|

|

| Line 331: |

Line 331: |

| |} | | |} |

| |- | | |- |

| |}

| |

|

| |

|

| |

|

| |

|

| |

| {| border="2" cellpadding="0" cellspacing="0" style="text-align:center;"

| |

| |-

| |

| ! rowspan="2" width="40"| Date

| |

| ! colspan="2" width="120"| Substrate Information

| |

| ! colspan="4" | Process Information

| |

| ! colspan="2" | Results

| |

| |-

| |

| ! width="30" | Wafer info

| |

| ! width="40" | Material/ Exposed area

| |

| ! width="40" | Condi- tioning

| |

| ! width="40" | Recipe

| |

| ! width="40" | Wafer ID

| |

| ! width="40" | Comments

| |

| ! width="400" |[[Specific Process Knowledge/Etch/DRIE-Pegasus/picoscope|Picoscope]]

| |

| ! width="400" |Numbers

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka05 wafer,

| |

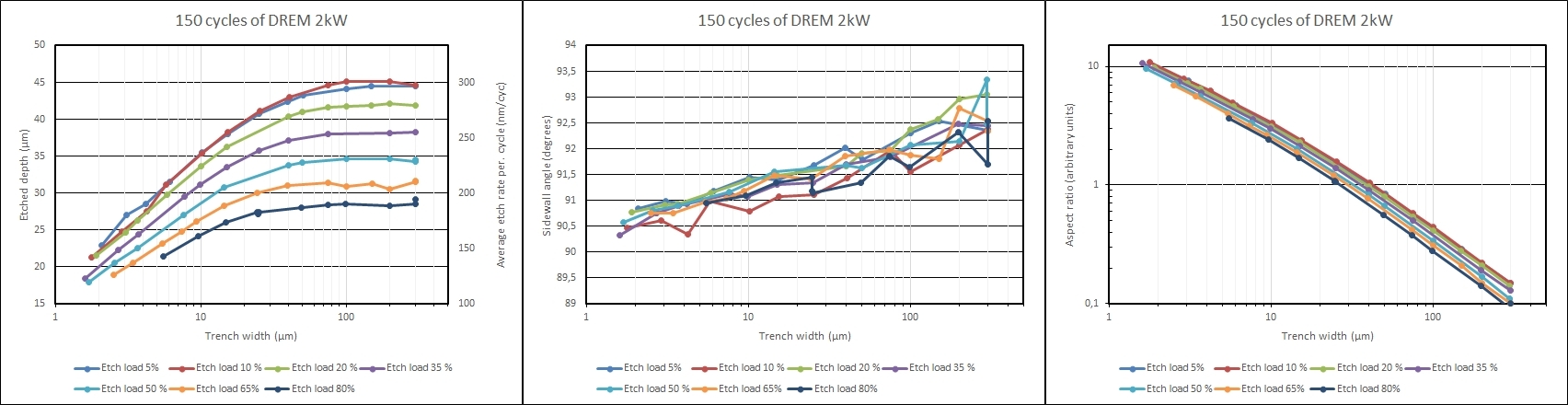

| |Si / 5%

| |

| |S022327 DREM 2kW RF MU runs

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022328

| |

| |Resist etch rate: 62 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| |

| |

| [[file:S022328.gif |120px|frameless ]]

| |

| [[file:S022328 01.gif |120px|frameless ]]

| |

| [[file:S022328 02.gif |120px|frameless ]]

| |

| [[file:S022328 03.gif |120px|frameless ]]

| |

| [[file:S022328 04.gif |120px|frameless ]]

| |

| [[file:S022328 05.gif |120px|frameless ]]

| |

| [[file:S022328 06.gif |120px|frameless ]]

| |

| [[file:S022328 07.gif |120px|frameless ]]

| |

| [[file:S022328 08.gif |120px|frameless ]]

| |

| [[file:S022328 09.gif |120px|frameless ]]

| |

| [[file:S022328 10.gif |120px|frameless ]]

| |

| [[file:S022328 11.gif |120px|frameless ]]

| |

| [[file:S022328 12.gif |120px|frameless ]]

| |

| [[file:S022328 13.gif |120px|frameless ]]

| |

| [[file:S022328 14.gif |120px|frameless ]]

| |

| [[file:S022328 15.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022328 |120px|frameless ]] -->

| |

| <!-- [[/S022328 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a060.png a060]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a059.png a059]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a058.png a058]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a057.png a057]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a056.png a056]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a055.png a055]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a054.png a054]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a053.png a053]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a052.png a052]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a051.png a051]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a050.png a050]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022328a049.png a049]'''

| |

| |-

| |

| | Trench width (um)||2.08||3.1||4.2||6.08||10.22||15.27||25.26||39.7||50.5||99.82||150.09||299.56

| |

| |-

| |

| | Etched depth (um)||22.96||27.05||28.46||31.57||35.48||37.96||40.7||42.39||43.24||44.09||44.54||44.56

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||2.09||2.46||2.59||2.87||3.23||3.45||3.7||3.85||3.93||4.01||4.05||4.05

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||153||180||190||210||237||253||271||283||288||294||297||297

| |

| |-

| |

| | Sidewall bowing (%)||0.1||0.6||0.2||0.6||0.1||0.2||-0.1||0.2||-0.4||-0.3||-0.3||-1.1

| |

| |-

| |

| | Sidewall angle (degs)||90.85||90.98||90.94||91.18||91.45||91.4||91.68||92.02||91.78||92.3||92.53||92.35

| |

| |-

| |

| | Bottom bowing (%)||16.93||14.87||20.32||20.1||19.02||17.6||14.71||13.78||10.7||6.84||4.53||2.34

| |

| |-

| |

| |Aspect ratio||9.5||7.61||6.12||4.71||3.2||2.35||1.54||1.03||0.84||0.43||0.29||0.15

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022328a049.png |120px|frameless ]]

| |

| [[file:S022328a050.png |120px|frameless ]]

| |

| [[file:S022328a051.png |120px|frameless ]]

| |

| [[file:S022328a052.png |120px|frameless ]]

| |

| [[file:S022328a053.png |120px|frameless ]]

| |

| [[file:S022328a054.png |120px|frameless ]]

| |

| [[file:S022328a055.png |120px|frameless ]]

| |

| [[file:S022328a056.png |120px|frameless ]]

| |

| [[file:S022328a057.png |120px|frameless ]]

| |

| [[file:S022328a058.png |120px|frameless ]]

| |

| [[file:S022328a059.png |120px|frameless ]]

| |

| [[file:S022328a060.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka10 wafer,

| |

| |Si / 10%

| |

| |S022328 +1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022329

| |

| |Resist etch rate: 60 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022329.gif |120px|frameless ]]

| |

| [[file:S022329 01.gif |120px|frameless ]]

| |

| [[file:S022329 02.gif |120px|frameless ]]

| |

| [[file:S022329 03.gif |120px|frameless ]]

| |

| [[file:S022329 04.gif |120px|frameless ]]

| |

| [[file:S022329 05.gif |120px|frameless ]]

| |

| [[file:S022329 07.gif |120px|frameless ]]

| |

| [[file:S022329 08.gif |120px|frameless ]]

| |

| [[file:S022329 09.gif |120px|frameless ]]

| |

| [[file:S022329 10.gif |120px|frameless ]]

| |

| [[file:S022329 11.gif |120px|frameless ]]

| |

| [[file:S022329 12.gif |120px|frameless ]]

| |

| [[file:S022329 13.gif |120px|frameless ]]

| |

| [[file:S022329 14.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022329 |120px|frameless ]] -->

| |

| <!-- [[/S022329 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a061.png a061]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a062.png a062]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a063.png a063]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a064.png a064]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a065.png a065]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a066.png a066]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a067.png a067]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a068.png a068]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a069.png a069]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a070.png a070]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a071.png a071]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022329a072.png a072]'''

| |

| |-

| |

| | Trench width (um)||1.78||2.88||4.24||5.78||10.22||15.36||25.48||40.51||75.63||100.86||200.75||299.63

| |

| |-

| |

| | Etched depth (um)||21.26||24.82||27.54||31.1||35.34||38.21||41.17||42.98||44.58||45.15||45.16||44.68

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.93||2.26||2.5||2.83||3.21||3.47||3.74||3.91||4.05||4.1||4.11||4.06

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||142||165||184||207||236||255||274||287||297||301||301||298

| |

| |-

| |

| | Sidewall bowing (%)||-0.2||0.2||-0.1||0.2||-0.2||-0.4||-0.2||-0.8||-0.6||-0.7||-1.3||-1.4

| |

| |-

| |

| | Sidewall angle (degs)||90.47||90.61||90.35||90.98||90.78||91.08||91.11||91.43||91.97||91.55||92.07||92.37

| |

| |-

| |

| | Bottom bowing (%)||26.03||15.16||18.16||17.1||17.51||17.21||15.48||13.54||8.58||6.93||3.43||2.43

| |

| |-

| |

| |Aspect ratio||10.89||7.92||6.26||4.94||3.31||2.38||1.57||1.04||0.58||0.44||0.22||0.15

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022329a061.png |120px|frameless ]]

| |

| [[file:S022329a062.png |120px|frameless ]]

| |

| [[file:S022329a063.png |120px|frameless ]]

| |

| [[file:S022329a064.png |120px|frameless ]]

| |

| [[file:S022329a065.png |120px|frameless ]]

| |

| [[file:S022329a066.png |120px|frameless ]]

| |

| [[file:S022329a067.png |120px|frameless ]]

| |

| [[file:S022329a068.png |120px|frameless ]]

| |

| [[file:S022329a069.png |120px|frameless ]]

| |

| [[file:S022329a070.png |120px|frameless ]]

| |

| [[file:S022329a071.png |120px|frameless ]]

| |

| [[file:S022329a072.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

|

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka20 wafer,

| |

| |Si / 20%

| |

| |S022329 +1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022330

| |

| |Resist etch rate: 59 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022330.gif |120px|frameless ]]

| |

| [[file:S022330 02.gif |120px|frameless ]]

| |

| [[file:S022330 03.gif |120px|frameless ]]

| |

| [[file:S022330 04.gif |120px|frameless ]]

| |

| [[file:S022330 05.gif |120px|frameless ]]

| |

| [[file:S022330 06.gif |120px|frameless ]]

| |

| [[file:S022330 07.gif |120px|frameless ]]

| |

| [[file:S022330 08.gif |120px|frameless ]]

| |

| [[file:S022330 09.gif |120px|frameless ]]

| |

| [[file:S022330 10.gif |120px|frameless ]]

| |

| [[file:S022330 12.gif |120px|frameless ]]

| |

| [[file:S022330 13.gif |120px|frameless ]]

| |

| [[file:S022330 14.gif |120px|frameless ]]

| |

| [[file:S022330 15.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022330 |120px|frameless ]] -->

| |

| <!-- [[/S022330 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a086.png a086]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a085.png a085]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a084.png a084]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a083.png a083]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a082.png a082]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a081.png a081]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a080.png a080]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a078.png a078]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a077.png a077]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a076.png a076]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a075.png a075]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a074.png a074]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022330a073.png a073]'''

| |

| |-

| |

| | Trench width (um)||1.91||3.04||3.68||5.89||10.08||15.02||40.03||49.99||75.51||100.03||148.99||199.75||298.84

| |

| |-

| |

| | Etched depth (um)||21.58||24.69||26.33||29.81||33.68||36.25||40.32||40.95||41.68||41.77||41.84||42.1||41.82

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.96||2.24||2.39||2.71||3.06||3.3||3.67||3.72||3.79||3.8||3.8||3.83||3.8

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||144||165||176||199||225||242||269||273||278||278||279||281||279

| |

| |-

| |

| | Sidewall bowing (%)||0.2||0.4||0.3||0.4||0.4||0.1||-0.1||-0.5||-0.6||-0.5||-0.6||-0.8||-0.3

| |

| |-

| |

| | Sidewall angle (degs)||90.77||90.91||90.93||91.14||91.39||91.49||91.66||91.91||91.96||92.38||92.57||92.96||93.05

| |

| |-

| |

| | Bottom bowing (%)||23.69||15.29||19.28||16.95||17.41||17.41||12.51||11.52||8.37||6.7||4.3||3.23||2.03

| |

| |-

| |

| |Aspect ratio||9.8||7.2||6.42||4.6||3.1||2.28||0.98||0.8||0.54||0.41||0.28||0.21||0.14

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022330a073.png |120px|frameless ]]

| |

| [[file:S022330a074.png |120px|frameless ]]

| |

| [[file:S022330a075.png |120px|frameless ]]

| |

| [[file:S022330a076.png |120px|frameless ]]

| |

| [[file:S022330a077.png |120px|frameless ]]

| |

| [[file:S022330a078.png |120px|frameless ]]

| |

| [[file:S022330a079.png |120px|frameless ]]

| |

| [[file:S022330a080.png |120px|frameless ]]

| |

| [[file:S022330a081.png |120px|frameless ]]

| |

| [[file:S022330a082.png |120px|frameless ]]

| |

| [[file:S022330a083.png |120px|frameless ]]

| |

| [[file:S022330a084.png |120px|frameless ]]

| |

| [[file:S022330a085.png |120px|frameless ]]

| |

| [[file:S022330a086.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

|

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka35 wafer,

| |

| |Si / 35%

| |

| |S022330 +1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022331

| |

| |Resist etch rate: 66 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022331.gif |120px|frameless ]]

| |

| [[file:S022331 01.gif |120px|frameless ]]

| |

| [[file:S022331 02.gif |120px|frameless ]]

| |

| [[file:S022331 03.gif |120px|frameless ]]

| |

| [[file:S022331 04.gif |120px|frameless ]]

| |

| [[file:S022331 05.gif |120px|frameless ]]

| |

| [[file:S022331 06.gif |120px|frameless ]]

| |

| [[file:S022331 07.gif |120px|frameless ]]

| |

| [[file:S022331 08.gif |120px|frameless ]]

| |

| [[file:S022331 09.gif |120px|frameless ]]

| |

| [[file:S022331 10.gif |120px|frameless ]]

| |

| [[file:S022331 11.gif |120px|frameless ]]

| |

| [[file:S022331 12.gif |120px|frameless ]]

| |

| [[file:S022331 13.gif |120px|frameless ]]

| |

| [[file:S022331 14.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022331 |120px|frameless ]] -->

| |

| <!-- [[/S022331 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a087.png a087]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a088.png a088]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a089.png a089]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a090.png a090]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a091.png a091]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a092.png a092]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a093.png a093]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a094.png a094]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a095.png a095]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a096.png a096]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022331a097.png a097]'''

| |

| |-

| |

| | Trench width (um)||1.61||2.71||3.71||7.69||9.87||15.04||25.1||40.03||75.03||199.26||299.66

| |

| |-

| |

| | Etched depth (um)||18.41||22.24||24.41||29.54||31.11||33.55||35.77||37.1||37.96||38.18||38.24

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.67||2.02||2.22||2.69||2.83||3.05||3.25||3.37||3.45||3.47||3.48

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||123||148||163||197||207||224||238||247||253||255||255

| |

| |-

| |

| | Sidewall bowing (%)||-0.2||0.1||0.1||0.4||0.2||0.1||-0.3||-0.2||-0.5||-1.1||-1.2

| |

| |-

| |

| | Sidewall angle (degs)||90.33||90.75||90.89||91.13||91.07||91.31||91.34||91.69||91.84||92.49||92.44

| |

| |-

| |

| | Bottom bowing (%)||24.26||20.15||19.99||19.05||17.3||16.29||16.68||13.21||7.68||3.61||2.18

| |

| |-

| |

| |Aspect ratio||10.7||7.42||5.99||3.58||2.98||2.13||1.38||0.9||0.5||0.19||0.13

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022331a087.png |120px|frameless ]]

| |

| [[file:S022331a088.png |120px|frameless ]]

| |

| [[file:S022331a089.png |120px|frameless ]]

| |

| [[file:S022331a090.png |120px|frameless ]]

| |

| [[file:S022331a091.png |120px|frameless ]]

| |

| [[file:S022331a092.png |120px|frameless ]]

| |

| [[file:S022331a093.png |120px|frameless ]]

| |

| [[file:S022331a094.png |120px|frameless ]]

| |

| [[file:S022331a095.png |120px|frameless ]]

| |

| [[file:S022331a096.png |120px|frameless ]]

| |

| [[file:S022331a097.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

|

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka50 wafer,

| |

| |Si / 50%

| |

| |S022331 +1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022332

| |

| |Resist etch rate: 58 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022332.gif |120px|frameless ]]

| |

| [[file:S022332 01.gif |120px|frameless ]]

| |

| [[file:S022332 02.gif |120px|frameless ]]

| |

| [[file:S022332 03.gif |120px|frameless ]]

| |

| [[file:S022332 04.gif |120px|frameless ]]

| |

| [[file:S022332 05.gif |120px|frameless ]]

| |

| [[file:S022332 06.gif |120px|frameless ]]

| |

| [[file:S022332 07.gif |120px|frameless ]]

| |

| [[file:S022332 08.gif |120px|frameless ]]

| |

| [[file:S022332 09.gif |120px|frameless ]]

| |

| [[file:S022332 10.gif |120px|frameless ]]

| |

| [[file:S022332 11.gif |120px|frameless ]]

| |

| [[file:S022332 12.gif |120px|frameless ]]

| |

| [[file:S022332 13.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022332 |120px|frameless ]] -->

| |

| <!-- [[/S022332 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a110.png a110]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a109.png a109]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a108.png a108]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a107.png a107]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a106.png a106]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a105.png a105]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a103.png a103]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a102.png a102]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a101.png a101]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a099.png a099]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022332a098.png a098]'''

| |

| |-

| |

| | Trench width (um)||1.69||2.57||3.68||7.62||14.53||39.96||49.94||100.08||199.63||298.35||299.12

| |

| |-

| |

| | Etched depth (um)||17.88||20.47||22.58||27.07||30.78||33.82||34.11||34.67||34.66||34.26||34.54

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.63||1.86||2.05||2.46||2.8||3.07||3.1||3.15||3.15||3.11||3.14

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||119||136||151||180||205||225||227||231||231||228||230

| |

| |-

| |

| | Sidewall bowing (%)||0.1||0.1||0.1||0.2||0.2||-0.5||-0.3||-0.8||-0.7||-2||-1.5

| |

| |-

| |

| | Sidewall angle (degs)||90.58||90.8||90.9||91.17||91.56||91.68||91.62||92.08||92.15||93.34||92.48

| |

| |-

| |

| | Bottom bowing (%)||24.2||20.91||19.84||16.14||17.61||12.38||10.43||5.77||3.26||1.83||1.96

| |

| |-

| |

| |Aspect ratio||9.58||7.18||5.61||3.32||2.01||0.83||0.67||0.34||0.17||0.11||0.11

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022332a098.png |120px|frameless ]]

| |

| [[file:S022332a099.png |120px|frameless ]]

| |

| [[file:S022332a100.png |120px|frameless ]]

| |

| [[file:S022332a101.png |120px|frameless ]]

| |

| [[file:S022332a102.png |120px|frameless ]]

| |

| [[file:S022332a103.png |120px|frameless ]]

| |

| [[file:S022332a104.png |120px|frameless ]]

| |

| [[file:S022332a105.png |120px|frameless ]]

| |

| [[file:S022332a106.png |120px|frameless ]]

| |

| [[file:S022332a107.png |120px|frameless ]]

| |

| [[file:S022332a108.png |120px|frameless ]]

| |

| [[file:S022332a109.png |120px|frameless ]]

| |

| [[file:S022332a110.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

|

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka65 wafer,

| |

| |Si / 65%

| |

| |S022332 +1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW, 150 cycles or 11:00 minutes

| |

| |S022333

| |

| |Resist etch rate: 58 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022333.gif |120px|frameless ]]

| |

| [[file:S022333 01.gif |120px|frameless ]]

| |

| [[file:S022333 02.gif |120px|frameless ]]

| |

| [[file:S022333 03.gif |120px|frameless ]]

| |

| [[file:S022333 04.gif |120px|frameless ]]

| |

| [[file:S022333 05.gif |120px|frameless ]]

| |

| [[file:S022333 06.gif |120px|frameless ]]

| |

| [[file:S022333 07.gif |120px|frameless ]]

| |

| [[file:S022333 08.gif |120px|frameless ]]

| |

| [[file:S022333 09.gif |120px|frameless ]]

| |

| [[file:S022333 10.gif |120px|frameless ]]

| |

| [[file:S022333 11.gif |120px|frameless ]]

| |

| [[file:S022333 12.gif |120px|frameless ]]

| |

| [[file:S022333 13.gif |120px|frameless ]]

| |

| [[file:S022333 14.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022333 |120px|frameless ]] -->

| |

| <!-- [[/S022333 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a111.png a111]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a112.png a112]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a113.png a113]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a114.png a114]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a115.png a115]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a116.png a116]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a117.png a117]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a118.png a118]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a119.png a119]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a120.png a120]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a121.png a121]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a122.png a122]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a123.png a123]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022333a124.png a124]'''

| |

| |-

| |

| | Trench width (um)||2.5||3.42||5.44||7.37||9.37||14.4||24.44||39.54||74.69||100.04||150.41||199.78||299.94||301.31

| |

| |-

| |

| | Etched depth (um)||18.9||20.55||23.1||24.82||26.16||28.28||30.04||31.02||31.45||30.89||31.28||30.52||31.47||31.59

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.72||1.87||2.1||2.26||2.38||2.57||2.73||2.82||2.86||2.81||2.84||2.77||2.86||2.87

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||126||137||154||165||174||189||200||207||210||206||209||203||210||211

| |

| |-

| |

| | Sidewall bowing (%)||0||0.1||0.2||0.1||0.2||0.4||0.2||-0.3||-0.7||-1.4||-0.7||-0.8||-0.9||-1

| |

| |-

| |

| | Sidewall angle (degs)||90.75||90.75||90.96||91.03||91.19||91.48||91.42||91.86||91.99||91.88||91.81||92.79||92.54||92.34

| |

| |-

| |

| | Bottom bowing (%)||18.3||18.42||16.33||16.3||16.79||18.16||14.77||11.67||6.69||4.18||3.28||1.66||1.42||1.93

| |

| |-

| |

| |Aspect ratio||6.89||5.58||3.97||3.18||2.64||1.87||1.2||0.77||0.42||0.31||0.21||0.15||0.1||0.1

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022333a111.png |120px|frameless ]]

| |

| [[file:S022333a112.png |120px|frameless ]]

| |

| [[file:S022333a113.png |120px|frameless ]]

| |

| [[file:S022333a114.png |120px|frameless ]]

| |

| [[file:S022333a115.png |120px|frameless ]]

| |

| [[file:S022333a116.png |120px|frameless ]]

| |

| [[file:S022333a117.png |120px|frameless ]]

| |

| [[file:S022333a118.png |120px|frameless ]]

| |

| [[file:S022333a119.png |120px|frameless ]]

| |

| [[file:S022333a120.png |120px|frameless ]]

| |

| [[file:S022333a121.png |120px|frameless ]]

| |

| [[file:S022333a122.png |120px|frameless ]]

| |

| [[file:S022333a123.png |120px|frameless ]]

| |

| [[file:S022333a124.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

| |-

| |

| ! style="background:gainsboro; color:black;" rowspan="2"|27/4-2020

| |

| |Travka80 wafer,

| |

| |Si / 80%

| |

| |S022333 + 1min TDESC clean

| |

| |nanolab/ jmli / DREM / DREM 2kW nano, 150 cycles or 11:00 minutes

| |

| |S022334

| |

| |Resist etch rate: 79 nm/min [http://labmanager.dtu.dk/function.php?module=Processlog&view=editlog&usageid=384373 Process log entry]

| |

| | [[file:S022334.gif |120px|frameless ]]

| |

| [[file:S022334 01.gif |120px|frameless ]]

| |

| [[file:S022334 02.gif |120px|frameless ]]

| |

| [[file:S022334 03.gif |120px|frameless ]]

| |

| [[file:S022334 04.gif |120px|frameless ]]

| |

| [[file:S022334 05.gif |120px|frameless ]]

| |

| [[file:S022334 06.gif |120px|frameless ]]

| |

| [[file:S022334 07.gif |120px|frameless ]]

| |

| [[file:S022334 08.gif |120px|frameless ]]

| |

| [[file:S022334 09.gif |120px|frameless ]]

| |

| [[file:S022334 10.gif |120px|frameless ]]

| |

| [[file:S022334 11.gif |120px|frameless ]]

| |

| [[file:S022334 12.gif |120px|frameless ]]

| |

| [[file:S022334 13.gif |120px|frameless ]]

| |

| [[file:S022334 14.gif |120px|frameless ]]

| |

| <!-- Add picoscope links here:[[file:S022333 |120px|frameless ]] -->

| |

| <!-- [[/S022334 | Single gifs ]] -->

| |

| |

| |

| {| {{table}}

| |

| | align="center" style="background:#f0f0f0;"|'''SEM image:'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a136.png a136]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a135.png a135]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a134.png a134]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a133.png a133]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a126.png a126]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a125.png a125]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a132.png a132]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a131.png a131]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a130.png a130]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a129.png a129]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a128.png a128]'''

| |

| | align="center" style="background:#f0f0f0;"|'''[http://labadviser.nanolab.dtu.dk/index.php/File:S022334a127.png a127]'''

| |

| |-

| |

| | Trench width (um)||5.51||9.61||14.79||24.6||24.8||25.02||49.42||74.63||99.55||199.49||299.49||299.54

| |

| |-

| |

| | Etched depth (um)||21.45||24.21||25.99||27.45||27.15||27.35||28.03||28.38||28.48||28.23||28.52||29.16

| |

| |-

| |

| | <span title="The etch rate will drop when the aspect ratio increases "> Etch rate (um/min)</span>||1.95||2.2||2.36||2.5||2.47||2.49||2.55||2.58||2.59||2.57||2.59||2.65

| |

| |-

| |

| | <span title="The etch rate pr cycle will drop if the aspect ratio is large "> Etch rate (nm/cyc) </span>||143||161||173||183||181||182||187||189||190||188||190||194

| |

| |-

| |

| | Sidewall bowing (%)||0.4||0.4||0.3||-0.3||-0.1||-0.6||-0.6||-0.7||-0.5||-1||-0.3||-1.2

| |

| |-

| |

| | Sidewall angle (degs)||90.95||91.1||91.34||91.44||91.19||91.14||91.35||91.86||91.65||92.32||91.7||92.54

| |

| |-

| |

| | Bottom bowing (%)||13.55||16.66||16.02||14.8||13.59||14.6||8.88||5.86||4.36||2.14||1.84||1.96

| |

| |-

| |

| |Aspect ratio||3.66||2.41||1.69||1.09||1.07||1.07||0.56||0.38||0.28||0.14||0.09||0.1

| |

| |-

| |

| |}

| |

| |-

| |

| | style="background:gainsboro; color:black;" colspan="8"|

| |

| [[file:S022334a125.png |120px|frameless ]]

| |

| [[file:S022334a126.png |120px|frameless ]]

| |

| [[file:S022334a127.png |120px|frameless ]]

| |

| [[file:S022334a128.png |120px|frameless ]]

| |

| [[file:S022334a129.png |120px|frameless ]]

| |

| [[file:S022334a130.png |120px|frameless ]]

| |

| [[file:S022334a131.png |120px|frameless ]]

| |

| [[file:S022334a132.png |120px|frameless ]]

| |

| [[file:S022334a133.png |120px|frameless ]]

| |

| [[file:S022334a134.png |120px|frameless ]]

| |

| [[file:S022334a135.png |120px|frameless ]]

| |

| [[file:S022334a136.png |120px|frameless ]]

| |

| |-

| |

| | colspan="9"| .

| |

| |-

| |

| |} | | |} |

|

| |

|