Specific Process Knowledge/Lithography/DUVStepperLithography: Difference between revisions

No edit summary |

|||

| Line 293: | Line 293: | ||

<br clear="all" /> | <br clear="all" /> | ||

{{:Specific Process Knowledge/Lithography/Development/DUV_developer}} | |||

Development | |||

Revision as of 10:53, 30 January 2023

DUV Stepper

Feedback to this section: click here

The deep-UV stepper FPA-3000EX4 from Canon is an advanced exposure system designed for mass-production of 6 and 8 inch wafers/ devices having a throughput of up to 90 wafers per hour. The largest applicable thickness of the wafers/ devices is 1,2 mm. Also 4" wafers/ devices can be processed with some restrictions concerning throughput, resolution, uniformity and maximum allowed wafer thickness. The system is equipped with a KrF Excimer laser from Cymer (wavelength 248 nm). Its projection lens’ NA is variable over a range between 0,4 and 0,6. Additionally, the partial coherence factor (σ) of the illumination system can be adjusted and different off-axis illumination modes can be selected.

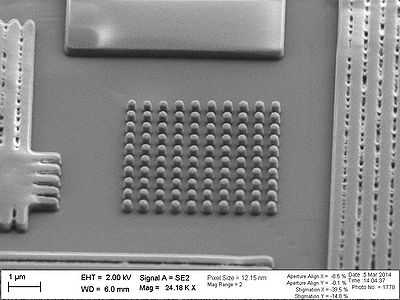

The critical dimension (CD) of patterns that can be realized is specified at around 250nm for arbitrary formed patterns in the standard illumination mode (NA=0,6; σ =0,65). However, the best achievable resolution is different for each pattern type, pattern shape and pitch. So linewidths down to 160 nm could be achieved for geometrically simple patterns or pattern arrays (single and multiple line or pin-hole structures).

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:

Equipment info in LabManager

Process information

| Purpose |

Exposure system designed for mass/production of devices with linewidth down to 250nm | ||

|---|---|---|---|

| Specifications | Magnification |

1:5 | |

| Projection lens Numerical Aperture |

0,4 - 0,60 | ||

| Illumination system's σ |

0,2 - 0,75 (standard illumination mode: σ = 0,65) | ||

| Exposure source |

KrF laser | ||

| Wavelength |

248nm | ||

| Illumination intensity |

2800 W/m2 | ||

| Illumination uniformity |

1,2% | ||

| Maximum printed field size |

22 x 26 mm (maximum on wafer) | ||

| Alignment accuracy |

3 sigma = 50 nm | ||

| Substrates | Substrate size |

| |

| Allowed materials |

| ||

| Batch |

1 - 25 | ||

Spin coater: Süss stepper

Feedback to this section: click here

This spinner is dedicated for spinning DUV resists. The spinner is fully automatic and can run up to 25 substrates in a batch 4", 6", and 8" size (8" requires tool change). The machine is equipped with the 3 resist lines (DUV42S-6, KRF M230Y, and KRF M35G), an automatic syringe system and a solvent line for cleaning and back-side rinse.

The user manual, quality control procedures and results, user APVs, and contact information can be found in LabManager: Equipment info in LabManager

DUV resist overview

The spinning process will be performed by the customer together with the Photolith group of Nanolab. In case you would like to do DUV lithography, please contact Lithography team, who will consult you and run your wafers together with you.

Bottom Anti Reflection Coating (BARC):

Positive DUV resist for spin coating in 600-300nm thickness range:

Positive DUV resist for spin coating in 1600-800nm thickness range:

Negative DUV resist for spin coating in 1400-800nm or diluted with EC Solvent in 1:1 in 400-200nm thickness range:

- Manufacturers website: UVN2300-0.8

- Datasheet: UVN2300-0.8 - requires login

Quality Control (QC)

THIS SECTION IS UNDER CONSTRUCTION

| Quality Control (QC) for Spin coater: Süss Stepper - BARC DUV42S-6 | ||||||||||||||||||||||||

Spin-off speed will be adjusted if film thickness is outside the limit. |

| Quality Control (QC) for Spin coater: Süss Stepper - BARC DUV42S-6 | ||||||||||||||||||||||||

Spin-off speed will be adjusted if film thickness is outside the limit. |

Standard processes

BARC DUV42S-6 coating sequences:

- (1201) DCH 150mm BARC 65nm Dispense 3ml@1000rpm; spin-off 30s@4700rpm; softbake 60s@175°C

- (1202) DCH 100mm BARC 65nm Dispense 1.6ml@1000rpm; spin-off 30s@3000rpm; softbake 60s@175°C

KRF M230Y coating sequences:

- (1301) DCH 150mm M230Y 360nm Dispense 3ml@1000rpm; spin-off 30s@2500rpm; softbake 90s@130°C

- (1302) DCH 100mm M230Y 360nm Dispense 1ml@1000rpm; spin-off 30s@2500rpm; softbake 90s@130°C

KRF M35G coating sequences:

- (1401) DCH 150mm M35G 750nm Dispense 3ml@1000rpm; spin-off 60s@5000rpm; softbake 90s@130°C

- (1402) DCH 100mm M35G 750nm Dispense 1ml@1000rpm; spin-off 60s@5000rpm; softbake 90s@130°C

- (1403) DCH 150mm M35G 1000nm Dispense 3ml@1000rpm; spin-off 60s@2630rpm; softbake 90s@130°C

- (1404) DCH 100mm M35G 1000nm Dispense 1ml@1000rpm; spin-off 60s@2630rpm; softbake 90s@130°C

- (1405) DCH 150mm M35G 1400nm Dispense 3ml@1000rpm; spin-off 60s@1310rpm; softbake 90s@130°C

- (1406) DCH 100mm M35G 1400nm Dispense 1ml@1000rpm; spin-off 60s@1310rpm; softbake 90s@130°C

| Purpose |

| ||

|---|---|---|---|

| Resist |

| ||

| Performance | Coating thickness |

| |

| Process parameters | Spin speed |

10 - 5000 rpm | |

| Spin acceleration |

100 - 10000 rpm/s | ||

| Hotplate temperature |

| ||

| Substrates | Substrate size |

| |

| Allowed materials |

| ||

| Batch |

1 - 25 | ||

Developer: TMAH Stepper

This developer is dedicated for development of DUV resists. The developer is fully automatic and can run up to 25 substrates in a batch 4", 6", and 8" size (8" requires tool change). The machine is equipped with 1 developer line, in our case 2,38% TMAH in water (AZ 726 MIF), 1 topside rinse line with water, 1 backside rinse line with water and 1 N2 line for drying.

The user manual and contact information can be found in LabManager - requires login

Process information

The development process will be performed by the customer together with the Photolith group of DTU Nanolab. In case you would like to do DUV lithography please contact Lithography team, who will consult you and run your wafers together with you.

Here you can find a chart demonstrating a dependence between 250 nm line width/pillars diameter and exposure dose.

Standard processes

Post-exposure bake sequences:

- (1000) DCH PEB 130C 60s 60s baking at 130°C; 20s cooling

- (1001) DCH PEB 130C 90s 90s baking at 130°C; 20s cooling

Development sequences:

- (1004) DCH DEV 60s 60s single puddle development

Combined PEB and development sequences:

- (1002) DCH PEB_60s and DEV_60s 60s baking at 130°C followed by 60s single puddle development

- (1003) DCH PEB_90s and DEV_60s 90s baking at 130°C followed by 60s single puddle development

The standard developer process consists of:

- pre-wetting with water (2.5s @ 1000rpm)

- developer dispense (2.5s @ 40rpm, corresponding to ~9ml)

- development (60s @ 0rpm)

- water rinse with BSR (5s @ 3000rpm)

- nitrogen drying (7s @ 4000rpm)

and has a cycle time of ~2 minutes

| Purpose |

Development of DUV resist: KRF M230Y and KRF M35G | ||

|---|---|---|---|

| Developer |

2,38% water based TMAH | ||

| Process parameters | Spin speed |

10 - 5000 rpm | |

| Spin acceleration |

100 - 10000 rpm/s | ||

| Hotplate temperature |

130°C for post exposure baking | ||

| Substrates | Substrate size |

| |

| Allowed materials |

| ||

| Batch |

1 - 25 | ||