Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano10: Difference between revisions

Appearance

| Line 44: | Line 44: | ||

C4F8 52 sccm, SF6 38 sccm, 4 mTorr, Strike 3 secs @ 15 mTorr, 800 W CP, 50 W PP, 10 degs, 120 secs | C4F8 52 sccm, SF6 38 sccm, 4 mTorr, Strike 3 secs @ 15 mTorr, 800 W CP, 50 W PP, 10 degs, 120 secs | ||

</gallery> | </gallery> | ||

== Comments == | |||

The process looks to be too etch aggressive, not enough passivation. I would consider any or all of the following: | |||

* Decreasing the wafer temperature (make more passivant) | |||

* Increasing C4F8 flow (make more passivant) | |||

* Increasing platen power (make more directional) | |||

* Decreasing coil power (make less etch-aggressive and more directional. | |||

Also, if the tool has Short Funnel and 5mm spacers fitted, it may be too close to the plasma - previous good nano-scale etch result was achieved with Long Funnel and 100mm spacers. | |||

The conditions are similar to the nano-etch conditions for acceptance process C: | |||

{| border="2" cellpadding="2" cellspacing="1" | |||

|- | |||

| | |||

| Etch | |||

|- | |||

| Gas Flow (sccm) | |||

| SF<sub>6</sub> 38 + C<sub>4</sub>F<sub>8</sub> 70 | |||

|- | |||

| Pressure (mT) | |||

| 4 | |||

|- | |||

| APC angle (%) | |||

| 33.2 | |||

|- | |||

| Coil power (W) | |||

| 450 | |||

|- | |||

| Matching (Forward/ Load) | |||

| L/ 33 & T/ 43 | |||

|- | |||

| HF Platen power (W) | |||

| 100 | |||

|- | |||

| Matching (Forward/ Load) | |||

| L/ 49 & T/ 53 | |||

|- | |||

| Time | |||

| 01:30 | |||

|- | |||

|} | |||

Revision as of 08:38, 31 March 2011

The nano1.0 recipe

| Recipe | Gas | C4F8 38 sccm, SF6 52 sccm |

|---|---|---|

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | |

| Power | 800 W CP, 50 W PP | |

| Temperature | 10 degs | |

| Hardware | 100 mm Spacers | |

| Time | 120 secs | |

| Conditions | Run ID | 1801 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

| Mask | 1dfhj10 nm zep etched down to 6dgh4 nm |

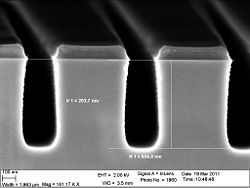

- The results of the nano1.0 recipe

-

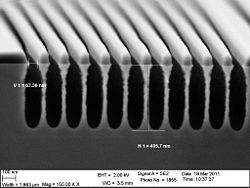

The 30 nm trenches

-

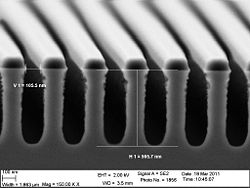

The 60 nm trenches

-

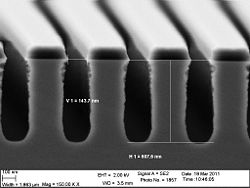

The 90 nm trenches

-

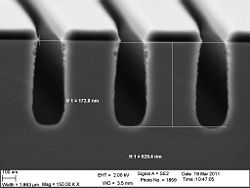

The 120 nm trenches

-

The 150 nm trenches

Comments

The process looks to be too etch aggressive, not enough passivation. I would consider any or all of the following:

- Decreasing the wafer temperature (make more passivant)

- Increasing C4F8 flow (make more passivant)

- Increasing platen power (make more directional)

- Decreasing coil power (make less etch-aggressive and more directional.

Also, if the tool has Short Funnel and 5mm spacers fitted, it may be too close to the plasma - previous good nano-scale etch result was achieved with Long Funnel and 100mm spacers.

The conditions are similar to the nano-etch conditions for acceptance process C:

| Etch | |

| Gas Flow (sccm) | SF6 38 + C4F8 70 |

| Pressure (mT) | 4 |

| APC angle (%) | 33.2 |

| Coil power (W) | 450 |

| Matching (Forward/ Load) | L/ 33 & T/ 43 |

| HF Platen power (W) | 100 |

| Matching (Forward/ Load) | L/ 49 & T/ 53 |

| Time | 01:30 |