Specific Process Knowledge/Etch/III-V ICP/InP-InGaAsP-InGaAs: Difference between revisions

Appearance

| Line 76: | Line 76: | ||

<gallery caption="Result of InP etching." widths="500px" heights="400px" perrow="3"> | <gallery caption="Result of InP etching." widths="500px" heights="400px" perrow="3"> | ||

Image:S4_01.jpg | Image:S4_01.jpg|Top view: oxide is gone on the narrow lines, low roughness in the trenches. | ||

Image:S4_03.jpg|Top view: low roughness in the trenches. | |||

Image:S4_03.jpg | Image:S4_30dg_midt_10.jpg| 30 dg view: low roughness in the trenches | ||

Image:S4_30dg_midt_11.jpg|30 dg view: low roughness in the trenches | |||

Image: | Image:S4_midt_05.jpg: top view low roughness in trench and in the large area | ||

Image: | |||

Image:S4_midt_05.jpg | |||

</gallery> | </gallery> | ||

Revision as of 12:31, 19 June 2018

Feedback to this page: click here

InP/InGaAsP/InGaAs etch

Unselective etch for large sized features and small aspect ratios by David Larsson, DTU Photonics, 2011

| Recipe | InP Etch 1/InP Precond 1 |

| Cl2 flow | 20 sccm |

| N2 flow | 40 sccm |

| Ar flow | 10 sccm |

| Platen power | 100 W |

| Coil power | 500 W |

| Pressure | 2 mTorr |

| Platen chiller temperature | 180 oC |

| Results (InP Etch 1) | |

| Etch rate | 500-600 nm/min |

| Sidewall angle | 86-87 o |

| Selectivity (InP:SiO2, InP:HSQ) | 50:1 |

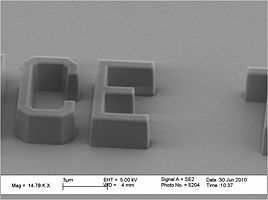

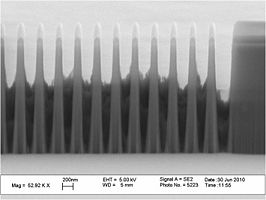

- Result of InP etching. David Larsson, DTU Photonics, 2011

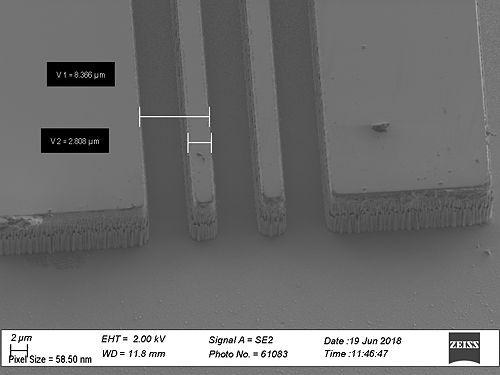

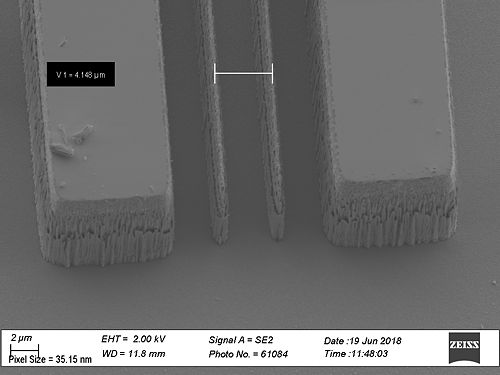

InP etching June 2018

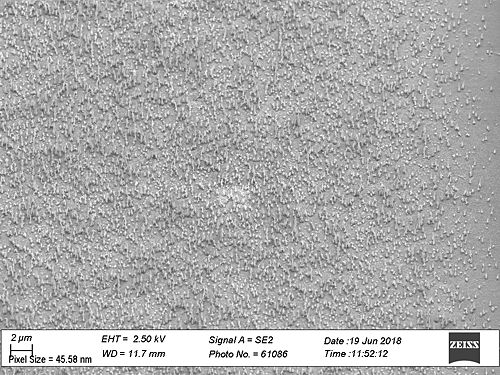

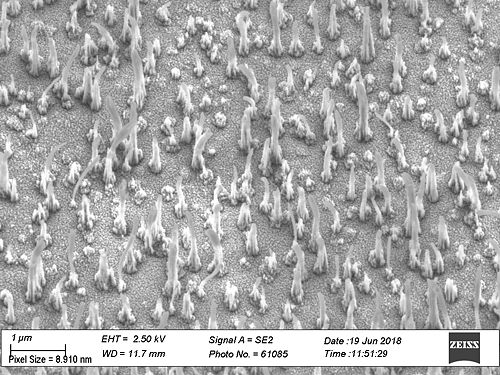

Etching of an InP piece on Si carrier

InP piece patterned with SiO2. The piece was etched on top of a Si wafer without bonding. The recipe "InP etch" was used. The roughness looks high in the bottom of the etched areas, especially in the large open areas.

- Result of InP etching.

-

low roughness in narrow trenched

-

low roughness in narrow trenched

-

A little higher roughnedd is larger trences

-

Much larger roughness in open areas

-

Zoom in on the large roughness

-

closed look at the large roughness in the open areas.

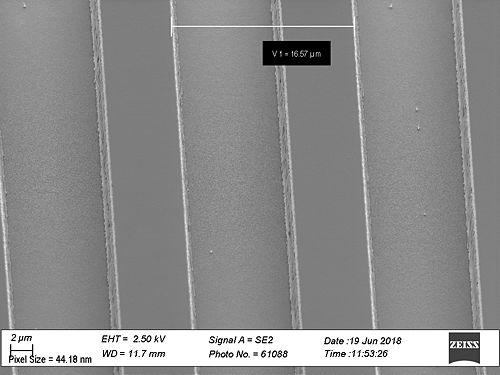

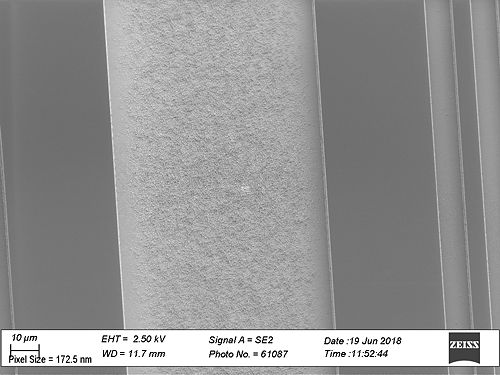

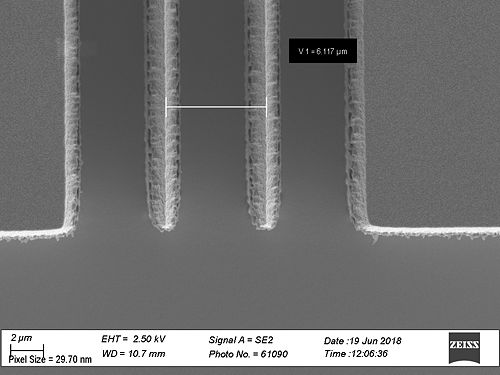

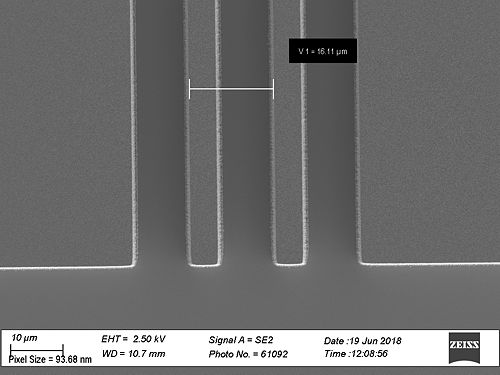

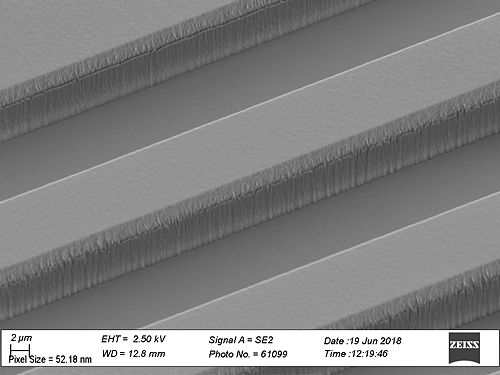

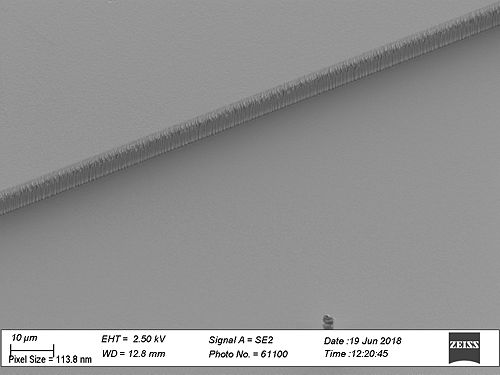

Etching of an InP piece on SiO2 carrier

InP piece patterned with SiO2. The piece was etched on top of a Si wafer coated with SiO2 without bonding. The recipe "InP etch" was used. The roughness looks low in the bottom of the etched areas, even in the large open areas.

- Result of InP etching.

-

Top view: oxide is gone on the narrow lines, low roughness in the trenches.

-

Top view: low roughness in the trenches.

-

30 dg view: low roughness in the trenches

-

30 dg view: low roughness in the trenches