Specific Process Knowledge/Lithography/MiR: Difference between revisions

No edit summary |

mNo edit summary |

||

| (5 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{:Specific Process Knowledge/Lithography/authors_generic}} | |||

AZ MiR 701 is a positive UV photoresist. | '''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Lithography/MiR click here]''' | ||

[[Category: Lithography|Resist]] | |||

[[Category: Resist|AZ MiR 701]] | |||

__TOC__ | |||

==Resist description== | |||

AZ MiR 701 is a positive UV photoresist. It is considered to have high selectivity for dry etching. | |||

==Spin coating== | ==Spin coating== | ||

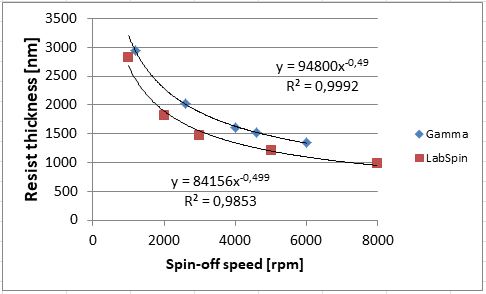

[[Image:MiRspincurves.JPG|640px|thumb|Spin curves for AZ MiR 701 (29 cps) using a 30 s spin-off, and a 60 s @ 90°C proximity softbake]] | |||

'''Typical spin parameters:''' | |||

*Spin off: 30-60 s | |||

*Soft bake: 60 s @ 90°C in proximity | |||

<br clear="all" /> | <br clear="all" /> | ||

==Exposure== | ==Exposure== | ||

'''Dehydration of resist film:'''<br> | |||

During exposure in the maskless aligners, MiR can be sensitive to dehydration by the air flow applied by the pneumatic auto-focus mechanism. This may lead to insufficient development, especially for small substrates. This problem can be alleviated by switching to the overview camera for a period of 1 minute before starting the exposure, or simply by parking the writehead away from the exposure location for 1 minute before starting the exposure. | |||

The effect can also be reduced by increasing the soft bake. | |||

==Post-exposure bake== | ==Post-exposure bake== | ||

'''Typical PEB parameters:''' | |||

*PEB temperature: 110°C | |||

*PEB time: 60 s | |||

During exposure, interaction between the incoming light and the light reflected by the substrate can cause a standing wave to form in the resist (especially true for single line/wavelength exposure). This leads to a wavy sidewall after development. The standing wave pattern can be reduced by introducing a post-exposure bake before development, which allows the activated PAC to diffuse into un-activated regions, thus smoothing the sidewall. The recommended PEB for MiR is 60 s at 110°C (for a 1 - 2 µm film). Thicker coatings may require longer bake, and substrate thickness and material may also affect the required baking time. | |||

Since the post-exposure bake is at an elevated temperature compared to the soft bake, it will cause the resist film to become 5-10% thinner (probably due to continued evaporation of solvent). A 1.5 µm thick MiR resist film will be approximately 1.4 µm after PEB. | |||

==Development== | ==Development== | ||

'''Development speed:''' | |||

*Puddle development in 2.38% TMAH (AZ 726 MIF): ~2 µm/min | |||

Latest revision as of 14:09, 25 August 2025

This section, including all images and pictures, is created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Resist description

AZ MiR 701 is a positive UV photoresist. It is considered to have high selectivity for dry etching.

Spin coating

Typical spin parameters:

- Spin off: 30-60 s

- Soft bake: 60 s @ 90°C in proximity

Exposure

Dehydration of resist film:

During exposure in the maskless aligners, MiR can be sensitive to dehydration by the air flow applied by the pneumatic auto-focus mechanism. This may lead to insufficient development, especially for small substrates. This problem can be alleviated by switching to the overview camera for a period of 1 minute before starting the exposure, or simply by parking the writehead away from the exposure location for 1 minute before starting the exposure.

The effect can also be reduced by increasing the soft bake.

Post-exposure bake

Typical PEB parameters:

- PEB temperature: 110°C

- PEB time: 60 s

During exposure, interaction between the incoming light and the light reflected by the substrate can cause a standing wave to form in the resist (especially true for single line/wavelength exposure). This leads to a wavy sidewall after development. The standing wave pattern can be reduced by introducing a post-exposure bake before development, which allows the activated PAC to diffuse into un-activated regions, thus smoothing the sidewall. The recommended PEB for MiR is 60 s at 110°C (for a 1 - 2 µm film). Thicker coatings may require longer bake, and substrate thickness and material may also affect the required baking time.

Since the post-exposure bake is at an elevated temperature compared to the soft bake, it will cause the resist film to become 5-10% thinner (probably due to continued evaporation of solvent). A 1.5 µm thick MiR resist film will be approximately 1.4 µm after PEB.

Development

Development speed:

- Puddle development in 2.38% TMAH (AZ 726 MIF): ~2 µm/min