Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4: Difference between revisions

| Line 49: | Line 49: | ||

<!-- *[[Specific Process Knowledge/Etch/DRIE-Pegasus/VeeryDeeep| Very deep etching]] --> | <!-- *[[Specific Process Knowledge/Etch/DRIE-Pegasus/VeeryDeeep| Very deep etching]] --> | ||

=== Wafer bonding === | === Wafer bonding === | ||

Revision as of 16:04, 16 November 2020

Feedback to this page: click here

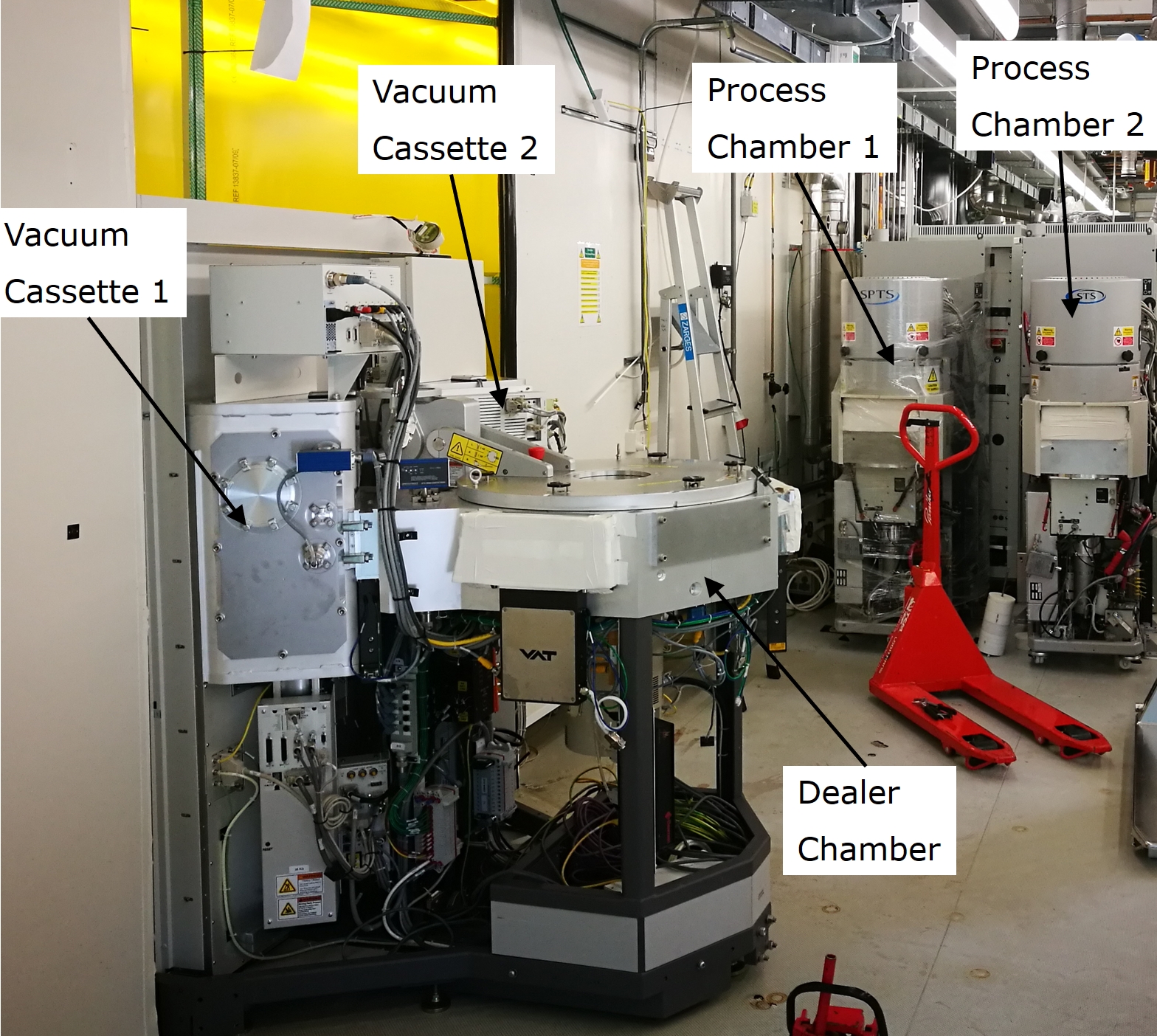

Pegasus 4 - 150mm silicon oxide and silicon nitride etching

The tool is already installed and ready to process. The picoscope, the chamber are working well right now but we still have some troubles with the wafers aligner in the loadlock.

The user manual(s), quality control procedure(s) and results, user APV(s) are not available, technical information and contact information can be found in LabManager:

Equipment info in LabManager

Process information

Hardware changes

A few hardware modifications have been made on the Pegasus 3/4 since it was installed in 2019. The changes are listed below.

Other etch processes

More processes, such as for DUV resist, are currently being developed, but they are not quite 'ready for publication' at LabAdviser so please contact Jonas (mailto:jmli@dtu.dk) for more information.

Wafer bonding

To find information on how to bond wafers or chips to a carrier wafer, click here.

Acceptance test

The instrument was opened for users in April 2010 when the acceptance test was signed. This was based on the performance of five standard recipes (A, B, C, D and SOI) that are further examined below. The acceptance test report is found here.

Characterisation of etched trenches

Comparing differences in etched trenches requires a set of common parameters for each trench. Click HERE to find more information about the parameters used on the DRIE-Pegasus process development.

Internal Nanolab Process log for Pegasus 1

Process log at Nanolab [1]