Specific Process Knowledge/Characterization/AFM: Atomic Force Microscopy/Workspaces

Jump to navigation

Jump to search

Feedback to this page: click here

This page is written by Berit Herstrøm @ DTU Nanolab

What scanning mode, experiment/workspace and probe should I select

| Roughness measurements | Topographic measurements with no steep/abrupt steps | Steep/abrupt steps but no high aspect ratio | High aspect ratio measurements | Large area fast scan | |

|---|---|---|---|---|---|

| Recommended mode | Roughness measurement can be done in both Contact, Tapping and ScanAsyst mode. We recommend ScanAsyst mode because of less chance of (non-uniform) deformation of the sample and less tip wear - and because of ease of use. However it also works fine in tapping mode. | For Topographic measurements with no steep/abrupt steps we also recommend Tapping mode on most samples. Only on very soft samples (e.g. cells) we recommend ScanAsyst due to less chance of (non-uniform) deformation of the sample - or if you need QNM data. We mainly recommend Tapping mode because we experience less problems when the tip end is slightly broken. | For Steep/abrupt steps but no high aspect ratio structures we still recommend Tapping mode unless you need need QNM data. | For High aspect ratio measurements we recommend Tapping mode. We do not have experience with ScanAsyst therefore we recommend Tapping mode. | For large scan areas where you prioritize to scan fast then you can use contact mode. Here you can scan with scan rate of up to 2.43 Hz |

| Recommended probes | Tap150Al-G or ScanAsyst in air | Tap150Al-G or ScanAsyst in air | Tap150Al-G or ScanAsyst in air for ScanAsyst mode

Tap150Al-G or TAP300Al-G for Tapping mode |

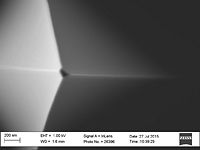

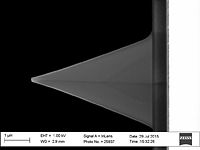

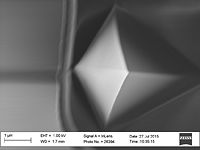

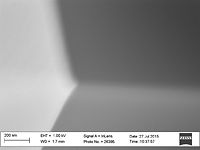

AR5T-NCHR or | SNL |

| Recommended experiment/Workspace |

Check the user manual in LabManager |

Check the user manaual in LabManager |

Check the user manaual in LabManager | TappingMode 300nm trench (for steps <~1µm)

Tappping mode in air - 6µm Deep Trench (for steps >1~µm) |

Standard Contact mode |

*By choosing the work space/experiment QNM in air (Mechanical properties - QNM in air) scanAsyst is included and so are the nanomechanical properties like modulus, adhesion, dissipation and deformation.

More information about de different modes

Contact, Tapping and Peak Force Tapping

Please flowing this link to down load the file from LabManager (Requires login):

Introduction to Bruker ScanAsyst and PeakForce tapping AFM technology

PeakForce tapping and quantitative nanomechanical mapping

- Application note on QNM: requires login

Peak Force KPFM (Kelvin Probe Force Microscopy)

- Application note on KPFM: File:PeakForce-Kelvin-Probe-Force-Microscopy-App-Note-BRUKER.pdf - used with permission