Specific Process Knowledge/Lithography/Aligners/Aligner: Maskless 01 processing: Difference between revisions

| Line 148: | Line 148: | ||

==Alignment tests== | ==Alignment tests== | ||

In the | After installation, multiple tests were conducted in order to assess the overlay accuracy of Aligner: Maskless 01. The conclusion to the early tests were that the stage accuracy is ±0.1µm, and the machine-to-self overlay accuracy is ±0.5µm. The machine-to-machine overlay accuracy was not determined (due to the lack of a suitable mask for the mask aligners). In 2019, efforts to establish regular QC of the equipment were started, and the accuracy of the alignment mark detection has been measured regularly since 2020. While both the average and the spread of the alignment errors for the x-axis (measured in 3x3 positions covering a 60x60mm<sup>2</sup> area) has consistently been within the ±1µm specification of the machine, the spread of the alignment errors for the y-axis is typically 3±1µm, despite the average error being in spec, due to negative offsets on the upper half of the wafer and positive offsets on the lower. In 2025, it was decided to investigate this problem further, in order to determine whether a specific alignment protocol could remedy the alignment error, or whether the acceptance limits for the QC would have to be changed. | ||

The | The samples used for these tests are 100mm Si wafers coated with a 1.5µm layer of the positive tone resist AZ 5214E. The deviations (±) given for the results here are calculated as half the range of measurements. If the range is small, the measurement uncertainty is used in stead. | ||

In the MLA1-MLA1 tests, the design consists of ±5µm verniers with 0.1µm resolution along the X and Y axis placed in a 3 by 3 matrix covering a 60mm by 60mm area centered on the wafer. The sample is loaded, and the first layer (the linear scales) is printed. Without unloading, the second layer (the vernier scales) is printed on top of the first, and then the sample is developed. | |||

Revision as of 14:57, 11 December 2025

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Exposure technology

Aligner: Maskless 01 is not a direct laser writer. In the maskless aligner, the exposure light is passed through a spatial light modulator, much like in a video projector, and projected onto the substrate, thus exposing an area of the design at a time. The substrate is exposed by stepping the exposure field across the substrate.

The light source is a 10W 365nm LED with a FWHM of 8nm. The spacial light modulator is an 800 X 600 pixel digital micro-mirror device. The individual mirrors of the DMD are switched in order to represent the design, and are timed in order to yield the desired exposure dose, while taking into account illumination uniformity, soft-stitching, and possibly also sub-pixel features. This image is projected onto the substrate through a lens(system). The projected image yields a writing field of 400µm X 300µm, and thus a pixel size of 0.5µm X 0.5µm at wafer scale. This writing field is stepped across the substrate, in order to expose the entire design, each field overlapping slightly in order to minimize stitching errors.

The writing head of the Aligner: Maskless 01 moves only in the z-direction. Using a pneumatic focusing system, the maskless aligner is able to do real-time autofocus. The defocus process parameter is used to compensate offsets in the focusing mechanism, and to optimize printing quality in different resists and varying thicknesses. The stage of the Aligner: Maskless 01 moves only in x and y. It has no theta-axis. All rotation during alignment is thus accomplished by transformation of the input design.

Process Parameters

Exposure dose and defocus

Information on UV exposure dose

Writing speed

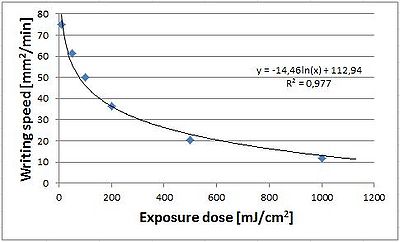

The site acceptance test performed during the installation of the Aligner: Maskless 01 showed an exposure time/speed of 0.025 min/mm2, which is slightly lower than the 0.02 min/mm2 given in the specifications. At such speeds, a full 4" design would take 2:30-3:15 hours to expose. In practice, we observe exposure times in excess of 2 hours for a full 4" design.

The exposure time increases linearly with exposure dose and writing area. However, due to the stepped nature of the exposure, the exposure time as a function of fill factor is highly nonlinear. It takes the same time to expose a single pixel as an entire 300µm X 400µm writing field, so the exposure time depends on the number of addressed writing fields, rather than on the fill factor of the design. In practice, there will probably not be much variation in exposure time with fill factor. Exposure tests using a 50mm2 design have shown that the exposure time increases linearly from 40s at 10mJ/cm2, to 257s at 1000mJ/cm2. The fill factor of the design is 39%, but ~80% of the area is addressed by the writing fields. Scaled to a full 4" wafer, the exposure time is estimated to 2:37 hours at a dose of 100mJ/cm2.

Resolution

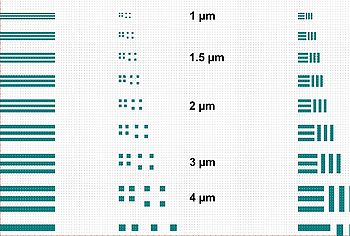

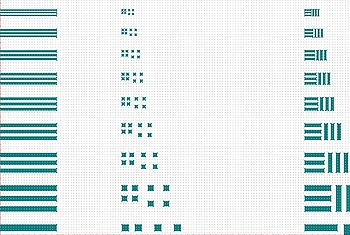

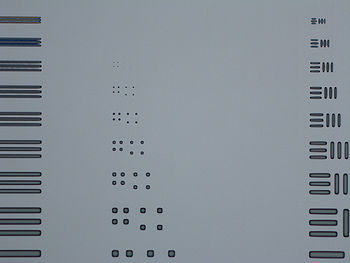

The pixel-size of the DMD in the Aligner: Maskless 01 is 0.5µm X 0.5µm (at the sample surface). The lithographic resolution of the machine is 1µm on paper, which was demonstrated in the acceptance test after installation using a resist thickness of 0.5µm. This result has later been confirmed. In 1.5µm thick resist, the resolution is around 2µm.

The table below shows the result of a resolution test using 1.5µm and 0.5µm positive resist. For 1.5µm resist the resolution is 2µm, maybe even a little lower, while it is 1µm, or at least close to, for 0.5µm resist. The optimal dose depends on the designed structures; dots require a lower dose in order to print to size than lines. In the case of a dark field design, trenches would probably require a lower dose in order to print to size than lines, while holes would require a higher dose to print than trenches.

Also evident in the pictures is the optical proximity effect (not to be confused with the proximity (gap) effect in contact lithography); corners are rounded, and the smallest lines show a different width for the central line compared to the outer ones. Optical Proximity Correction is the practice of augmenting the design in order achieve the desired size and shape in the finished print. A basic form of OPC is corner correction, also known as serifs, where a small square is added or subtracted at all corners. The last column in the table show the effect; the dots become square, and the short lines are the correct length. The effect of corner correction is significant below 2µm, but negligible above 4µm. The proximity effect on the width of the outer lines is not removed by corner correction; here so-called SRAFs (Sub-Resolution Assist Feature), also known as scatter bars, would be needed.

| As designed | With OPC (0.5µm corner corrections/serifs) | |

|---|---|---|

| Design file |

|

|

| 1.5µm AZ 5214E

Dose: 80, defoc: -3 Development: SP 60s |

|

|

| 0.5µm AZ 5214E (diluted)

Dose: 80, defoc: -3 Development: SP 30s |

|

|

Substrate positioning

During load, the machine will focus on the surface of the sample. Then, using the pneumatic focusing system, it will detect the edges of the sample (this function dependes on the substrate template used) in order to determine the center of the sample. The following results rapport findings using the "4 inch wafer" template on a standard 100mm Si substrate.

Substrate centring

During (4") substrate detection, the sample is scanned along the X- and Y-axes, as well as diagonally. From these measurements, the diameter of the substrate is calculated, as well as the stage position matching the center of the substrate. This stage position will be the default origin for the subsequent exposure.

Unfortunately, the centering does not compensate for major or minor flats. The center position will therefore typically be displaced several hundred µm from the center of the substrate along the Y-axis due to the major flat, and possibly also shifted due to any minor flats. These shifts have successfully been compensated during file conversion, which yielded a centering accuracy of ±200µm. The table below lists the corrections needed during file conversion in order to compensate for shifts due to major and minor flat, dependent on the position of the minor flat. Keep in mind that the tolerances of substrate diameter and flat lengths in the SEMI wafer standard introduce uncertainties to these numbers in the order of 0.4-0.9mm. Accurate positioning of the design relative to the substrate center would require measurement of diameter and flat lengths of the individual substrate, and subsequent recalculation of the correction values.

| Minor flat position | X correction [mm] | Y correction [mm] |

|---|---|---|

| none | 0 | -1.35 |

| left | -0.4 | -1.35 |

| up | 0 | -0.95 |

Flat alignment

At the end of (4") substrate detection, the sample is scanned twice along the flat, in order to determine the substrate rotation. This angle will be presented in the exposure panel along with the option to expose the design rotated in order to compensate for this angle, i.e. aligned to the flat.

The flat alignment accuracy has been measured to be 0±0.1° (1.7mRad) quite consistently. Out of a total of 15 exposures, 13 showed misalignment of 0.1° or better, despite initial sample rotations exceeding 5°.

Please observe, that one should not select the flat alignment option if 'Expose Crosses' is used. The design will be rotated, but the crosses will not, resulting in a subsequent alignment error equal to the flat angle.

Alignment

The alignment accuracy of the Aligner: Maskless 01 is a combination of the position accuracy of the stage, the accuracy of the alignment mark detection (mostly determined by the offset between camera and stage), and the accuracy of the pattern already on the wafer (first print).

By measuring the stitching accuracy between two layers printed on the same substrate (without unloading the substrate), we can assess the stage accuracy. By aligning to a pattern previously exposed by the Aligner: Maskless 01, we can assess the mark detection accuracy. And finally, by aligning to a pattern exposed on a different aligner, we can assess the mask-less aligner's ability to compensate for any scaling and orthogonality errors between the two machines.

Important note about correction options

You must use all available alignment corrections!

- 2 point alignment can only correct for rotation

- 3+ point alignment can correct for rotation, scaling and shearing - you must use all 3 alignment corrections!

The stage of Aligner: Maskless 01 has suffered some kind of damage (maybe during it's relocation to E-4 in 2019), which means the stage positioning is distorted. When aligning to a pattern exposed using a different machine, we typically see a shearing on the order of 0.1 rad, i.e. the axes are not orthogonal, but even when aligning to patterns exposed on Aligner: Maskless 01 itself, this distortion results in misalignment unless a specific procedure is followed.

When aligning on Aligner: Maskless 01, you should either:

- Use only 2 alignment marks and apply rotation correction

- Use 3+ alignment marks and apply all corrections (rotation, scaling and shearing)

Using only two alignment marks is usually fine for smaller chips, but when exposing full wafers there may be misalignment, especially if previous prints are made on a different machine. With 4 alignment marks and all corrections applied, the best alignment accuracy is obtained for all substrates.

If four marks are used, but scaling and shearing is not applied, significant misalignment will be observed, even on chips. On a 4" wafer the shift in Y can be several hundred µm.

Alignment tests

After installation, multiple tests were conducted in order to assess the overlay accuracy of Aligner: Maskless 01. The conclusion to the early tests were that the stage accuracy is ±0.1µm, and the machine-to-self overlay accuracy is ±0.5µm. The machine-to-machine overlay accuracy was not determined (due to the lack of a suitable mask for the mask aligners). In 2019, efforts to establish regular QC of the equipment were started, and the accuracy of the alignment mark detection has been measured regularly since 2020. While both the average and the spread of the alignment errors for the x-axis (measured in 3x3 positions covering a 60x60mm2 area) has consistently been within the ±1µm specification of the machine, the spread of the alignment errors for the y-axis is typically 3±1µm, despite the average error being in spec, due to negative offsets on the upper half of the wafer and positive offsets on the lower. In 2025, it was decided to investigate this problem further, in order to determine whether a specific alignment protocol could remedy the alignment error, or whether the acceptance limits for the QC would have to be changed.

The samples used for these tests are 100mm Si wafers coated with a 1.5µm layer of the positive tone resist AZ 5214E. The deviations (±) given for the results here are calculated as half the range of measurements. If the range is small, the measurement uncertainty is used in stead.

In the MLA1-MLA1 tests, the design consists of ±5µm verniers with 0.1µm resolution along the X and Y axis placed in a 3 by 3 matrix covering a 60mm by 60mm area centered on the wafer. The sample is loaded, and the first layer (the linear scales) is printed. Without unloading, the second layer (the vernier scales) is printed on top of the first, and then the sample is developed.

In the overlay test, two alignment accuracies are assessed: The machine-to-self overlay accuracy (MLA-MLA), and the machine-to-machine (MA6-MLA) overlay accuracy. Because alignment is possible using two marks or four marks, both are tested in each case. Exposing the first print with or without flat alignment was also tested, but no significant effect was observed.

In the MLA-MLA overlay test, the design is the same as for stitching; ±5µm and ±1µm verniers along the X and Y axis placed in a 3 by 3 matrix covering a 60mm by 60mm area centered on the wafer. The sample is loaded, and the first layer (the linear scales) is printed. The sample is unloaded and developed. The second layer (the vernier scales) is aligned to marks contained in the first layer, and then the sample is developed again. The alignment marks used for 2 mark alignment are placed 60mm apart on the X axis, while the marks used for 4 mark alignment are placed at the corners of a 60mm by 30mm rectangle.

The results in the table below show an alignment error of -2µm in X. They also show that including the scaling and shearing of the axes calculated by the machine from alignment to four marks in the exposure only seems to introduce a gain error in Y. However, if the wafer has significant bow or other distortions due to processing of the first layer, scaling and/or shearing correction may be necessary.

Since the alignment error in X seems so consistent, the machine was calibrated by correcting the X-axis beam off-set 2µm in the machine configuration files. As seen below, this removed the alignment error, and suggests that the machine-to-self overlay accuracy of the Aligner: Maskless 01 is ±0.5µm or better.

| MLA-MLA | Scaling [ppm] | Shearing [mRad] | Misalignment [µm] | Translation [µm] | Run-out [ppm] | Rotation [ppm] | |

|---|---|---|---|---|---|---|---|

| 2 alignment marks

(three samples) |

X | NA | NA | -2.08±0.25 | -2.07±0.25 | -2.31±8.33 | 1.02±1.67 |

| Y | NA | -0.33±0.18 | -0.34±0.19 | 1.20±1.67 | -0.46±5.89 | ||

| 4 alignment marks

(three samples) |

X | 1±2 | 0.002±0.001 | -2.08±0.25 | -2.08±0.25 | -3.70±8.33 | 0.56±1.67 |

| Y | -12±1 | -0.22±0.35 | -0.21±0.08 | -6.30±1.67 | -0.93±5.89 | ||

| 2 alignment marks

after calibration (three samples) |

X | NA | NA | -0.22±0.25 | -0.19±0.19 | 1.85±2.08 | -0.09±2.92 |

| Y | NA | -0.28±0.38 | -0.28±0.13 | 4.35±5.97 | -0.09±2.64 | ||

In the MA6-MLA overlay test, a mask from an existing design (GreenBelt METAL v2, dark field) is reused to print the first layer using the Aligner: MA6-2, and the sample is developed. The second layer is aligned and printed in Aligner: Maskless 01, using a design containing four sets of ±5 vernier scales located at the corners of a ~90mm by ~3mm rectangle, before being developed again. For 2 mark alignment, the original alignment marks at X±~43mm are used. Since only two alignment marks exist in the original design, four corners (positioned in a ~60mm by ~60mm square pattern) are used for manual alignment in the 4 mark test. Using corners rather than crosses reduces the accuracy of the alignment, as the positions of corners are subject to shifts due to bias in the first print lithography.

The results in the table below reproduce the alignment error in X seen in the machine-to-self overlay tests (should be better now that the machine has been calibrated). Due to the close proximity of the verniers in Y, run-out and rotation have not been calculated for that axis. But the X axis shows some run-out, consistent with alignment between two stages (the mask writer and the maskless aligner) without scaling compensation. The fact that using scaling and shearing compensation doesn't remove this gain, and seems to add a significant rotation error, is probably more due to the alignment "marks" used than to the machine itself. More tests using a purpose-designed mask would have to be conducted in order to estimate the machine-to-machine overlay accuracy of the Aligner: Maskless 01.

| MA6-MLA | Scaling [ppm] | Shearing [mRad] | Misalignment [µm] | Translation [µm] | Run-out [ppm] | Rotation [ppm] | |

|---|---|---|---|---|---|---|---|

| 2 alignment marks | X | NA | NA | -1.50±0.75 | -1.50±0.25 | 6.94±5.56 | 2.78±3.89 |

| Y | NA | 0.00±0.25 | 0.00±0.25 | NA | NA | ||

| 4 alignment marks | X | -8 | 0.005 | -1.75±0.63 | -1.69±0.25 | 6.25±5.56 | -12.5±3.89 |

| Y | 13 | 0.25±0.63 | 0.19±0.56 | NA | NA | ||

Optimal use of the maskless aligner

As seen in the section on writing speed, the exposure speed of Aligner: Maskless 01 is around 0.02min/mm2, or 50mm2/min, at a dose of 100mJ/cm2, yielding exposure times in excess of 2 hours for a 4" wafer. At this exposure speed, we would quickly run into a bottleneck as more and more users expose more and more wafers, if full 4" designs are used all the time. Another concern is that the exposure dose seems to be unstable over long exposure times, as consecutive exposures using the same parameters have been observed to yield different lithographic results. The conclusion is that exposure using the maskless aligner requires a different design philosophy than when a mask aligner is used for the exposure.

Design philosophy

In order to effectively use the Aligner: Maskless 01, we need to steer away from the "as many variations of the design as possible" approach typically used in mask design when the design of a device is in it's test phase. Instead, we should print only one or a few devices at a time, and iterate the design based on the performance of that device, thus truly making use of the rapid prototyping capabilities of the maskless aligner.

Alternatively, we should split our design into two parts; one comprising of all the parts of the device that remain constant through the iterations, e.g. contacts, and the other part being the part of the device that is subject to design optimization. The first part should be printed using a mask aligner, while the other design can be printed much faster on the maskless aligner due to the significantly reduced exposure area. This method is especially useful if the two exposures can be done in the same layer of resist using mix-and-match resist/process.

Mix-and-match

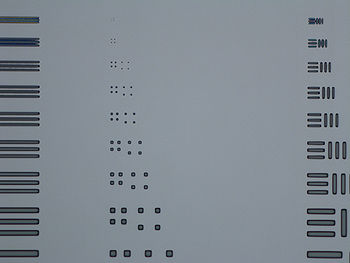

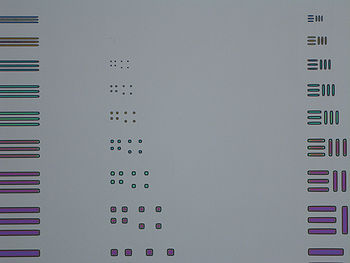

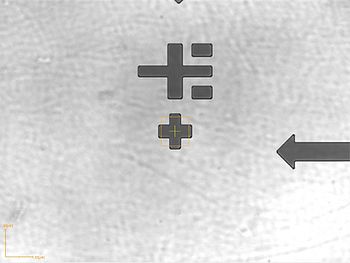

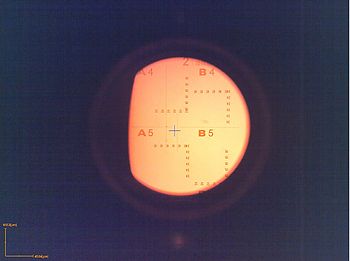

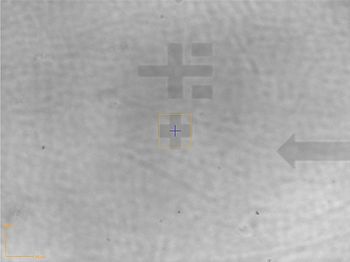

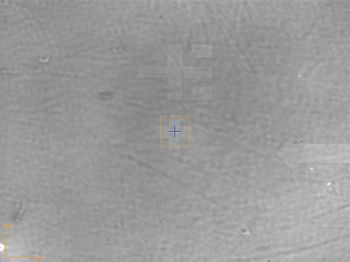

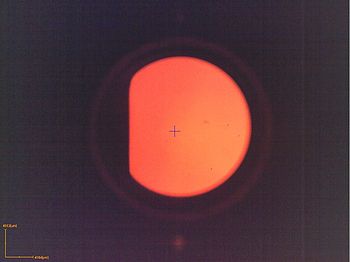

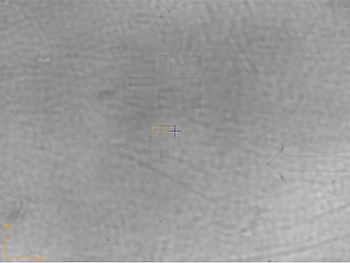

In order to establish a mix-and-match process for Aligner: Maskless 01, different resists have been tested by exposing them in a mask aligner, and subsequently aligning and exposing using Aligner: Maskless 01. Screen dumps taken during the alignment procedure may be seen in the table below. All these tests were carried out on 4" Si wafers.

The easiest approach to mix-and-match is to use a (simple) positive tone resist, such as AZ 5214E, and develop the pattern after the first exposure. The remaining resist can be exposed using the same parameters as normal, and there is plenty of contrast for the alignment process. This process can also be used if the maskless aligner is used first.

Alternatively, the post-exposure bake and/or development after first exposure can be skipped. This enables the use of AZ MiR 701, without the drop in sensitivity usually associated with a post-exposure bake at a higher temperature than the soft bake. The contrast of the alignment mark, however, is greatly reduced, making alignment more difficult. AZ MiR 701 shows more contrast than AZ 5214E, but in both cases the focus and brightness has to be optimized in order to make automatic alignment possible. The design may also have to be adapted, as the poor contrast makes navigation using the overview camera difficult. Also, a less reflective substrate than Si, e.g. oxidized Si, may complicate alignment further.

In the case of negative tone resist, such as AZ nLOF 2020, there is no contrast after exposure, making alignment impossible. Performing post-exposure bake before the second exposure yields a slight contrast, but in the case of nLOF the automatic alignment failed. Manual alignment was possible, but the alignment accuracy may suffer. For nLOF, the post-exposure bake temperature is the same as the soft bake, and post-exposure baking several times should not be a problem.

| High resolution camera | Overview camera | |

|---|---|---|

| AZ 5214E

Exposed + developed |

|

|

| AZ MiR 701

Exposed only |

|

|

| AZ 5214E

Exposed only |

|

|

| AZ nLOF 2020

Exposed + PEB |

|

|