Specific Process Knowledge/Etch/Aluminum Oxide/Al2O3 Etch with ICP Metal: Difference between revisions

Appearance

| Line 47: | Line 47: | ||

<br clear="all" /> | <br clear="all" /> | ||

==Al2O3 etching by sanvis@nanolab [[Image: | ==Al2O3 etching by sanvis@nanolab [[Image:Section under construction.jpg|70px]]== | ||

[[Media:Alumina etch information.pptx|Persentation made by Sanvis @DTU Nanolab]] | [[Media:Alumina etch information.pptx|Persentation made by Sanvis @DTU Nanolab]] | ||

Revision as of 15:38, 2 February 2023

Feedback to this page: click here

Al2O3 etching with the ICP metal

| Parameter | Recipe name: no name (testing recipe) |

|---|---|

| Coil Power [W] | 1200 |

| Platen Power [W] | 200 |

| Platen temperature [oC] | 0 |

| BCl3 flow [sccm] | 60 |

| Cl2 flow [sccm] | 30 |

| Pressure [mTorr] | 4 |

| Material to be etched | Etch rate using the above parameters |

|---|---|

| Al2O3 |

|

Al2O3 etching by sanvis@nanolab

Persentation made by Sanvis @DTU Nanolab

| Parameter | Nanoscale Al2O3 etch | Microscale Al2O3 etch |

|---|---|---|

| Coil Power [W] | 300 | 500 |

| Platen Power [W] | 15 | 70 |

| Platen temperature [oC] | 0 | 0 |

| BCl3 flow [sccm] | 20 | 40 |

| Cl2 flow [sccm] | 7 | 15 |

| Pressure [mTorr] | 1.2 | 3.0 |

| Material to be etched | Nanoscale Al2O3 etch | Microscale Al2O3 etch |

|---|---|---|

| Etch rate | 6.25 nm/min on 6" wafer, Summer sanvis@nanolab | 25 nm/min on small samples on Si carrier, Summer sanvis@nanolab |

Al2O3 etching by bghe@nanolab

Recipes

| Parameter | Recipe 1:Al2O3 etch platen only |

|---|---|

| BCl3 (sccm) | 15 |

| Ar (sccm) | 15 |

| Pressure (mTorr) | 5 |

| Coil power (W) | 0 |

| Platen power (W) | 30 |

| Temperature (oC) | 20 |

| Spacers (mm) | 100 mm |

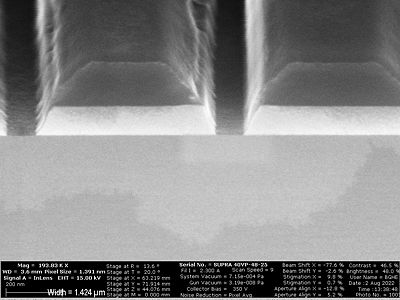

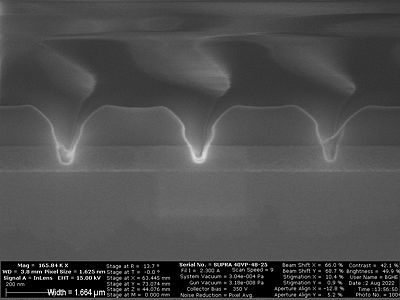

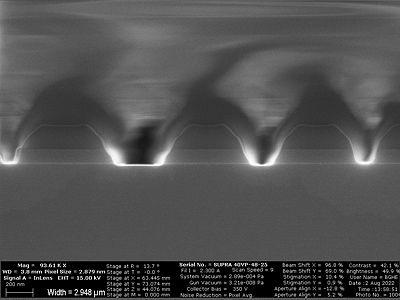

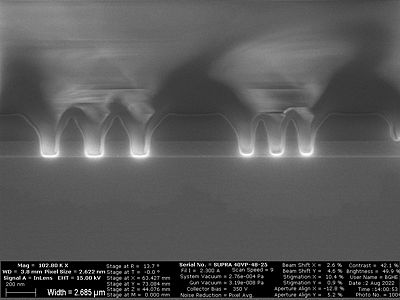

Results

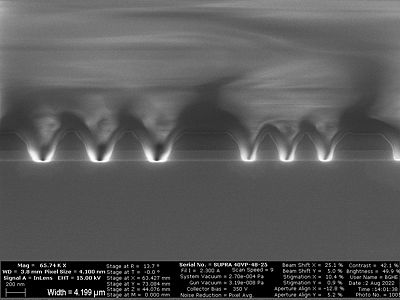

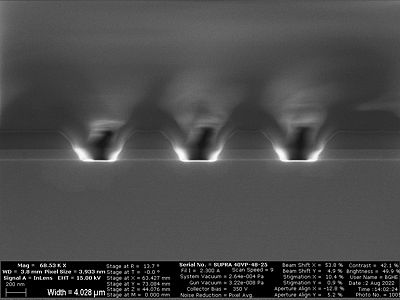

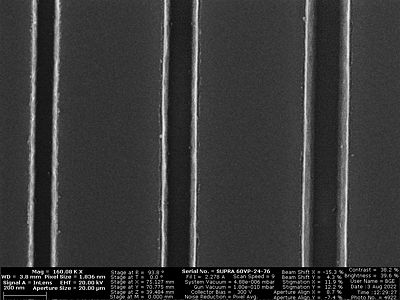

- Profile view

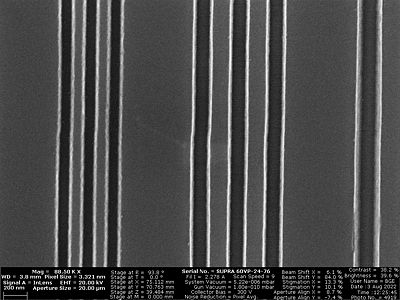

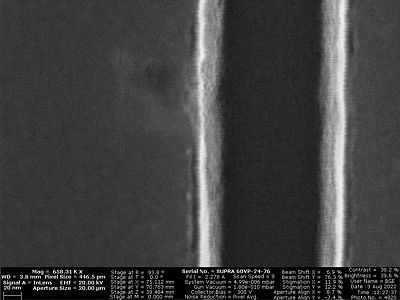

- Top view after resist strip