Specific Process Knowledge/Characterization/AFM: Atomic Force Microscopy/Workspaces: Difference between revisions

Appearance

| Line 89: | Line 89: | ||

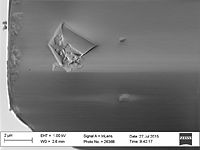

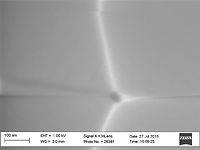

|Box1 no. 8||mattod||Bad force curve||[[File:Box1 no8 tilt0_30.jpg|200px]][[File:Box1 no8 tilt0_31.jpg|200px]] | |Box1 no. 8||mattod||Bad force curve||[[File:Box1 no8 tilt0_30.jpg|200px]][[File:Box1 no8 tilt0_31.jpg|200px]] | ||

|- | |- | ||

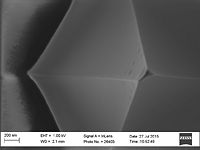

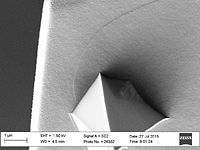

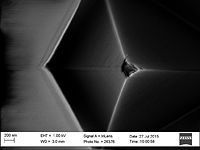

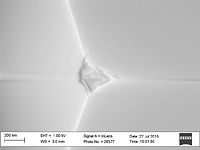

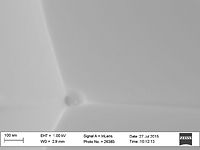

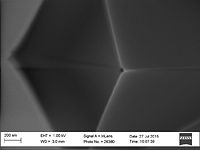

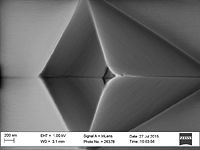

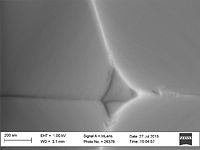

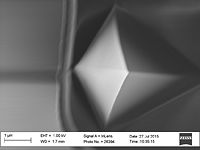

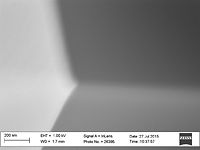

|Box1 no. 9||kabi||Blunt tip . Definitely (triangles)||[[File:Box1 no9 | |Box1 no. 9||kabi||Blunt tip . Definitely (triangles)||[[File:Box1 no9 tilt0ny2_49.jpg|200px]][[File:Box1 no9 tilt21_19.jpg|200px]] | ||

|- | |- | ||

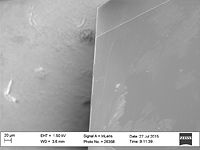

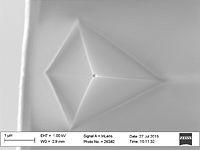

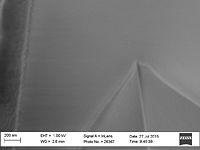

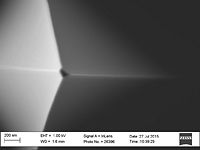

|Box1 no. 10||kabi||Blunt tip. Definitely (triangles)||[[File:Box1 no10 tilt0ny2_48.jpg|200px]] | |Box1 no. 10||kabi||Blunt tip. Definitely (triangles)||[[File:Box1 no10 tilt0ny2_48.jpg|200px]] | ||

Revision as of 12:56, 29 July 2015

Feedback to this page: click here

What scanning mode, experiment/workspace and probe should I select

| Roughness measurements | Topographic measurements with no steep/abrupt steps | Steep/abrupt steps but no high aspect ratio | High aspect ratio measurements | |

|---|---|---|---|---|

| Recommended mode | Roughness measurement can be done in both Contact, Tapping and ScanAsyst mode. We recommend ScanAsyst mode because of less chance of (non-uniform) deformation of the sample and less tip wear - and because of ease of use. | For Topographic measurements with no steep/abrupt steps we also recommend ScanAsyst mode due to less chance of (non-uniform) deformation of the sample and less tip wear - and because of ease of use. | For Steep/abrupt steps but no high aspect ratio structures we still recommend ScanAsyst mode due to ease of use and lower top wear. | For High aspect ratio measurements we recommend Tapping mode. There is not yet a ScanAsyst probe developed for high aspect ratio. Therefore we recommend Tapping mode. |

| Recommended probes | ScanAsyst in air | ScanAsyst in air | ScanAsyst in air for ScanAsyst mode

TAP300Al-G for Tapping mode |

AR5T-NCHR |

| Recommended experiment/Workspace |

QNM in air* |

QNM in air* |

QNM in air* | TappingMode 300nm trench (for steps <~1µm)

Tappping mode in air - 6µm Deep Trench (for steps >1~µm) |

*By choosing the work space/experiment QNM in air (Mechanical properties - QNM in air) scanAsyst is included and so are the nanomechanical properties like modulus, adhesion, dissipation and deformation.

More information about de different modes

Contact, Tapping and Peak Force Tapping

Please flowing this link to Brukers homepage: Introduction_to_Brukers_ScanAsyst_and_PeakForce_Tapping_Atomic_Force_Microscopy_Technology_AFM_AN133.pdf

PeakForce tapping and quantitative nanomechanical mapping

Please flowing this link to Brukers homepage: PeakForce tapping and Nanomechanical option

Peak Force KPFM (Kelvin Probe Force Microscopy)

Please flowing this link to Brukers homepage: pf-kpfm.html