Specific Process Knowledge/Etch/DRIE-Pegasus/showerheadchange: Difference between revisions

Appearance

No edit summary |

|||

| Line 8: | Line 8: | ||

|- | |- | ||

! Name/Type | ! Name/Type | ||

! Description | ! Description/parameters | ||

! Wafer ID | ! Wafer ID | ||

! Comment | ! Comment | ||

| Line 35: | Line 35: | ||

| width="100"| 1 minute, 10 degrees, 10 mTorr, 80 SF<sub>6</sub>, 150 W coil, 3 W platen | | width="100"| 1 minute, 10 degrees, 10 mTorr, 80 SF<sub>6</sub>, 150 W coil, 3 W platen | ||

| S003900 | | S003900 | ||

| 4" wafer | | 4" wafer, 50 % load | ||

| | | | ||

[[file:S003900-01.jpg |120px|frameless ]] | [[file:S003900-01.jpg |120px|frameless ]] | ||

| Line 45: | Line 45: | ||

| S00XXX | | S00XXX | ||

| | | No test yet | ||

| [[file:S00XX centre.jpg |250px|frameless ]] | | [[file:S00XX centre.jpg |250px|frameless ]] | ||

|- | |- | ||

Revision as of 15:27, 16 December 2014

Comparison of continuous processes

| Process | Before | After | |||||

|---|---|---|---|---|---|---|---|

| Name/Type | Description/parameters | Wafer ID | Comment | SEM images | Wafer ID | Comment | SEM images |

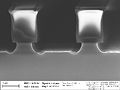

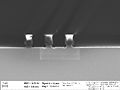

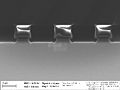

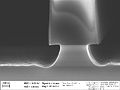

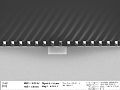

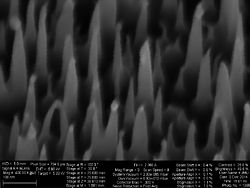

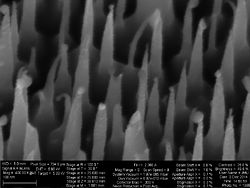

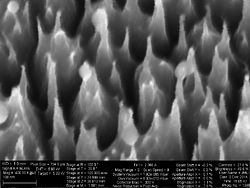

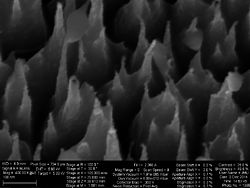

| Continuous black silicon recipe on blank wafer | 15 mins, -10 degrees, 32 mtorr, 60 sccm SF6, 55 sccm O2, 70 W platen | S004592 | Wafer centre |

|

S004679 | Wafer centre |

|

| S003900 | Wafer edge |

|

S004679 | Wafer edge |

| ||

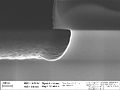

| Continuous isotropic silicon etch called isoslow7 | 1 minute, 10 degrees, 10 mTorr, 80 SF6, 150 W coil, 3 W platen | S003900 | 4" wafer, 50 % load | S00XXX | No test yet | File:S00XX centre.jpg | |

Comparison of switched processes

| Recipe | Name | Temp. | Deposition step | Etch step | Comments | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | Pres. | C4F8 | SF6 | O2 | Coil | Time | Pres. | C4F8 | SF6 | O2 | Coil | Platen | Showerhead | Runs | Key words | |||

| Process A | Step1 11 cyc | 20 | 4 | 25 | 200 | 0 | 0 | 2000 | 7.0 | 25(1.5s) 90>>150 | 0 | 350(1.5s) 550 | 5 | 2800 | 120>>140(1.5s) 45 | Old | 1 | |

| Step2 44 cyc | 4 | 25 | 200 | 0 | 0 | 2000 | 7.0 | 25(1.5s) 150 | 0 | 350(1.5s) 550 | 5 | 2800 | 140(1.5s) 45 | |||||

| Step1 11 cyc | 20 | 4 | 25 | 200 | 0 | 0 | 2000 | 7.0 | 25(1.5s) 90>>150 | 0 | 350(1.5s) 550 | 5 | 2800 | 120>>140(1.5s) 45 | New | 1 | ||

| Step2 44 cyc | 4 | 25 | 200 | 0 | 0 | 2000 | 7.0 | 25(1.5s) 150 | 0 | 350(1.5s) 550 | 5 | 2800 | 140(1.5s) 45 | |||||

| Recipe description | Name | Temp. | Deposition step | Etch step | Comments | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | Pres. | C4F8 | SF6 | O2 | Coil | Time | Pres. | C4F8 | SF6 | O2 | Coil | Platen | Showerhead | Runs | Key words | |||

| Polysilicon etch | polySi etch DUV mask | 30 | 2.3 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | Old | 1 | Slightly over-etching to ensure complete absence of grass |

| polySi etch DUV mask | 30 | 2.3 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | ||

| Cpoly1 | 30 | 1.2 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | Very aggressive, unusable | |

| Cpoly2 | 30 | 1.4 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | ||

| Cpoly3 | 30 | 1.6 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | ||

| Cpoly4 | 30 | 1.8 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | ||

| Cpoly5 | 30 | 2.0 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | New | 1 | ||