Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4: Difference between revisions

Appearance

| Line 31: | Line 31: | ||

*[[Specific Process Knowledge/Etch/DRIE-Pegasus 4/picoscope|Addition of Picoscope oscilloscope system for process monitoring in February 2019]] | *[[Specific Process Knowledge/Etch/DRIE-Pegasus 4/picoscope|Addition of Picoscope oscilloscope system for process monitoring in February 2019]] | ||

=== Wafer bonding === | === Wafer bonding === | ||

Revision as of 16:06, 16 November 2020

Feedback to this page: click here

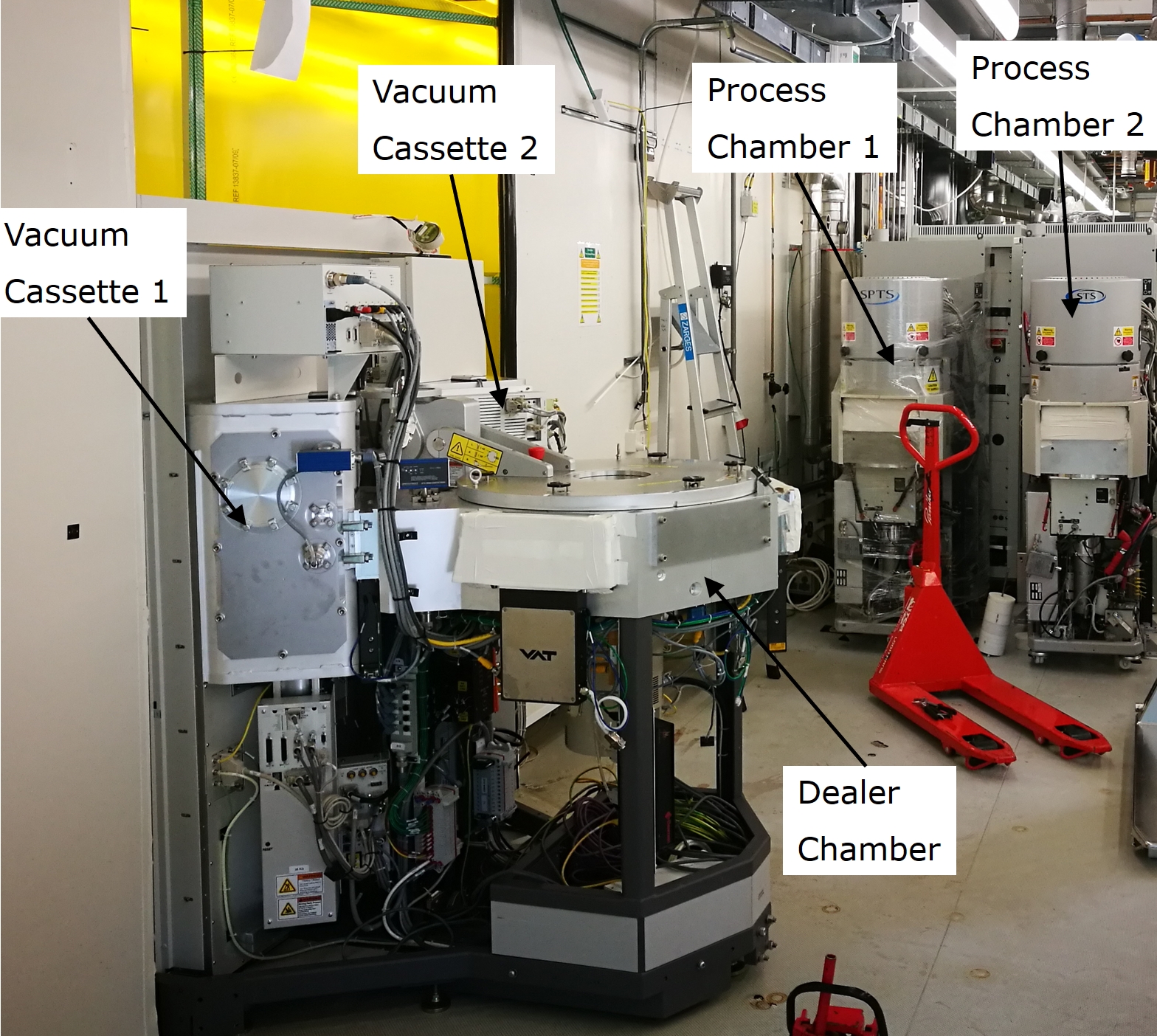

Pegasus 4 - 150mm silicon oxide and silicon nitride etching

The tool is already installed and ready to process. The picoscope, the chamber are working well right now but we still have some troubles with the wafers aligner in the loadlock.

The user manual(s), quality control procedure(s) and results, user APV(s) are not available, technical information and contact information can be found in LabManager:

Equipment info in LabManager

Process information

Hardware changes

A few hardware modifications have been made on the Pegasus 3/4 since it was installed in 2019. The changes are listed below.

Wafer bonding

To find information on how to bond wafers or chips to a carrier wafer, click here.

Internal Nanolab Process log for Pegasus 4

Process log at Nanolab [1]