Specific Process Knowledge/Characterization/AFM: Atomic Force Microscopy/AFM Icon Acceptance: Difference between revisions

| Line 3: | Line 3: | ||

=AFM Icon 1 accessories and acceptance test= | =AFM Icon 1 accessories and acceptance test= | ||

==Accessories following the system== | ==Accessories following the system== | ||

{| border="2" cellspacing="0" cellpadding="2" | |||

!colspan="2" border="none" style="background:silver; color:black;" align="center"|Equipment | |||

|style="background:WhiteSmoke; color:black"|<b>AFM Icon</b> | |||

|style="background:WhiteSmoke; color:black"|<b>AFM Icon 2</b> | |||

|- | |||

!style="background:silver; color:black;" align="left"|Position | |||

|style="background:LightGrey; color:black"| | |||

|style="background:WhiteSmoke; color:black"| | |||

Inside the cleanroom | |||

|style="background:WhiteSmoke; color:black"| | |||

In the basement of building 346 | |||

|- | |||

!style="background:silver; color:black;" align="left"|Purpose | |||

|style="background:LightGrey; color:black"|Topografic measurement in the nanometer and and sub-micrometer regime and electrical and mechanical measurements | |||

|style="background:WhiteSmoke; color:black"| | |||

*Surface roughness measurement | |||

*Step/structure hight measurement | |||

*Surface image | |||

*Surface potential | |||

*Modulus | |||

*Adhesion | |||

*Deformation | |||

|style="background:WhiteSmoke; color:black"| | |||

*Surface roughness measurement | |||

*Step/structure hight measurement | |||

*Surface image | |||

|- | |||

!style="background:silver; color:black" align="left"|Performance | |||

|style="background:LightGrey; color:black"|Scan range xy | |||

|style="background:WhiteSmoke; color:black"|Up to 90 µm square | |||

|style="background:WhiteSmoke; color:black"|Up to 90 µm square | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Scan range z | |||

|style="background:WhiteSmoke; color:black"| Up to 13µm | |||

|style="background:WhiteSmoke; color:black"| Up to 13µm | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Vertical noise floor | |||

|style="background:WhiteSmoke; color:black"|<30pm RMS | |||

|style="background:WhiteSmoke; color:black"|<30pm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|X-Y position noise (closed loop) | |||

|style="background:WhiteSmoke; color:black"|<0.15nm RMS | |||

|style="background:WhiteSmoke; color:black"|<0.15nm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Z sensor noise level(closed loop) | |||

|style="background:WhiteSmoke; color:black"|35pm RMS | |||

|style="background:WhiteSmoke; color:black"|35pm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Integral nonlinearity(X-Y-Z) | |||

|style="background:WhiteSmoke; color:black"|<0.5% | |||

|style="background:WhiteSmoke; color:black"|<0.5% | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|X-Y position noise (closed loop) | |||

|style="background:WhiteSmoke; color:black"|<0.15nm RMS | |||

|style="background:WhiteSmoke; color:black"|<0.15nm RMS | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Max. scan depth as a function of trench width W | |||

|style="background:WhiteSmoke; color:black"|~1 for our standard probe. Can be improved to about 10 with the right probe | |||

|style="background:WhiteSmoke; color:black"|~1 for our standard probe. Can be improved to about 10 with the right probe | |||

|- | |||

!style="background:silver; color:black" align="left"|Hardware settings | |||

|style="background:LightGrey; color:black"|Tip radius of curvature | |||

|style="background:WhiteSmoke; color:black"|Standard probe: <12 nm | |||

|style="background:WhiteSmoke; color:black"|Standard probe: <12 nm | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Standard ScanAsyst mode Cantilever/tip | |||

|style="background:WhiteSmoke; color:black"|[http://www.brukerafmprobes.com/p-3726-scanasyst-air.aspx ScanAsyst in Air] | |||

|style="background:WhiteSmoke; color:black"|[http://www.brukerafmprobes.com/p-3726-scanasyst-air.aspx ScanAsyst in Air] | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Standard Tapping mode Cantilevers/tips | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-Tap300Al-G.html Tap300Al-G] | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Super Sharp Si Cantilever/tip | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-SSS-NCHR.html SSS-NCHR] | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|High Aspect Ratio Cantilever/tip | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-AR5-NCHR.html AR5-NCHR] | |||

|style="background:WhiteSmoke; color:black"|[http://www.nanoandmore.com/AFM-Probe-AR5-NCHR.html AR5-NCHR] | |||

|- | |||

|style="background:silver; color:black"| | |||

|style="background:LightGrey; color:black"|Cantilevers/tips vendor | |||

|style="background:WhiteSmoke; color:black"| | |||

*[http://www.brukerafmprobes.com Bruker] | |||

*[http://www.nanoandmore.com/home.php www.nanoandmore.com] | |||

|style="background:WhiteSmoke; color:black"| | |||

*[http://www.brukerafmprobes.com Bruker] | |||

*[http://www.nanoandmore.com/home.php www.nanoandmore.com] | |||

|- | |||

|- | |||

!style="background:silver; color:black" align="left"|Substrates | |||

|style="background:LightGrey; color:black"|Substrate size | |||

|style="background:WhiteSmoke; color:black"|Up to 210mm in diameter and up to 15mm thick" | |||

|style="background:WhiteSmoke; color:black"|Up to 210mm in diameter and up to 15mm thick" | |||

|- | |||

!style="background:silver; color:black" align="left"| | |||

|style="background:LightGrey; color:black"|Motorized stage (X-Y axis) | |||

|style="background:WhiteSmoke; color:black"| | |||

*180mmx150mm inspection area | |||

*2µm repeatability, unidirectional | |||

*3µm repeatability, bidirectional | |||

|style="background:WhiteSmoke; color:black"| | |||

*180mmx150mm inspection area | |||

*2µm repeatability, unidirectional | |||

*3µm repeatability, bidirectional | |||

|- | |||

|style="background:silver; color:black"| | |||

| style="background:LightGrey; color:black"|Substrate material allowed | |||

|style="background:WhiteSmoke; color:black"|In principle all materials | |||

|style="background:WhiteSmoke; color:black"|In principle all materials | |||

|- | |||

|} | |||

<br clear="all" /> | |||

===Extra chuck=== | ===Extra chuck=== | ||

| Line 152: | Line 280: | ||

Potential image: Potential difference between grapheme and non-graphene is visible <br> | Potential image: Potential difference between grapheme and non-graphene is visible <br> | ||

Phase: Phase imaging maps the phase lag between the periodic signal driving the cantilever and the oscillations of the cantilever. Changes in phase lag often indicate changes in the properties of the sample surface. Here the structuring in the graphene is very clear | Phase: Phase imaging maps the phase lag between the periodic signal driving the cantilever and the oscillations of the cantilever. Changes in phase lag often indicate changes in the properties of the sample surface. Here the structuring in the graphene is very clear | ||

=AFM Icon 2 accessories and acceptance test= | =AFM Icon 2 accessories and acceptance test= | ||

Revision as of 09:00, 14 December 2018

Feedback to this page: click here

AFM Icon 1 accessories and acceptance test

Accessories following the system

| Equipment | AFM Icon | AFM Icon 2 | |

|---|---|---|---|

| Position |

Inside the cleanroom |

In the basement of building 346 | |

| Purpose | Topografic measurement in the nanometer and and sub-micrometer regime and electrical and mechanical measurements |

|

|

| Performance | Scan range xy | Up to 90 µm square | Up to 90 µm square |

| Scan range z | Up to 13µm | Up to 13µm | |

| Vertical noise floor | <30pm RMS | <30pm RMS | |

| X-Y position noise (closed loop) | <0.15nm RMS | <0.15nm RMS | |

| Z sensor noise level(closed loop) | 35pm RMS | 35pm RMS | |

| Integral nonlinearity(X-Y-Z) | <0.5% | <0.5% | |

| X-Y position noise (closed loop) | <0.15nm RMS | <0.15nm RMS | |

| Max. scan depth as a function of trench width W | ~1 for our standard probe. Can be improved to about 10 with the right probe | ~1 for our standard probe. Can be improved to about 10 with the right probe | |

| Hardware settings | Tip radius of curvature | Standard probe: <12 nm | Standard probe: <12 nm |

| Standard ScanAsyst mode Cantilever/tip | ScanAsyst in Air | ScanAsyst in Air | |

| Standard Tapping mode Cantilevers/tips | Tap300Al-G | Tap300Al-G | |

| Super Sharp Si Cantilever/tip | SSS-NCHR | ||

| High Aspect Ratio Cantilever/tip | AR5-NCHR | AR5-NCHR | |

| Cantilevers/tips vendor | |||

| Substrates | Substrate size | Up to 210mm in diameter and up to 15mm thick" | Up to 210mm in diameter and up to 15mm thick" |

| Motorized stage (X-Y axis) |

|

| |

| Substrate material allowed | In principle all materials | In principle all materials | |

Extra chuck

We have two chucks:

- A symmetric chuck that handles up to 210mm wafers and 15mm thick

- An asymmetric chuck that handles up to ~4" wafer (but not small pieces) - using this a whole 4" can be accessed without rotating the sample.

Holders

- Magnetic sample holder + magnetic discs + double sided tape

- Holder for vertical profile scans

Modes included

- ScanAsyst

- TappingMode (air)

- Contact Mode

- Lateral Force Microscopy

- PhaseImaging

- Lift mode

- MFM

- Force Spectroscopy

- Force volume

- EFM

- surface potential

- Torsional Resonance Mode

- Piezoresponse Microscopy

- Force spectroscopy

Extra modes:

- PeakForce KPFM package (incl extra box for high voltage PF KPFM)

- PFQNM package

- Microscope Image Registration and Overlay (MIRO) software. this is only working in the old software (before version 9.4)

Probes

Probes that followed the system (we may not have them anymore!)

| ScanAsyst mode | Tapping mode | Contact mode | PF-KPFM | |

|---|---|---|---|---|

| Generel description | Generel description | Generel description | ||

| Probes that followed the system |

|

|

|

|

Samples

- QC grid: VGRP-15M 10µm pitch and depth reference 178nm

- PF KPFM-SMPL Kelvin probe Sample: Al + Au on Si

Calibration samples for getting quantitative modulus measurements:

- PDMS-soft-1-12M: PDMS gel 2.5MPa

- PDMS-soft-2-12M: PDMS gel 3.5MPa

- PSFilm-12M: Polystyrene filem

- FSilica-12M: Fused Silica

- Sapphire-12M: Sapphire

- RS-12M: Ti roughness sample

- HOPG-12M: Highly Orientated Pyrolytic Graphite

- PS-LDPE: Harmonix training

- HOPG: Highly Oriented Pyrolytic Graphite

Acceptance tests done

Noise tests

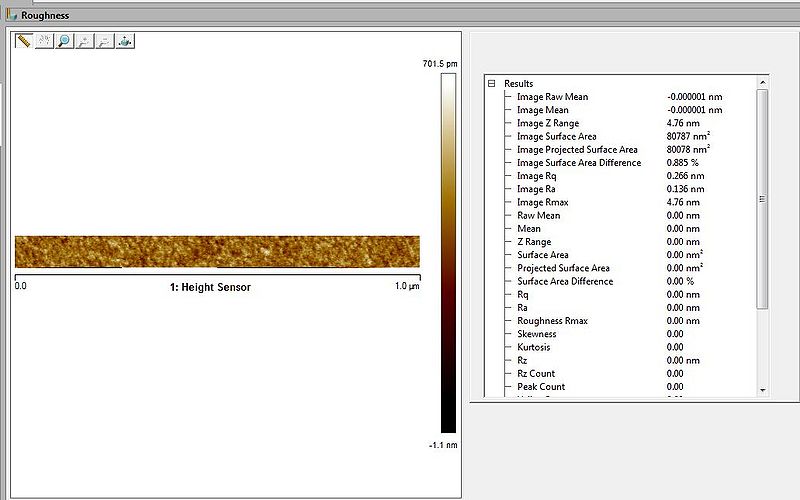

Sensor noise

Tappingmode, OTESPA-R3 probe used.

First we made a false engage (scanning in air):

Turn off gain 0 0

Z range 0.2my

Scan size 0.01nm

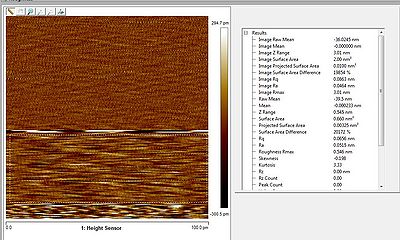

We saw some 50Hz noise (electrical - or maybe pumps): Rq 15 pm (specs 35pm)

System noise

Noise on sample: scan size 0.1nm

we started with 1my scan size to optimize the scan.

2.43Hz

256 lines

Z range at 2my to get sub nanometer resolution in Z

Rq: 54,5pm (plade vibrator koerte udenfor)

Rq: 23pm uden vibrator koerende + ro og med aaben hood.

Rq:71pm uden vibrator koerende + ro og med lukket hood

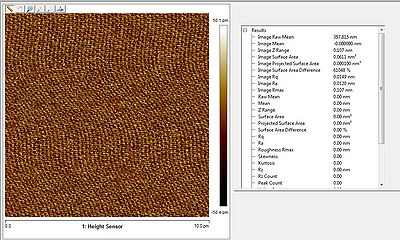

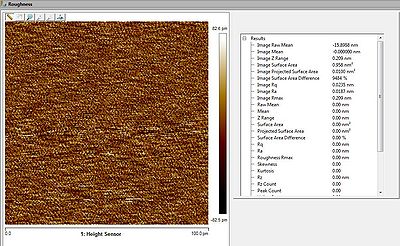

Roughness

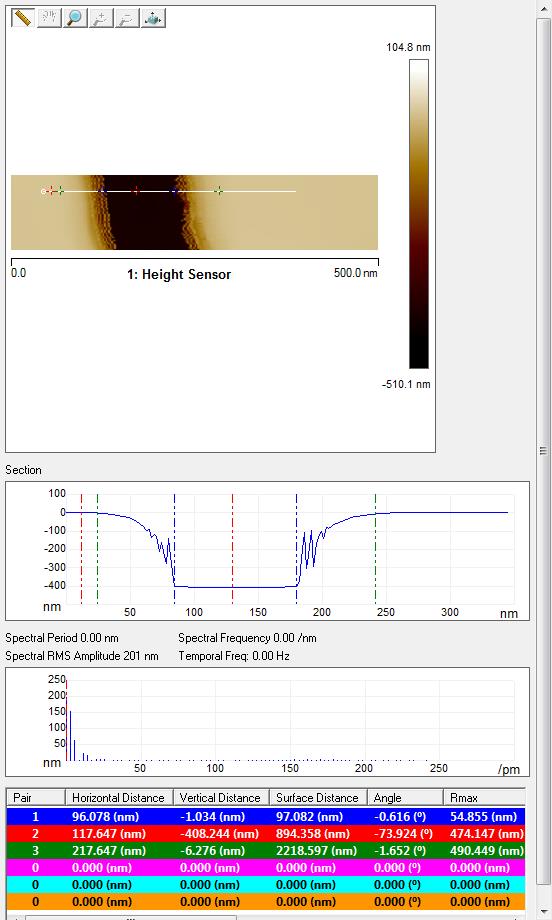

HAR: 200nm wide 400nm deep

HAR: 2µm wide 6µm deep

Graphene KPFM measurement

![]()

![]()

Height image: The graphene and structuring in graphene is not visible

Potential image: Potential difference between grapheme and non-graphene is visible

Phase: Phase imaging maps the phase lag between the periodic signal driving the cantilever and the oscillations of the cantilever. Changes in phase lag often indicate changes in the properties of the sample surface. Here the structuring in the graphene is very clear