Specific Process Knowledge/Etch/DRIE-Pegasus: Difference between revisions

| Line 58: | Line 58: | ||

! style="background:silver; color:black" | [[Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4| DRIE-Pegasus 4]] | ! style="background:silver; color:black" | [[Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4| DRIE-Pegasus 4]] | ||

|- valign="top" | |- valign="top" | ||

! | ! style="background:silver; color:black" width="120" |Purpose | ||

! style="background:WhiteSmoke; color:black" | Primary uses | ! style="background:WhiteSmoke; color:black" | Primary uses | ||

| style="background:WhiteSmoke; color:black"| Formerly the primary silicon etcher; now polymers, Silicon oxides and nitrides may also be etched. 5% metal on the surface is allowed. | | style="background:WhiteSmoke; color:black"| Formerly the primary silicon etcher; now polymers, Silicon oxides and nitrides may also be etched. 5% metal on the surface is allowed. | ||

Revision as of 14:38, 25 June 2018

Feedback to this page: click here

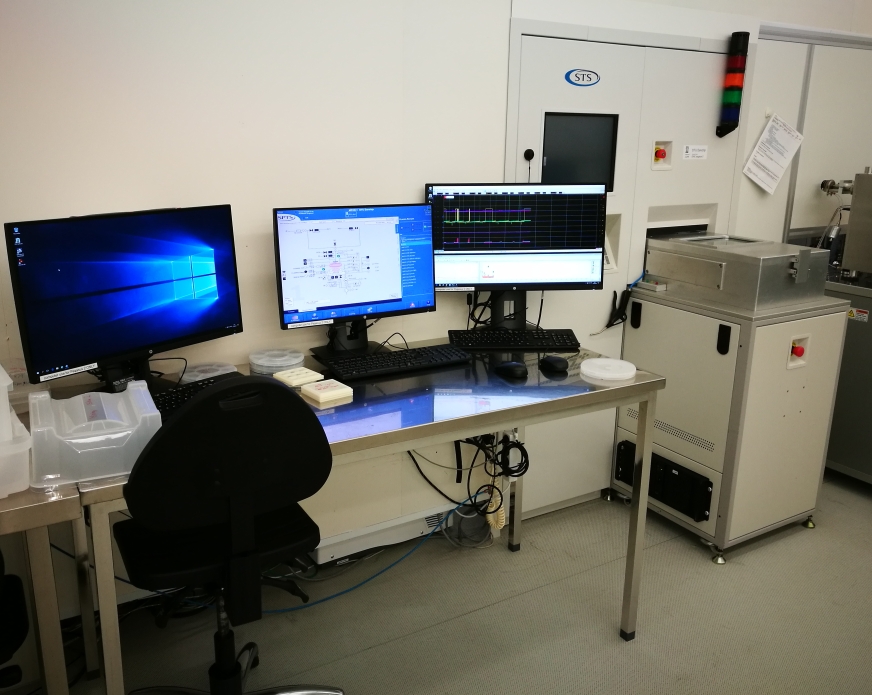

The DRIE Pegasus tools at Danchip

In 2010 Danchip acquired DRIE-Pegasus 1 (at the time called DRIE-Pegasus). As a state-of-the-art etch tool with excellent performance and great flexibility, it grew immensely popular and by 2015 it was apparent that we needed yet another tool to cope with the demand. Therefore, in 2016 Pegasus 2 was acquired from a closed-down lab in Morocco and installed next to Pegasus 1.

Then, in 2017 we got our hands on a twin Pegasus system with cassette to cassette vacuum robot at a very reasonable price from a commerciel fab. The twin Pegasus system (will be called Pegasus 3 and 4) will be installed at the old cluster 2 location in cleanroom C1 from August 2018 onwards.

The Bosch process

The DRIE Pegasus tools are state-of-art silicon dry etchers that offer outstanding performance in terms of etch rate, uniformity etc. They use the so-called Bosch process to achieve excellent control of the etched features. Click HERE for more fundamental information of the system. As of 2017, completing the Dry Etch TPT course is mandatory for all new users. On the TPT web page you will find a version of the latest lecture slides - here you will find information as well.

Links to the individual pages for the Pegasi

- DRIE-Pegasus 1

- DRIE-Pegasus 2

- DRIE-Pegasus 3 - installation in progress

- DRIE-Pegasus 4 - installation in progress

Process information

SPTS process notation

Describing a process recipe on the Pegasus may sometimes be difficult because of the great flexibility of the instrument. A compact and precise notation is therefore required for the recipes. Click HERE to find a short description of the official SPTS notation.

Hardware changes

A few hardware modifications have been made on the Pegasus since it was installed in 2010. The changes are listed below.

| DRIE-Pegasus 1 | DRIE-Pegasus 2 | DRIE-Pegasus 3 | DRIE-Pegasus 4 | ||||

|---|---|---|---|---|---|---|---|

| Purpose | Primary uses | Formerly the primary silicon etcher; now polymers, Silicon oxides and nitrides may also be etched. 5% metal on the surface is allowed. | Etching of silicon oxides or nitrides | Silicon etching | Standard recipes for etching of Al, Cr and Ti, now also etches of W, TiW and Mo | Etching of silicon oxide, resist, BCB, silicon nitride, InP, InGaAs and GaAs on III-V substrates | Etching of III-V materials such as GaN, InP/InGaAsP/InGaAs, AlGaAs, GaAs |

| Alternative/backup uses | Backup silicon etcher | Barc etch | Silicon etcher | ||||

| General description | Plasma source | Inductively coupled plasma chamber with two RF generators; the coil and platen generator | Inductively coupled plasma chamber with two RF generators; the coil and platen generator | Inductively coupled plasma chamber with two RF generators; the coil (with outer and inner coil) and platen generator | Inductively coupled plasma chamber with two RF generators; the coil and platen generator | Parallel plate capacitor setup with RF power between the two electrodes | Inductively coupled plasma chamber with two RF generators; the coil and platen generator

|

| Substrate cooling/temperature | The electrode is oil cooled. Also, Helium backside cooling: -10oC to 20oC | The electrode is oil cooled. Also, Helium backside cooling: -10oC to 60oC | The electrode is oil cooled. Also, Helium backside cooling: -20oC to 30oC | The electrode is oil cooled. Also, Helium backside cooling: -10oC to 50oC | The electrode is oil cooled: Fixed at 20oC | The electrode is oil cooled with a special chiller. Also, Helium backside cooling: 20oC to 180oC | |

| Clamping | Electrostatic clamping (semco electrode) | Electrostatic clamping (TDESC) | Electrostatic clamping (TDESC) | Electrostatic clamping (TDESC) | No clamping | Mechanical clamping (weighted clamp with ceramic fingers)

|

|- |}

General Pegasus information

Wafer bonding

To find information on how to bond wafers or chips to a carrier wafer, click here.

Characterisation of etched trenches

Comparing differences in etched trenches requires a set of common parameters for each trench. Click here to find more information about the parameters used on the DRIE-Pegasus process development.

Material from SPTS