Specific Process Knowledge/Etch/DRIE-Pegasus/picoscope: Difference between revisions

Appearance

| Line 42: | Line 42: | ||

<gallery caption="4 cycles of Process A " widths="400" heights="500" perrow="2"> | <gallery caption="4 cycles of Process A <span id="anchor_name">some text</span>" widths="400" heights="500" perrow="2"> | ||

image:Process A SPTS.png | Left: Recorded with the SPTS software | image:Process A SPTS.png | Left: Recorded with the SPTS software | ||

image:Process A pico.png | Right: Recorded with the Picoscope | image:Process A pico.png | Right: Recorded with the Picoscope | ||

Revision as of 14:17, 17 March 2020

Feedback to this page: click here

Process optimization using the Picoscope

The original standard recipes on Pegasus 1 differ in many ways. The second step of one of them is listed below:

| Process A Step 2 parameters | ||

|---|---|---|

| Parameter | Etch | Dep |

| Gas flow (sccm) | SF6 350 (1.5 s), 550 | C4F8 200 |

| Cycle time (secs) | 7.0 | 4.0 |

| Pressure (mtorr) | 25 (1.5 s), 150 | 25 |

| Coil power (W) | 2800 | 2000 |

| Platen power (W) | 140 (1.5) 45 | 0 |

| Common | Temperature 20 degs | |

When running any recipe on the SPTS Pro software, a set of process parameters are recorded (defined in the logging recipe that can be modified like any other recipe) as the process runs. This data can be accessed later by looking up the datalog. During the process itself, one can also activate the 'Trace' to monitor the process parameters in real time.

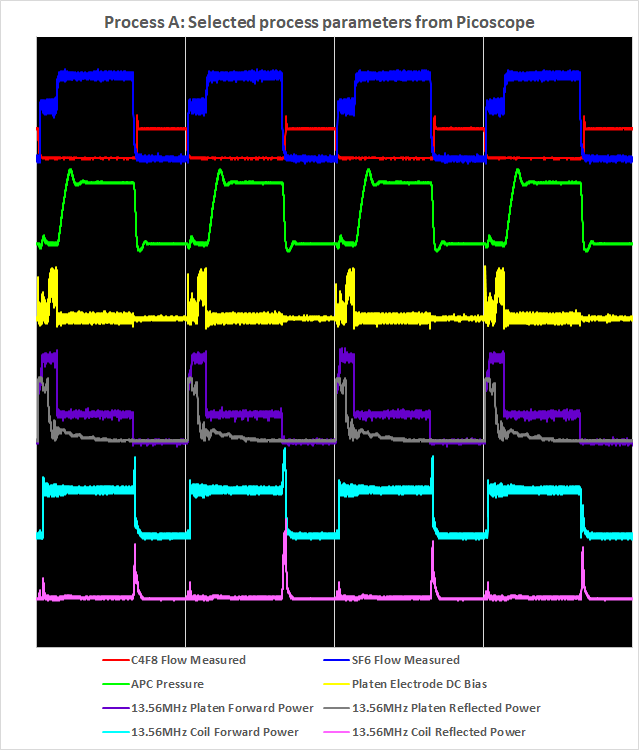

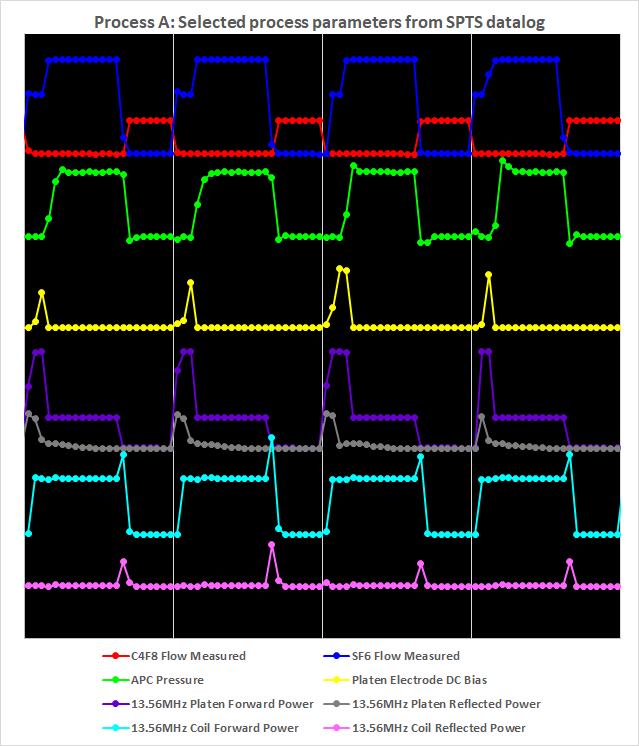

- 4 cycles of Process A <span id=

-

Left: Recorded with the SPTS software

-

Right: Recorded with the Picoscope

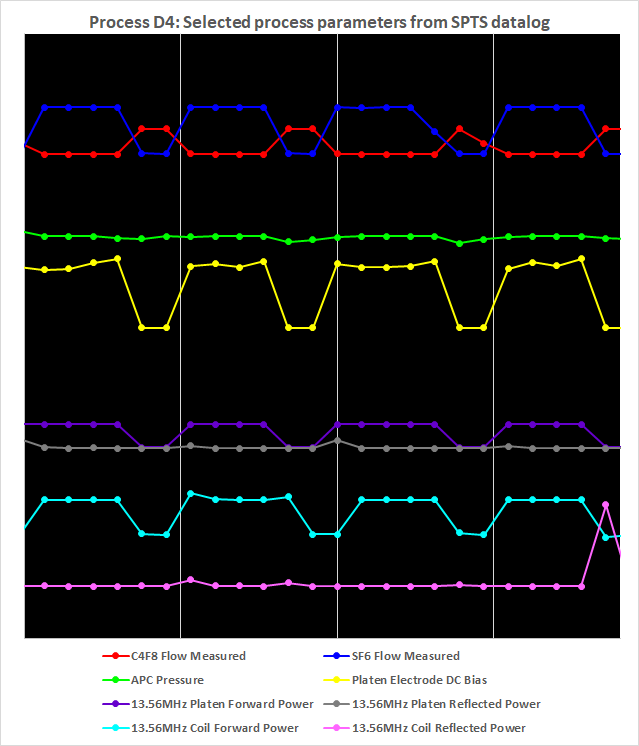

- 4 cycles of Process D4

-

Left: Recorded with the SPTS software

-

Right: Recorded with the Picoscope