Specific Process Knowledge/Lithography/PMMA: Difference between revisions

Appearance

Created page with "{|border="1" cellspacing="0" cellpadding="3" style="text-align:left;" width="90%" |- |- |-style="background:Black; color:White" |'''Resist''' |'''Polarity''' |'''Manufacturer..." |

|||

| Line 37: | Line 37: | ||

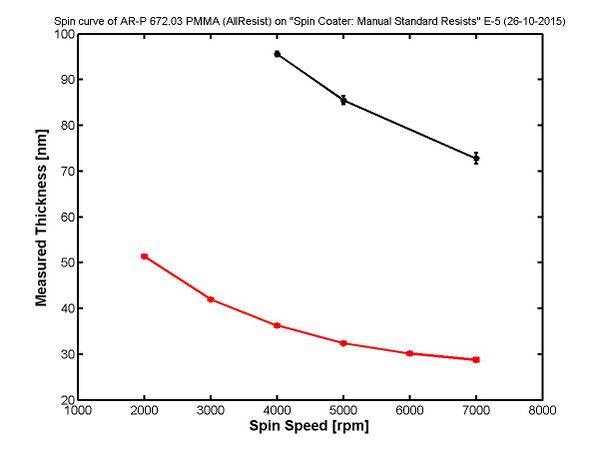

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers. | The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers. | ||

[[File:SpinCurvePMMA.jpg|right|600px]] | |||

[[File: | |||

| Line 50: | Line 46: | ||

|- | |- | ||

|-style="background:Black; color:White" | |-style="background:Black; color:White" | ||

!colspan="7"|AllResist AR-P | !colspan="7"|AllResist AR-P 672.03 (PMMA) (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||

|- | |- | ||

| Line 63: | Line 59: | ||

|- | |- | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|4000 | |||

|2000 | |2000 | ||

| | |95.55 | ||

|0.55 | |||

|0. | |||

|- | |- | ||

| Line 88: | Line 68: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|5000 | |5000 | ||

| | |2000 | ||

| | |85.50 | ||

|0. | |0.92 | ||

|- | |- | ||

| Line 104: | Line 76: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|7000 | |7000 | ||

| | |2000 | ||

| | |72.79 | ||

| | |1.18 | ||

|- | |- | ||

|} | |} | ||

| Line 118: | Line 89: | ||

|- | |- | ||

|-style="background:green; color:White" | |-style="background:green; color:White" | ||

!colspan="7"|AllResist | !colspan="7"|AllResist AR-P 672.03 (PMMA) diluted 1:1 in Anisole (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||

|- | |- | ||

| Line 176: | Line 103: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|2000 | |2000 | ||

| | |2000 | ||

| | |51.37 | ||

|0. | |0.25 | ||

|- | |- | ||

| Line 184: | Line 111: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|3000 | |3000 | ||

| | |2000 | ||

| | |41.97 | ||

|0. | |0.24 | ||

|- | |- | ||

| Line 192: | Line 119: | ||

|-style="background:WhiteSmoke; color:black" | |-style="background:WhiteSmoke; color:black" | ||

|4000 | |4000 | ||

| | |2000 | ||

| | |36.25 | ||

|0. | |0.25 | ||

|- | |- | ||

|} | |} | ||

Revision as of 14:19, 30 October 2015

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| CSAR | Positive | AllResist | Standard positive resist, very similar to ZEP520. | Allresist_CSAR62_English.pdf,, CSAR_62_Abstract_Allresist.pdf | Manual Spinner 1 (Laurell), Spin Coater Labspin | XAR-600-546, XAR-600-548, N50, MIBK:IPA | IPA | AR-600-71, 1165 Remover | Process Flow CSAR.docx |

Spin Curves

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| AllResist AR-P 672.03 (PMMA) (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 4000 | 2000 | 95.55 | 0.55 | |||

| 5000 | 2000 | 85.50 | 0.92 | |||

| 7000 | 2000 | 72.79 | 1.18 | |||

| AllResist AR-P 672.03 (PMMA) diluted 1:1 in Anisole (~ 2ml per 4" wafer) spin coated on 'Spin Coater: Manual Standard Resists, E-5, WILTID & TIGRE, 26-10-2015. Softbake 3 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 2000 | 51.37 | 0.25 | |||

| 3000 | 2000 | 41.97 | 0.24 | |||

| 4000 | 2000 | 36.25 | 0.25 | |||