Specific Process Knowledge/Lithography/nLOF: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

{{:Specific Process Knowledge/Lithography/authors_generic}} | |||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Lithography/nLOF click here]''' | |||

[[Category: Lithography|Resist]] | |||

[[Category: Resist|AZ nLOF 2020]] | |||

__TOC__ | __TOC__ | ||

Revision as of 11:12, 31 January 2023

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Resist description

AZ nLOF 2020 is a negative UV photoresist, suitable for lift-off processes.

Spin coating

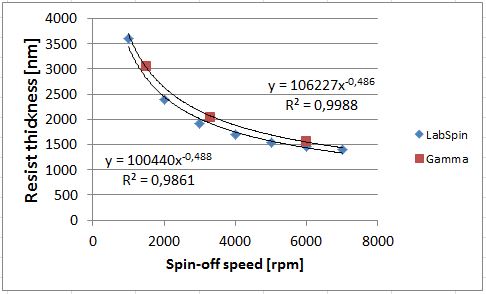

Typical spin parameters:

- Spin off: 30-60 s

- Soft bake: 60 s @ 110°C

Post-exposure bake

Typical PEB parameters:

- PEB temperature: 110°C

- PEB time: 60 s

The recommended PEB for nLOF is 60 s at 110°C, regardless of resist film thickness.

PEB baking time investigation:

While 60 s @ 110°C is adequate for Si substrates, less thermally conductive substrates (glass, III-V materials, chips bonded to carrier), have shown problems using the standard PEB recipe.

These problems were largely solved by increasing the PEB time to 120 s. Tests (on Aligner: Maskless 02) have shown that the lithographic performance of nLOF on Si is improved when using 120 s @ 110°C PEB (less stitching, less bias, more negative profile). A small report on the tests can be found here.

Development

Development speed:

- Puddle development in 2.38% TMAH (AZ 726 MIF): ~4 µm/min

A 2 µm nLOF resist film is fully developed in 20-30 s in 2.38% TMAH (AZ 726 MIF). However, the development can be continued to 60 s in order to get a more negative resist profile (due to increased under-cut).