Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-2: Difference between revisions

| Line 19: | Line 19: | ||

Click [[Specific Process Knowledge/DRIE-Pegasus/Pegasus-2/OldConfig | '''here''']] to access older configurations. | Click [[Specific Process Knowledge/DRIE-Pegasus/Pegasus-2/OldConfig | '''here''']] to access older configurations. | ||

The current configuration is | The current configuration is set up for nanoscale etching. | ||

{{Template:Peg2configheader1 | {{Template:Peg2configheader1 | ||

| Line 46: | Line 46: | ||

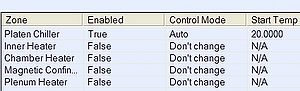

|ItemComment= The temperature on the heaters in the plasma source are set to 20 degrees with a high tolerance. This essentially corresponds to powered off compared to default Pegasus temperatures which are in the 120-140 degrees range. | |ItemComment= The temperature on the heaters in the plasma source are set to 20 degrees with a high tolerance. This essentially corresponds to powered off compared to default Pegasus temperatures which are in the 120-140 degrees range. | ||

Always make sure that the temperature settings in the recipes are not enabled | Always make sure that the temperature settings in the recipes are ''not'' enabled. Click [[Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-2/TemperatureSettings |'''here''']] to have more information. | ||

}} | }} | ||

{{Template:Peg2configcontent1 | {{Template:Peg2configcontent1 | ||

Revision as of 15:32, 15 December 2020

Feedback to this page: click here

Restrictions on a dedicated research tool

In general, the dry etch tools at DTU Nanolab are free to use for users with proper training. The users have freedom to etch the approved materials and substrates within rules specified in manuals, LabAdviser and cross contamination sheets. At the same time, the instruments are set up to meet the broadest range of etch demands in this way ensuring that most dry etch applications can be covered. For most of the instruments, however, there is a continuous tug of war between providing flexibility (for instance allowing mask materials that do not form any volatile etch products with the gas chemistry available in the process chamber) while ensuring process chamber cleanliness.

Pegasus 2 is a dedicated research tool where the research group of professor Henri Jansen [1] has freedom to explore the conventions of dry etching. This requires that a very strict control be applied to the process chamber in terms of the range of processes and substrates used. As such, the instrument will not be released for general use for a wide range of applications.

If you want to get access to the tool, then talk to professor Henry Jansen

Current setup and rules on Pegasus 2

Click here to access older configurations.

The current configuration is set up for nanoscale etching.

| Item | The currently applied modification | Comments |

|---|---|---|

| Available gasses and gas chemistry | Available gasses:

Not available:

|

OnlySF6 and O2 are used for Si, PR, and Cr etch. The rest is only make-up |

| Plasma source heaters | Applies to

|

The temperature on the heaters in the plasma source are set to 20 degrees with a high tolerance. This essentially corresponds to powered off compared to default Pegasus temperatures which are in the 120-140 degrees range.

Always make sure that the temperature settings in the recipes are not enabled. Click here to have more information. |

| RF power and pressure settings | All recipes run without coil power, very low platen power and low pressures | None of the recipes use coil power in order to prevent aluminium fluoride formation at the aluminium oxide dome. These particles may drop on the wafer or chuck and cause abnormalitites.

Most of the recipes rely on very low pressure and low power - 0.2 mTorr and 10 Watt platen power is not an error and easily supports the plasma. |

| Carbon free plasmas | The process chamber does not have any carbon containing etch gasses. Therefore, polymer build-up on the chamber walls is not an issue. The 'carbon free' policy does not, however, apply to the choice of masking materials and CSAR, AZ and DUV resists are allowed. | |

| Chamber conditioning and cleaning | Running long oxygen cleans is not necessary and must be avoided. Neither are shorter cleans between wafers. | The absence of carbon containing etch gasses ensures that the process chamber is kept clean. |

| Approved recipes | Running long oxygen cleans is not necessary and must be avoided. Neither are shorter cleans between wafers. | The absence of carbon containing etch gasses ensures that the process chamber is kept clean. |

Access to Pegasus 2 configuration templates

Pegasus 2 configuration table version 1

- Table header: Template:Peg2configheader1

- Table content: Template:Peg2configcontent1