Specific Process Knowledge/Lithography/Pretreatment: Difference between revisions

| Line 117: | Line 117: | ||

'''General comment regarding III-V materials:''' | '''General comment regarding III-V materials:''' | ||

A dehydration bake prior to spin coating can be enough, especially if adhesion is not critical, and if the resist is not left more than a day or two on the surface. Application of dip/spin-on adhesion promoter can improve the adhesion and shelf life. If adhesion is critical in the subsequent process step, application of a thin layer of SiO<sub>2</sub> using PECVD (followed by HMDS priming) as an adhesion layer is recommended. | A dehydration bake prior to spin coating can be enough, especially if adhesion is not critical, and if the resist is not left more than a day or two on the surface. Application of dip/spin-on adhesion promoter can improve the adhesion and shelf life. If adhesion is critical in the subsequent process step, application of a thin layer of SiO<sub>2</sub> using PECVD (followed by HMDS priming) as an adhesion layer is recommended. | ||

{| {{table } } | {| {{table } } | ||

Revision as of 15:15, 31 May 2021

Feedback to this page: click here

Pretreatment

This section is under construction

Pretreatment, also known as priming, is done before spin coating in order to ensure the best conditions for adhesion between the substrate surface and the resist. Pretreatment ranges from a simple dehydration bake over etching the native oxide to vapor phase deposition of an adhesion promoter. The goal of pretreatment is to remove any moisture that may be adsorbed on the surface of the substrate, and/or to modify the contact angle of the surface to match that of the resist to be coated on the substrate.

All surfaces can be divided to hydrophilic or hydrophobic surfaces. Oxidized surfaces such as SiO2 or surfaces with native oxide (e.g. Si or Al substrates) are considered to be hydrophilic and have very bad wetting with hydrophobic resist. The adhesion of most resists on hydrophilic surfaces is deteriorated if moisture is present on the surface. Therefore it is very important to do the pretreatment step before the spinning. This page gives an overview of treatments available at DTU Nanolab to promote photoresist adhesion.

Dehydration:

A dehydration bake immediately before spin coating removes the moisture adsorbed to the surface, and greatly improves the adhesion of resist on most surfaces. For thin hydrophilic layers, a few minutes on a hotplate at or above 100°C may suffice. For thicker layers or bulk oxide samples, a dehydration bake at 250°C over night is recommended. Due to the moisture in the cleanroom atmosphere, this priming naturally has a short shelf life, so spin coating should be done as soon as possible.

BHF dip:

Stripping the native oxide using BHF only works if the native oxide of the substrate is etched by BHF, and if resist has good adhesion to the substrate material itself, which basically limits it to silicon. A BHF dip leaves the surface of a silicon wafer hydrophobic, and the dangling Si-bonds are passivated by adsorbed H+. This means the surface will not oxidize immediately, but the lifetime of this passivation is limited, so it is recommended to spin coat the wafer within 20, maximum 45 minutes.

HMDS:

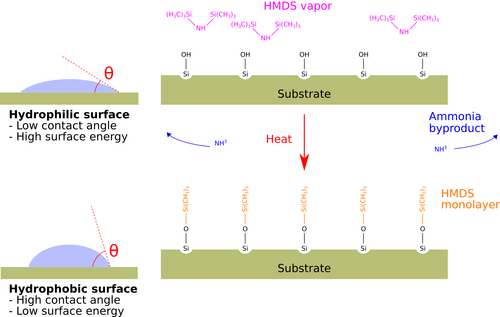

In the HMDS priming process, the -OH groups on the surface of the substrate are replaced with Si(CH3)3, thus changing the surface from hydrophilic to (more) hydrophobic. Substrates with surfaces of silicon or it's oxides or nitrides all work very well with HMDS pretreatment. Other semiconductors, insulators, or metals that form -OH groups on the surface may be suitable as well. The shelf life of substrates primed using HMDS (vapor phase) is long, maybe even several weeks.

Dip/spin-on adhesion promoter:

Adhesion promoters for dip or spin-on application are commercially available. Most are solvent based with some, usually proprietary, additives. They work by first cleaning the substrate surface, and subsequently priming the surface with the additives as the solvent evaporates.

Hard bake:

If the adhesion between the substrate surface and the resist is sufficient to survive the development process without delamination, the adhesion in subsequent process steps can be improved by a so-called hard bake. Baking the substrate a few minutes on a hotplate (or approx. half an hour in a convection oven) at a temperature higher than the soft bake temperature, e.g. 110-130°C, usually improves the adhesion between resist and surface. Depending on the type of resist used, and the temperature of the hard bake, reflow of the resist pattern may be a side effect.

Comparing pretreatment methods

| HMDS | Buffered HF-Clean | Oven 250C | |

|---|---|---|---|

| Generel description |

Vapor priming |

Native oxide strip |

Dehydration |

| Chemical |

hexamethyldisilazane (HMDS) |

12%HF with Ammoniumflouride |

none |

| Substrate size |

|

|

|

| Allowed materials |

Silicon, glass, and polymer substrates (Tg > 150°C) Film or pattern of all types, except type IV and resist/polymer |

|

|

| Restrictions | Type IV and resist/polymer on polymer substrate

i.e. no resist coated wafers or crystalbonded chips! |

Wafers with metal is not allowed | Resist is not allowed |

Pretreatment of various surfaces

General comment regarding III-V materials:

A dehydration bake prior to spin coating can be enough, especially if adhesion is not critical, and if the resist is not left more than a day or two on the surface. Application of dip/spin-on adhesion promoter can improve the adhesion and shelf life. If adhesion is critical in the subsequent process step, application of a thin layer of SiO2 using PECVD (followed by HMDS priming) as an adhesion layer is recommended.

| Dehydration | BHF dip | HMDS | Dip/spin-on adhesion promoter | Comment | |

| Silicon with native oxide | (x) | x | x | (x) | |

| Silicon oxide | (x) | x | (x) | ||

| Silicon nitride | (x) | x | (x) | ||

| Glass (borofloat/pyrex) | x | x | (x) | Dehydration before HMDS is probably best | |

| Fused silica | x | x | (x) | Dehydration before HMDS is probably best | |

| InGaAs | (x) | SurPass 3000 | |||

| GaAs | (x) | SurPass 3000 | |||

| GaP | (x) | ? | AR800-30 is being tested (leaves residue) | ||

| InP | (x) | ? | AR800-30 is being tested (leaves residue) | ||

| GaN | (x) | ? | |||

| InN | (x) | ? |

HMDS

Feedback to this section: click here

The chemical treatment with hexamethyldisilazane (HMDS) before the spin coating can be used to promote the adhesion for photoresist. Vapor priming with HMDS leaves a mono-layer of TMS (trimethylsilyl) on the Si or SiO2 surface. The process dehydrates the substrate surface, and lowers the surface tension.

The molecular formula for hexamethyldisilazane, or bis(trimethylsilyl)amine, is C6H19NSi2. Here is a schematic overview of HMDS treatment of silicon-oxide surface.

Comparing HMDS priming

| Equipment | Oven: HMDS 2 | Gamma UV/ Gamma e-beam and UV | |||

|---|---|---|---|---|---|

| Purpose |

|

| |||

| Priming chemical |

hexamethyldisilazane (HMDS) | ||||

| Performance | Contact angle |

|

Fast recipe [standard recipe]:

| ||

| Process parameters | Process temperature |

150°C |

120°C | ||

| Process time |

25 minutes |

1 min / wafer | |||

| Substrates | Substrate size |

|

| ||

| Allowed materials |

Silicon, glass, and polymer substrates III-V materials on silicon carrier Film or pattern of all but types, except type IV and resist/polymer (incl. Crystalbond) |

Silicon and glass wafers Film or pattern of all but types, except type IV and resist/polymer (incl. Crystalbond) | |||

| Batch |

1 - 25, multiple batches possible |

1 - 25 | |||

Oven: HMDS 2

The user manual, user APV, and contact information can be found in LabManager:

Process information

- Recipe 1: baseline prime process with 5 min HMDS priming time

Spin Coater: Gamma UV

The user manual, user APV, and contact information can be found in LabManager:

Spincoater: Gamma UV labmanager page

Additional information about the spin coater and processes can be found in Labadviser:

Spincoater: Gamma UV labadviser page

Spin Coater: Gamma e-beam & UV

The user manual, user APV, and contact information can be found in LabManager:

Spin Coater: Gamma e-beam & UV labmanager page

Additional information about the spin coater and processes can be found in Labadviser:

Spin Coater: Gamma e-beam & UV labadviser page

Buffered HF-Clean

Feedback to this section: click here

Another commonly used method to render the surface of silicon wafers hydrophobic is the dilute HF dip.

BHF is mostly used to do pretreatment step for new Si wafers. The native dioxide layer will be removed during 30 sec etching and in this way we will promote the resist adhesion on the Si substrates. We recommend to spin resist asap after the procedure.

The user manual, user APV, and contact information can be found in LabManager:

Buffered HF-Clean in LabManager

Process information

For more information on this BHF bath take a look here: Wet Silicon Oxide Etch (BHF)

Oven 250C

Feedback to this section: click here

The oven is typically used for pretreatment (dehydration) of Si and glass substrates to promote the resist adhesion. We recommend to place the wafers in metal carrier in the oven at least for 4 hours, better during the night, and spin the resist on them asap.

The user manual, and contact information can be found in LabManager: Oven 250C