Specific Process Knowledge/Thin film deposition/Cluster-based multi-chamber high vacuum sputtering deposition system: Difference between revisions

| Line 227: | Line 227: | ||

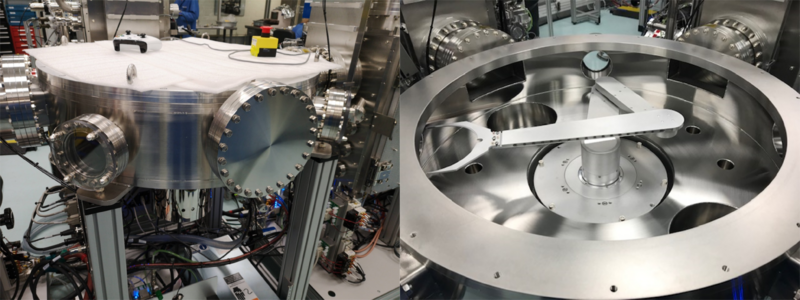

The second process chamber called PC3 consists of two KJLC Torus® 3" magnetron sputtering sources and one height-adjustable KJLC Torus® 4" magnetron sputtering source, also with the possibility of RF, DC, Pulse DC and HiPIMS sputtering. It is possible to apply an RF bias on the substrate, which can be used to clean the substrate before the deposition or used during the deposition to alter the film properties. The chamber allows co-sputtering (sputtering of two or more sources at the same time) as long as the sources are not sharing the same power supply. A residual gas analyzer (RGA) mounted on the chamber allows monitoring post-process chemical gas traces. In order to operate the analyzer, the chamber should be pumped to base pressure. | The second process chamber called PC3 consists of two KJLC Torus® 3" magnetron sputtering sources and one height-adjustable KJLC Torus® 4" magnetron sputtering source, also with the possibility of RF, DC, Pulse DC and HiPIMS sputtering. It is possible to apply an RF bias on the substrate, which can be used to clean the substrate before the deposition or used during the deposition to alter the film properties. The chamber allows co-sputtering (sputtering of two or more sources at the same time) as long as the sources are not sharing the same power supply. A residual gas analyzer (RGA) mounted on the chamber allows monitoring post-process chemical gas traces. In order to operate the analyzer, the chamber should be pumped to base pressure. | ||

<gallery caption="Process chamber PC 3" widths=" | <gallery caption="Process chamber PC 3" widths="400px" heights="350px" perrow="2"> | ||

image:PC3_photo.png| Photo of the chamber. | image:PC3_photo.png| Photo of the chamber. | ||

image:PC3_during_sputtering.png| Deposition from source 2. | image:PC3_during_sputtering.png| Deposition from source 2. | ||

Revision as of 16:37, 28 July 2025

Feedback to this page: click here

Unless otherwise stated, this page is written by DTU Nanolab internal

All images and photos on this page belonges to DTU Nanolab.

The cluster-based multi-chamber high vacuum sputtering deposition system is a robotic cluster tool with two deposition chambers sharing the same distribution trasfer station and the load-lock. The equipment has been installed and accepted in the clean-room during January of 2020. The purpose of the tool is to deposit a variety of materials using DC/RF/PulseDC/HIPIMS magnetron sputtering with or without RF substrate bias.

In PC 1 (process chamber 1) it is possible to deposit any material using 6 x 3” magnetrons sources with N2 or O2 reactive gases.

PC 3 (process chamber 3) is dedicated to oxygen free materials - nitrides and metals. It is equipped with 1 x 4” + 2 x 3” magnetrons and supplied with N2 process gas for reactive deposition. Both chambers allow heating of substrates up to 600 oC. The equipment is located in cleanroom A-5 where the user can acces the cassette loader.

Manufacture: Kurt J. Lesker Company

Model: 2017 PRO Line PVD75 thin film deposition cluster system

The user manual, user APV and contact information can be found in LabManager:

Sputter-System Metal-Oxide(PC1)

Sputter-System Metal-Nitride(PC3)

The Thin Film group thinfilm@nanolab.dtu.dk is responsible for the equipment.

Target/Metal requests should be sent to metal@nanolab.dtu.dk.

If you need a training on the machine please send your request to: training@nanolab.dtu.dk.

Sputtering deposition system set-up

The cluster sputter system is used for deposition of metals, magnetic metals and dielectrics on a single 4" or 6" wafer or several small samples. Samples will be placed on the ten-shelf cassette and loaded in the load lock module. After the load lock chamber is pumped down, the sample can be transferred to the desired process chamber. The sample will be rotated over the target and can be heated up to 600 °C while depositing the film. The system is equipped with two process chambers connected to a wafer transfer robot and a load lock chamber.

- System set-up and power supply configuration.

-

The system set-up showing the different operation chambers and power supplies network.

*HSM - High Strengh Magnet.

**RGA - Residual Gas Analyser.

Power supply configuration

Power supply specifications are presented in a table below.

| Power Supply ID | Type | Maximum output power (W) | Maximum output voltage (V) | Maximum output current (A) | Comments

|

|---|---|---|---|---|---|

| PC1 Power Supply 1 | RF | 300 | |||

| PC1 Power Supply 3 | DC | 500 | 1000 | 4 | |

| PC1 Power Supply 4 | DC | 500 | 1000 | 4 | |

| PC1 Power Supply 5 | Pulse DC | 2000 | 800 | 5 |

Max frequency: 100kHz |

| PC1 Power Supply 7 | RF (Substrate) | 100 | |||

| PC3 Power Supply 1 | RF | 300 | |||

| PC3 Power Supply 2 | Pulse DC | 2000 | 800 | 5 |

Max frequency: 100kHz |

| PC3 Power Supply 3 | DC to HiPIMS | 1500 | 1000 | 4 |

HiPIMS Unit

|

| PC3 Power Supply 5 | DC | 500 | 1000 | 4 |

|

| PC3 Power Supply 6 | RF (substrate) | 100 |

Sputter-System Metal-Oxide (PC1)

Chamber PC1 consists of six KJLC Torus® 3" magnetron sputtering sources with possibility of RF, DC, Pulse DC and HIPIMS sputtering. There are Argon, Nitrogen and Oxygen gas lines connected to this chamber. It is possible to apply an RF bias to the substrate, which can be used for substrate cleaning before the deposition or used during the deposition to alter the film properties. Deposition of magnetic materials requires the high strength magnet (HSM), which must be installed on source 3 in PC1. The chamber allows co-sputtering (sputtering of two or more sources at the same time) as long as the sources are not sharing the same power supply.

- Process chamber (PC 1)

-

Photo of the chamber.

-

Deposition from source 2.

Sputter-System Metal-Nitride (PC3)

The second process chamber called PC3 consists of two KJLC Torus® 3" magnetron sputtering sources and one height-adjustable KJLC Torus® 4" magnetron sputtering source, also with the possibility of RF, DC, Pulse DC and HiPIMS sputtering. It is possible to apply an RF bias on the substrate, which can be used to clean the substrate before the deposition or used during the deposition to alter the film properties. The chamber allows co-sputtering (sputtering of two or more sources at the same time) as long as the sources are not sharing the same power supply. A residual gas analyzer (RGA) mounted on the chamber allows monitoring post-process chemical gas traces. In order to operate the analyzer, the chamber should be pumped to base pressure.

- Process chamber PC 3

-

Photo of the chamber.

-

Deposition from source 2.

Distribution Chamber (Genmark robot)

The load-lock and process chambers PC1 and PC3 are connected through the common distribution chamber. The robot arm can transfer the sample to the selected destination. During normal operation, the chamber is pumped to a base pressure ensuring the safe transfer of the sample between chambers and load-lock without breaking a vacuum. The unit is connected to its own turbo-pump.

- Distribution chamber (Robot). View from the service area.

-

The distribution chamber with and without the top cover.

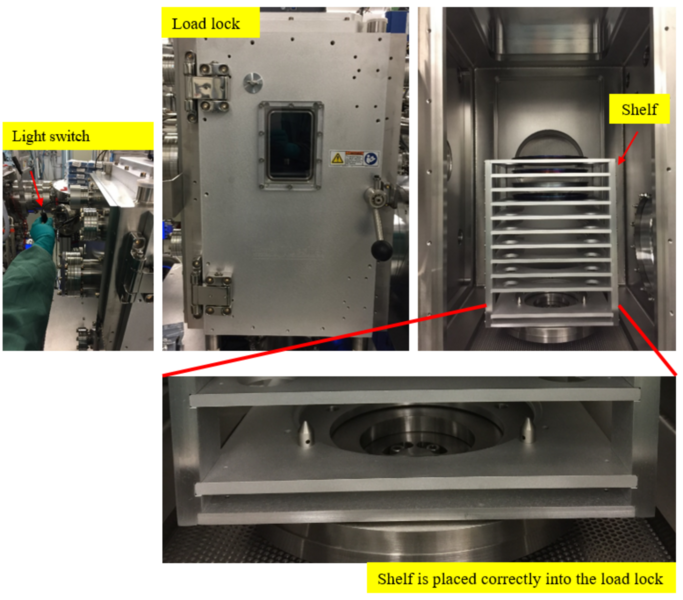

Load-lock

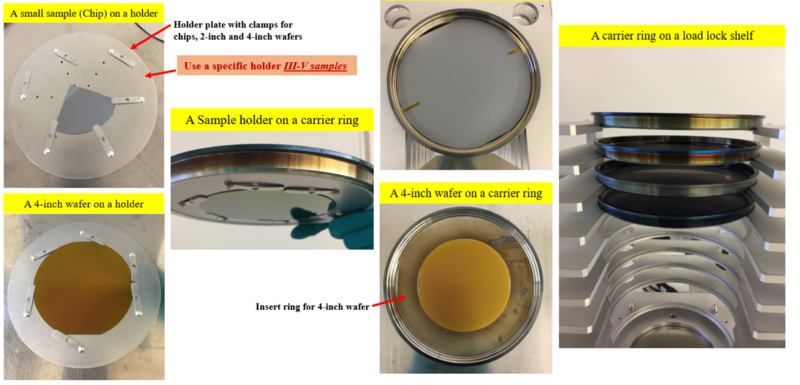

The load lock chamber is the only part of the tool which can be accesed by users. Ventilation and pumping takes approximately 5 min. The chamber has its own turbo pump. Inside there is a shelf - a cassette with 10 slots. The images below show the load lock set-up and sample mounting. The shelf is designed to handle 6-inch wafers, which have to be placed on dedicated carrier rings. The rings with wafers can be introduced onto the cassette shelf. Different adapters can be used for 4-inch wafers and small chips. After the load lock is pumped it takes approx. 6 min to transfer the sample into the process chamber and 8 min to return.

- Cassette loader and sample mounling.

-

The load lock chamber.

-

Sample holder, carrier ring and load lock shelf.

Attention! The shelf turns to the opposite side from where the carrier ring is loaded- Furthermore, the shelf has to be placed properly inside the load lock. A carrier ring without a sample must never be loaded in the load lock. The light in the load lock chamber can be turned on. The light switch is located on the left side of the load-lock. Process chambers PC 1 and PC 3 are also equipped with light switches.

Process information

Too high sputter power can cause target or sputter gun damage. Given the target/interface thermal limitations, such damage can be reduced/eliminated by using an appropriate maximum power. However, "appropriate" often equates to "low" and low power means low deposition rate. Once the appropriate power has been established for a given target/gun, never switch on and immediate increase power to that value! Always increase power slowly to its maximum value through a series of ramps. When the deposition run is complete, it is equally important to ramp down power at the same rate as ramp up, allowing the target to cool slowly to avoid thermal shock and the potential for target fracture.

The table below shows the maximum power and maximum ramp up/down power for available materials:

| Target size | Target material | Maximum Power density (W/inch2) | Maximum Power (W) | Maximum Ramp up/down Power (W/s) | Comments

|

|---|---|---|---|---|---|

| 3 inch | Al | 150 | 1000 | 10 | DC/HiPIMS |

| Au (Bonded) | 20 | 140 | 0.3 | DC/HiPIMS | |

| Ag | 100 | 700 | 10 | DC/HiPIMS | |

| Cu | 200 | 1400 | 10 | DC/HiPIMS | |

| Ni | 50 | 350 | 10 | High Strengh Magnets /DC | |

| Ti | 50 | 350 | 10 | DC/HiPIMS | |

| Ge (Bonded) | 20 | 140 | 0.3 | DC/RF | |

| Si (Unbonded/Bonded) | 20 | 140 | 0.3 | RF

| |

| SiO2 (Bonded) | 20 | 140 | 0.3 | RF

| |

| ITO (Bonded) | 20 | 140 | 0.3 | PDC

| |

| BaTiO3 (Bonded) | 20 | 140 | 0.3 | RF

| |

| NbTi | 50 | 350 | 10 | DC | |

| 4 inch | Al | 150 | 1800 | 10 | DC/HiPIMS |

Additional information about the processes and equipment performace can be found here:

- Pre-acceptance test File:Cluster-based multi-chamber high vacuum sputtering deposition system pre acceptance.pptx

Standard recipe performance

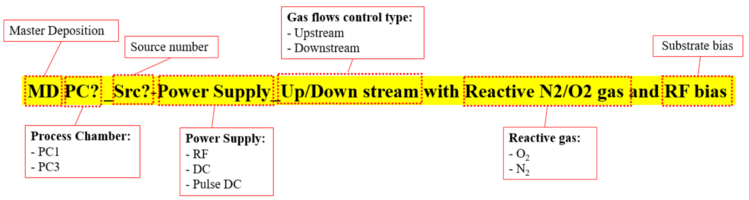

There are 76 developed and tested process recipes for general users (48 for PC1 and 28 for PC3). They include non-reactive and reactive DC, RF and PulseDC sputtering with or without substrate bias. Deposition using HiPIMS can only be done with DTU Nanolab staff assistance. Starting the recipe the user can change the relevant process parameters: power, pressure, reactive gas ratio, rotation speed, substrate bias, etc. Each of the 76 recipes has a unique name which indicates the process chamber, type of sputtering (DC, RF, or Pulse DC), gas flow control, the type of reactive gas and the presence of substrate bias. In addition to the standard process recipes, there are also recipes for substrate heating and RF cleaning.

- The build-up of the standard recipe name

-

The standard recipe has its own unique name starting with the letters "MD" which stands for "Master Deposition".

So far the following results can be used as a guide or reference:

(Look for updated information in a specific material list).

| Recipe name | Target material | Pressure (mTorr) | Power (W) | Deposition rate (nm/min) | Uniformity (%) on 6 inch wafer |

Comments

|

|---|---|---|---|---|---|---|

| MD PC1 Src1 RF Upstream | SiO2 | 3 | 140 (RF) | 2.3 | 0.5 | |

| MD PC1 Src2 RF Upstream | SiO2 | 3 | 140 (RF) | 2.6 | 3 | |

| MD PC1 Src3 DC Upstream | Ni | 3 | 500 (DC) | 23.3 | 2.5 | |

| MD PC1 Src4 DC Upstream | Cu | 3 | 500 (DC) | 52.2 | 2.2 | |

| MD PC1 Src5 DC Upstream | Al | 3 | 200 (DC) | 7.9 | 3.2 | |

| MD PC1 Src5 Pulse DC Downstream with reactive O2 |

Al | 3 | 500 (PDC) Frequency: 100Hz Reverse time: 2µs |

1.7 | 3.4 | Ar flow: 50sccm O2 flow: 15 sccm

|

| MD PC1 Src6 Pulse DC Upstream | ITO | 3 | 140 (PDC) Frequency: 100Hz Reverse time: 2µs |

11 | 4.5 | |

| MD PC1 Src6 Pulse DC Downstream with reactive O2 |

ITO | 3 | 140 (PDC) Frequency: 100Hz Reverse time: 2µs |

11.3 | - | Ar flow: 50sccm O2 flow: 2 sccm |

| MD PC1 Src1 RF Upstream | Si | 3 | 120 (RF) | 1.8 | - | |

| MD PC3 Src1 Pulse DC Downstream with reactive N2 |

Al | 3 | 900 (PDC) Frequency: 100Hz Reverse time: 2µs |

29 | 3.2 | Ar flow: 50sccm O2 flow: 15 sccm |

Substrate heating

During the test by KJLC, using a wafer with thermocouples attached to it, the temperature of the wafer and the control thermocouple could be tracked. In general, the sample will be about 50 degrees less than the temperature displayed on the system. There are software interlocks that control/protect the heater as well as a hardware interlock that will prevent the heater from turning on when the chamber is at atmosphere or if there is insufficient water flow on the system.

There are software interlocks that will not allow the transfer port to open while the heater is on. Also, it will not allow the heater to turn on if there is no assigned wafer in the chamber, and will not allow the chamber vent valve to open if the temperature shows above 80 °C.

There is no sensor to detect if a sample is physically present. If a user transfers an empty wafer carrier into a process chamber, the wafer ID will move accordingly and the heater can be turned on.

A sample transfer can be done while the sample is hot but not while the heater is on. The heater thermocouples will cool very rapidly as soon as the heater is turned off so there is no set temperature. A sample transfer unload should be done when the temperature is below 300 °C.

There are dedicated recipes to turn on a heater:

- If PC1 is used, select “Master Heater PC1 - On”

- If PC3 is used, select “Master Heater PC3 - On”

Substrate cleaning (RF Bias)

RF cleaning can be used to clean the sample before the deposition. There are dedicated recipes for that:

- If PC1 is used, select “Master Bias PC1_Upstream”

- If PC3 is used, select “Master Bias PC3_Upstream”

The user can select rotation speed (10 rpm), process pressure (1-15mTorr) RF power (maximum 100 W) and cleaning time (maximum 1800 s).

Batch process

The advanced system with the cassette loader and robot arm allow running a batch process ("Master Cassette" recipes). These processes are not among the standard recipes but can be developed by DTU Nanolab upon request.