nm |

X | -0.625 ±0.125 | 0.5 µm verniers

Taran May 2019 |

| Y | -0.75 ±0.125 | ||

| Align-flip180-align, 3 points 405 nm |

X | -0.625 ±0.125 | 0.5 µm verniers

Taran May 2019 |

| Y | -0.375 ±0.125 | ||

| KOH-window, ? points | X | 0.0 ±0.0 | Not performed yet |

| Y | 0.0 ±0.0 | ||

Advanced Field alignment (TSA)

New specs after the new writehead has been installed - section will be updated soon.

Overlay accuracy (spec): 0.25 µm (5x5 mm2 area)

Shift, rotation, scaling, and shearing is determined and set by global alignment marks. The shift is corrected locally by automatic alignment to one mark in each field (chip).

Advanced field alignment test:

| Median [nm] | Average [nm] | ||

|---|---|---|---|

| 25 fields

375 nm, high res camera (Taran Mar 2019) |

X | 50 ±75 | 70 ±75 |

| Y | 150 ±50 | 128 ±50 | |

| Scaled first print, 10 fields

375 nm, high res camera (Taran Mar 2019) |

X | -25 ±50 | -5 ±50 |

| Y | 100 ±50 | 120 ±50 | |

| 25 fields

405 nm, high res camera (Taran Mar 2019) |

X | 100 ±75 | 108 ±75 |

| Y | 0 ±50 | 16 ±50 | |