Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-2/Si Nano etching: Difference between revisions

Appearance

No edit summary |

No edit summary |

||

| Line 4: | Line 4: | ||

Below are images illustrating works that have been done during the ph.d. projects. | Below are images illustrating works that have been done during the ph.d. projects. | ||

<gallery caption="" widths="380px" heights="300px" perrow="3"> | <gallery caption="" widths="380px" heights="300px" perrow="3"> | ||

image: | image:3D.png| 1. 3D silicon photonic crystal membranes. | ||

image:Scallops.png| 2. Comparison of scallops by traditional Bosch process and modified DREM process. | image:Scallops.png| 2. Comparison of scallops by traditional Bosch process and modified DREM process. | ||

image:3Dmicro.png| 3. 3D silicon microstructures fabricated by DREM process. | image:3Dmicro.png| 3. 3D silicon microstructures fabricated by DREM process. | ||

Revision as of 13:13, 10 May 2020

Feedback to this page: click here

Below are images illustrating works that have been done during the ph.d. projects.

-

1. 3D silicon photonic crystal membranes.

-

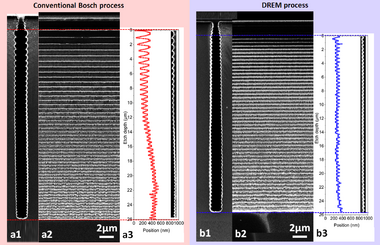

2. Comparison of scallops by traditional Bosch process and modified DREM process.

-

3. 3D silicon microstructures fabricated by DREM process.

-

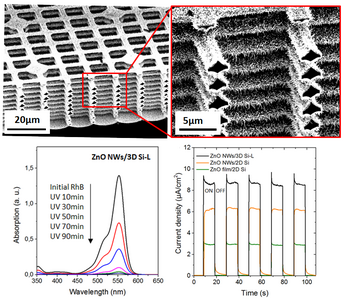

4. 3D silicon micro-mesh structures integrated with ZnO nanowires for photocatalysis and photocurrent generation.

-

5. 3D silicon stacked nanowires for structural color generation.

-

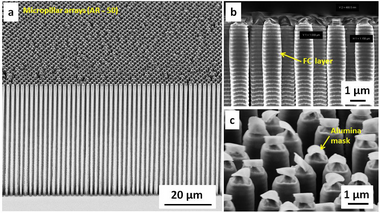

6. High aspect ratio silicon micropillars fabricated with DREM process.

-

7. ZIF-8 crystals for tunable structural colors.

-

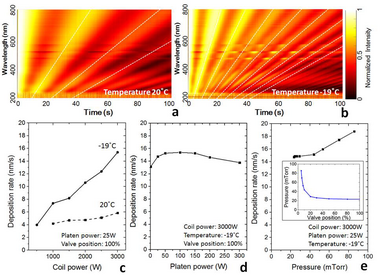

8. Using OES to monitor the fluorocarbon film deposition with Pegasus 1.