Specific Process Knowledge/Lithography/UVExposure: Difference between revisions

No edit summary |

No edit summary |

||

| Line 11: | Line 11: | ||

'''The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:''' | '''The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:''' | ||

Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view& | Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&page_id=169 LabManager] | ||

Revision as of 07:37, 12 June 2013

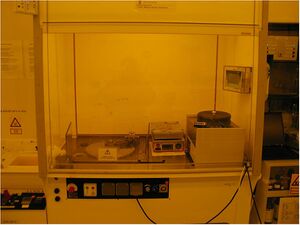

Inclined UV lamp

The Inclined UV lamp is 1000 W Hg(Xe)lamp source designed for near UV, 350-450nm, mid UV, 260-320nm, and deep UV, 220-260nm exposures of resists and polymers. The exposure source can be also used to make an inclined exposure in air or in the media tank.

The toll was purchased in February 2009 from Newport company. The exposure lamp has a official name: Oriel Flood Exposure Source, unit 92540. All other parts of equipment: substrate and mask holder with media tank, exhaust box around the tool, timer controller, were designed and build at Danchip workshop.

The substrate and mask holder with a media tank was designed as part of Master Thesis of DTU Nanotech, Andres Kristensen group. The exhaust box was made as part of safety and the timer controller was build to control exposure time.

The technical specification and the general outline of the equipment can be found in LabManager.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager: Equipment info in LabManager