Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano10: Difference between revisions

New page: == The nano1.0 recipe == {| border="2" cellpadding="2" cellspacing="1" |+ '''Recipe nano1.0''' |- ! rowspan="6" align="center"| Recipe | Gas | C<sub>4</sub>F<sub>8</sub> 38 sccm, HBr 15 ... |

No edit summary |

||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Etch/DRIE-Pegasus/nanoetch/nano10 click here]''' | |||

<!--Checked for updates on 30/7-2018 - ok/jmli --> | |||

<!--Checked for updates on 5/10-2020 - ok/jmli --> | |||

<!--Checked for updates on 4/9-2025 - ok/jmli --> | |||

== The nano1.0 recipe == | == The nano1.0 recipe == | ||

{{Template:Author-jmli1}} | |||

<!--Checked for updates on 2/02-2023 - ok/jmli --> | |||

{| border="2" cellpadding="2" cellspacing="1" | {| border="2" cellpadding="2" cellspacing="1" | ||

| Line 6: | Line 12: | ||

! rowspan="6" align="center"| Recipe | ! rowspan="6" align="center"| Recipe | ||

| Gas | | Gas | ||

| C<sub>4</sub>F<sub>8</sub> 38 sccm, | | C<sub>4</sub>F<sub>8</sub> 38 sccm, SF<sub>6</sub> 52 sccm | ||

|- | |- | ||

| Pressure | | Pressure | ||

| | | 4 mTorr, Strike 3 secs @ 15 mTorr | ||

|- | |- | ||

| Power | | Power | ||

| | | 800 W CP, 50 W PP | ||

|- | |- | ||

| Temperature | | Temperature | ||

| | | 10 degs | ||

|- | |- | ||

| Hardware | | Hardware | ||

| Line 21: | Line 27: | ||

|- | |- | ||

| Time | | Time | ||

| | | 120 secs | ||

|- | |- | ||

! rowspan="3" align="center"| Conditions | ! rowspan="3" align="center"| Conditions | ||

| Run ID | | Run ID | ||

| | | 1801 | ||

|- | |- | ||

| Conditioning | | Conditioning | ||

| Line 31: | Line 37: | ||

|- | |- | ||

| Mask | | Mask | ||

| | | 1dfhj10 nm zep etched down to 6dgh4 nm | ||

|- | |- | ||

|} | |} | ||

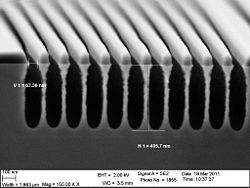

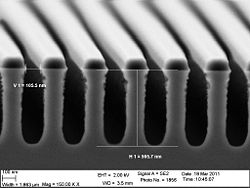

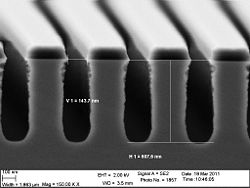

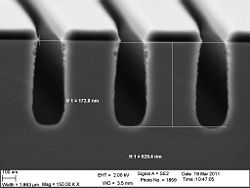

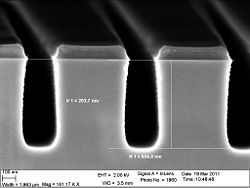

<gallery caption="The results of the | <gallery caption="The results of the nano1.0 recipe" widths="250" heights="200" perrow="3"> | ||

image: | image:WF_2C3feb2011-030.jpg|The 30 nm trenches | ||

image: | image:WF_2C3feb2011-060.jpg|The 60 nm trenches | ||

image: | image:WF_2C3feb2011-090.jpg|The 90 nm trenches | ||

image: | image:WF_2C3feb2011-120.jpg|The 120 nm trenches | ||

image: | image:WF_2C3feb2011-150.jpg|The 150 nm trenches | ||

C4F8 52 sccm, SF6 38 sccm, 4 mTorr, Strike 3 secs @ 15 mTorr, 800 W CP, 50 W PP, 10 degs, 120 secs | |||

</gallery> | </gallery> | ||

{| {{table}} | |||

| align="center" style="background:#f0f0f0;"|'''Nominal trench line width''' | |||

| align="center" style="background:#f0f0f0;"|'''''' | |||

| align="center" style="background:#f0f0f0;"|'''30''' | |||

| align="center" style="background:#f0f0f0;"|'''60''' | |||

| align="center" style="background:#f0f0f0;"|'''90''' | |||

| align="center" style="background:#f0f0f0;"|'''120''' | |||

| align="center" style="background:#f0f0f0;"|'''150''' | |||

| align="center" style="background:#f0f0f0;"|'''Avg''' | |||

| align="center" style="background:#f0f0f0;"|'''Std''' | |||

|- | |||

| Etch rates||nm/min||239||281||306||320||328||295||36 | |||

|- | |||

| Sidewall angle||degs||93||94||93||92||93||93||1 | |||

|- | |||

| CD loss||nm/edge||-1||-5||-11||-9||-32||-11||12 | |||

|- | |||

| CD loss foot||nm/edge||-1||-5||-11||-9||-2||-5||5 | |||

|- | |||

| Bowing||||41||33||29||30||22||31||7 | |||

|- | |||

| Curvature||||-51||-50||-43||-39||-42||-45||5 | |||

|- | |||

| zep||nm/min||||||||||||46|| | |||

|- | |||

| | |||

|} | |||

== Comments == | |||

The process looks to be too etch aggressive, not enough passivation. Consider any or all of the following: | |||

* Decreasing the wafer temperature (make more passivant) | |||

* Increasing C4F8 flow (make more passivant) | |||

* Increasing platen power (make more directional) | |||

* Decreasing coil power (make less etch-aggressive and more directional. | |||

Also, if the tool has Short Funnel and 5mm spacers fitted, it may be too close to the plasma - previous good nano-scale etch result was achieved with Long Funnel and 100mm spacers. | |||

The conditions are similar to the nano-etch conditions for acceptance process C: | |||

{| border="2" cellpadding="2" cellspacing="1" | |||

|- | |||

| | |||

| Etch | |||

|- | |||

| Gas Flow (sccm) | |||

| SF<sub>6</sub> 38 + '''C<sub>4</sub>F<sub>8</sub> 70''' | |||

|- | |||

| Pressure (mT) | |||

| 4 | |||

|- | |||

| APC angle (%) | |||

| 33.2 | |||

|- | |||

| Coil power (W) | |||

| '''450''' | |||

|- | |||

| Matching (Forward/ Load) | |||

| L/ 33 & T/ 43 | |||

|- | |||

| HF Platen power (W) | |||

| '''100''' | |||

|- | |||

| Matching (Forward/ Load) | |||

| L/ 49 & T/ 53 | |||

|- | |||

| Time | |||

| 01:30 | |||

|- | |||

| Hardware configuration | |||

| 150mm Long funnel, with baffle & 100mm spacers | |||

|- | |||

| APC Gain | |||

| 7.5 (default) | |||

|- | |||

| Platen Temperature | |||

| 10°C | |||

|} | |||

The highlighted sections are the main differences between the Process C conditions Vs new Imprint Trenches conditions: all of the changes would push the process to be more passivant, less etch aggressive and more directional. | |||

Is there any reason why these conditions are not suitable for the Imprint Trenches etch? | |||

Latest revision as of 09:27, 4 September 2025

Feedback to this page: click here

The nano1.0 recipe

Unless otherwise stated, all content on this page was created by Jonas Michael-Lindhard, DTU Nanolab

| Recipe | Gas | C4F8 38 sccm, SF6 52 sccm |

|---|---|---|

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | |

| Power | 800 W CP, 50 W PP | |

| Temperature | 10 degs | |

| Hardware | 100 mm Spacers | |

| Time | 120 secs | |

| Conditions | Run ID | 1801 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

| Mask | 1dfhj10 nm zep etched down to 6dgh4 nm |

- The results of the nano1.0 recipe

-

The 30 nm trenches

-

The 60 nm trenches

-

The 90 nm trenches

-

The 120 nm trenches

-

The 150 nm trenches

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Avg | Std |

| Etch rates | nm/min | 239 | 281 | 306 | 320 | 328 | 295 | 36 |

| Sidewall angle | degs | 93 | 94 | 93 | 92 | 93 | 93 | 1 |

| CD loss | nm/edge | -1 | -5 | -11 | -9 | -32 | -11 | 12 |

| CD loss foot | nm/edge | -1 | -5 | -11 | -9 | -2 | -5 | 5 |

| Bowing | 41 | 33 | 29 | 30 | 22 | 31 | 7 | |

| Curvature | -51 | -50 | -43 | -39 | -42 | -45 | 5 | |

| zep | nm/min | 46 | ||||||

Comments

The process looks to be too etch aggressive, not enough passivation. Consider any or all of the following:

- Decreasing the wafer temperature (make more passivant)

- Increasing C4F8 flow (make more passivant)

- Increasing platen power (make more directional)

- Decreasing coil power (make less etch-aggressive and more directional.

Also, if the tool has Short Funnel and 5mm spacers fitted, it may be too close to the plasma - previous good nano-scale etch result was achieved with Long Funnel and 100mm spacers.

The conditions are similar to the nano-etch conditions for acceptance process C:

| Etch | |

| Gas Flow (sccm) | SF6 38 + C4F8 70 |

| Pressure (mT) | 4 |

| APC angle (%) | 33.2 |

| Coil power (W) | 450 |

| Matching (Forward/ Load) | L/ 33 & T/ 43 |

| HF Platen power (W) | 100 |

| Matching (Forward/ Load) | L/ 49 & T/ 53 |

| Time | 01:30 |

| Hardware configuration | 150mm Long funnel, with baffle & 100mm spacers |

| APC Gain | 7.5 (default) |

| Platen Temperature | 10°C |

The highlighted sections are the main differences between the Process C conditions Vs new Imprint Trenches conditions: all of the changes would push the process to be more passivant, less etch aggressive and more directional.

Is there any reason why these conditions are not suitable for the Imprint Trenches etch?