Specific Process Knowledge/Lithography/Descum: Difference between revisions

Appearance

| Line 39: | Line 39: | ||

<br clear="all" /> | <br clear="all" /> | ||

===Plasma asher 2 === | ===[http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Lithography/Strip#Plasma_Asher_2 Plasma asher 2]=== | ||

[[image:descum_graf.jpg|right|frame|355x355px|Descum results plasma asher 2 - recipe 1]] | [[image:descum_graf.jpg|right|frame|355x355px|Descum results plasma asher 2 - recipe 1]] | ||

Revision as of 13:39, 5 March 2020

Feedback to this page: click here

Descum results

Plasma asher 1

Descum of AZ5214E resist on 50mm silicon wafer. Wafer was placed horisontally in chamber on a 100 mm carier wafer.

Note: Plasma asher was cold before use

| ||||||||||||||||||||||||||||||||||||||||||||||||||

Conny Hjort & Jesper Hanberg September 2019

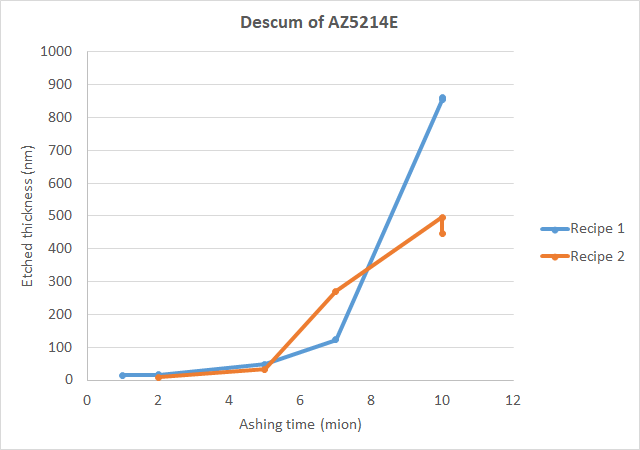

Plasma asher 2

Descum of AZ Mir 701 resist on 100mm silicon wafer. Five wafers were placed vertically in chamber.

Experiment parameters:

|

recipe 1

|

recipe 2

|

We can observe linear dependance of etched material on time after etching 7 minutes and more (recipe 2).