Specific Process Knowledge/Lithography/CSAR: Difference between revisions

| Line 388: | Line 388: | ||

|- | |- | ||

| | | | ||

| | | | ||

| [[File:CSAR20nmoverview-5%.png|250px]] | | [[File:CSAR20nmoverview-5%.png|250px]] | ||

| [[File:CSAR20nmoverview.png|250px]] | | [[File:CSAR20nmoverview.png|250px]] | ||

Revision as of 11:25, 7 July 2014

These tests are currently in progress and this page thus under construction. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of Chemically Semi-Amplified Resist (CSAR); a positive e-beam resist from AllResist (AR-P 6200-2).

| Equipment | Process Parameters | Comments | |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | ||

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | AR-P 6200/2 AllResist E-beam resist

60 sec at various spin speed. Acceleration 4000 s-2, softbake 1 - 5 min at 150 deg Celcius |

Disposal pipette used; clean by N2-gun before use. Use approximately 1.5 ml per 4" wafer, never use a pipette twice. Softbake is not a crucial step, see e-mail correspondence with AllResist here. | |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | |

| E-beam Exposure | |||

| JEOL 9500 E-beam writer, E-1 | Dosepattern 15nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection (CHIPAL V1) used in corner of every dose array | |

| Development | |||

| Fumehood, D-3 | 60 sec in X AR 600-54/6,

60 sec rinse in IPA, N2 Blow dry |

Gentle agitation while developing. After developing, wafer is immersed in beaker with IPA, subsequently blow dried with N2 gun. | |

| Characterization | |||

| Zeiss SEM Supra 60VP, D-3 | 2 kV, shortest working distance possible, chip mounted with Al tape | Ramona Valentina Mateiu] for further information. | |

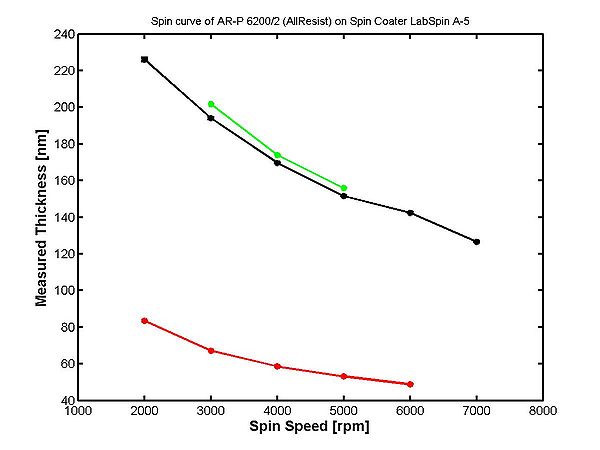

Spin Curves

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| AllResist AR-P 6200/2 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 09-04-2014. Softbake 5 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 225.98 | 0.97 | |||

| 3000 | 4000 | 194.00 | 0.6 | |||

| 4000 | 4000 | 169.57 | 0.32 | |||

| 5000 | 4000 | 151.47 | 0.26 | |||

| 6000 | 4000 | 142.38 | 0.41 | |||

| 7000 | 4000 | 126.59 | 0.36 | |||

| AllResist CSAR on Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 3000 | 4000 | 201.61 | 1.20 | |||

| 4000 | 4000 | 173.89 | 0.64 | |||

| 5000 | 4000 | 155.91 | 0.65 | |||

| AllResist CSAR 1:1 in anisole, Spin Coater: Manual LabSpin A-5, TIGRE, 16-06-2014. Softbake 2 min @ 150 degC. | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 4000 | 83.48 | 0.49 | |||

| 3000 | 4000 | 67.12 | 0.41 | |||

| 4000 | 4000 | 58.64 | 0.44 | |||

| 5000 | 4000 | 53.13 | 0.39 | |||

| 6000 | 4000 | 48.76 | 0.38 | |||

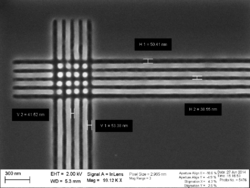

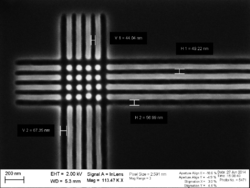

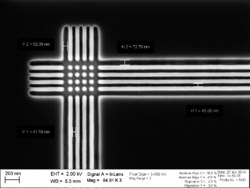

SEM pictures

140 nm CSAR

| Process | |

|---|---|

| Resist | AR-P 6200/2 AllResist E-beam resist |

| Spin Coat | 6000 rpm, 4000 1/s2, 60 sec, Softbake 1 min @ 150 degC, thickness ~140nm |

| E-beam exposure | Dose 207-242 muC/cm2 |

| Developing | SX-AR 600-54/6 60 sec, 60 sec IPA rinse |

| Coated | 2-3 nm Pt, sputtering |

| Characterization | Zeiss SEM Supra 60VP, D-3 |

50nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 |

|---|---|---|---|---|

|

|

|

| |

|

|

|

|

30nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 |

|---|---|---|---|---|

|

|

|

| |

|

|

|

|

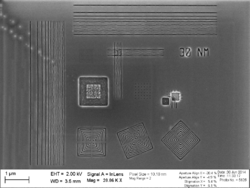

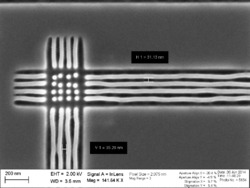

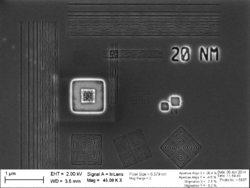

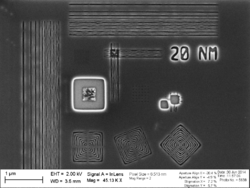

20nm

| dose [muC/cm2] | 207 | 219 | 230 | 242 |

|---|---|---|---|---|

| File:CSAR20nmoverview-5%.png |

|

|