Specific Process Knowledge/Thermal Process/BCB Curing Oven: Difference between revisions

No edit summary |

|||

| (7 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:thinfilm@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Thermal_Process/BCB_Curing_Oven click here]''' | '''Feedback to this page''': '''[mailto:thinfilm@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Thermal_Process/BCB_Curing_Oven click here]''' | ||

''This page is written by DTU Nanolab internal'' | |||

[[Category: Equipment |Thermal BCB]] | [[Category: Equipment |Thermal BCB]] | ||

[[Category: Thermal process|BCB]] | [[Category: Thermal process|BCB]] | ||

== BCB Curing Oven == | == BCB Curing Oven == | ||

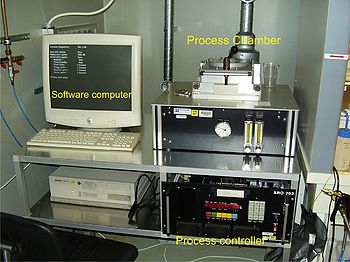

[[image:BCB oven.jpeg|350x350px|right|thumb|The BCB Curing Oven. Positioned in | [[image:BCB oven.jpeg|350x350px|right|thumb|The BCB Curing Oven. Positioned in room Cx1/ Photo: DTU Nanolab internal]] | ||

The BCB Curing Oven is mainly used for curing of BCB (bisbenzocyclobutene) and for alloying of metals in a nitrogen atmosphere. | The BCB Curing Oven is mainly used for curing of BCB (bisbenzocyclobutene, cyclotene®) and for alloying of some metals in a nitrogen atmosphere. | ||

During processing the | During processing the oven is rapidly heated by use of eight halogen lamps situated below the sample. The maximum allowed temperature is 450 <sup>o</sup>C. | ||

The oven is purged with a nitrogen flow (high or low flow). Samples are processed at atmospheric pressure or at vacuum. | |||

| Line 20: | Line 23: | ||

Here are some of the standard processes used in the BCB Curing Oven. | Here are some of the standard processes used in the BCB Curing Oven. | ||

=== BCB curing | === BCB curing=== | ||

An example of a curing recipe (BCB250BL.PDF) for a long curing process at 250°C is shown below. | |||

Content of BCB250BL.PDF: | Content of BCB250BL.PDF: | ||

<pre> | <pre> | ||

; | ; | ||

| Line 47: | Line 49: | ||

</pre> | </pre> | ||

===General processes=== | ===General processes=== | ||

There are a number of general processes named DxxxCyyy.PDF. | There are a number of general processes on the oven named DxxxCyyy.PDF. | ||

The Dxxx is the set temperature (in °C) and the Cyyy is the time (in minutes) at the set temperature. | The "Dxxx" in the recipe is the set temperature (in °C) and the "Cyyy" is the time (in minutes) at the set temperature. | ||

The oven heats to the set temperature (xxx) in 5 mins and then stays at the temperature (xxx) for a time (yyy) after which it cools to room temperature as fast as possible. | The oven heats to the set temperature (xxx) in 5 mins and then stays at the temperature (xxx) for a time (yyy), after which it cools to room temperature as fast as possible. | ||

The program sequence looks like this for the file D200C060.PDF: | The program sequence looks like this for the file D200C060.PDF: | ||

| Line 83: | Line 84: | ||

|style="background:LightGrey; color:black"|Temperature | |style="background:LightGrey; color:black"|Temperature | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | *Room temperature - 450<sup>o</sup>C | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Nitrogen flows | |style="background:LightGrey; color:black"|Nitrogen flows | ||

| Line 110: | Line 111: | ||

*Quartz | *Quartz | ||

*Resist (prebaked) | *Resist (prebaked) | ||

* | *Metals on Material list 1, 2 and 3 (see the cross contamination information in LabManager) | ||

|- | |- | ||

|} | |} | ||

Latest revision as of 09:58, 30 July 2024

Feedback to this page: click here

This page is written by DTU Nanolab internal

BCB Curing Oven

The BCB Curing Oven is mainly used for curing of BCB (bisbenzocyclobutene, cyclotene®) and for alloying of some metals in a nitrogen atmosphere.

During processing the oven is rapidly heated by use of eight halogen lamps situated below the sample. The maximum allowed temperature is 450 oC.

The oven is purged with a nitrogen flow (high or low flow). Samples are processed at atmospheric pressure or at vacuum.

The user manual, user APV, technical information and contact information can be found in LabManager:

Process information

Here are some of the standard processes used in the BCB Curing Oven.

BCB curing

An example of a curing recipe (BCB250BL.PDF) for a long curing process at 250°C is shown below.

Content of BCB250BL.PDF:

;

; stored 31.08.2011 at 17:55:33

{P0}

00,00:30,0020,- - - - 3 - - - -,075,250,001,005,028

01,00:10,0020,- - - 2 - - - - -

02,00:30,0020,- - - - 3 - - - -

03,00:10,0020,- - - 2 - - - - -

04,05:00,0050,H - - 2 - - - - -

05,05:00,0050,H C - 2 - - - - -

06,15:00,0100,H - 1 - - - - - -

07,45:00,0100,H C 1 - - - - - -

08,15:00,0150,H - 1 - - - - - -

09,81:00,0150,H C 1 - - - - - -

10,60:00,0250,H - 1 - - - - - -

11,60:00,0250,H C 1 - - - - - -

12,15:00,0020,- C 1 - - - - - -

13,30:00,0020,- C 1 - - - - - -

14,00:00,0010,- C - - - - - - -

General processes

There are a number of general processes on the oven named DxxxCyyy.PDF.

The "Dxxx" in the recipe is the set temperature (in °C) and the "Cyyy" is the time (in minutes) at the set temperature.

The oven heats to the set temperature (xxx) in 5 mins and then stays at the temperature (xxx) for a time (yyy), after which it cools to room temperature as fast as possible.

The program sequence looks like this for the file D200C060.PDF:

;

; stored 31.08.2011 at 18:15:47

{P0}

00,05:00,0200,H - - 2 - - - - -,075,250,001,005,028

01,60:00,0200,H C 1 - - - - - -

02,05:00,0002,- C 1 - - - - - -

03,00:00,0000,- C - - - - - - -

| Equipment | BCB Curing Oven | |

|---|---|---|

| Purpose |

| |

| Process parameter range | Temperature |

|

| Nitrogen flows |

| |

| Pressure |

| |

| Substrates

(Remember to use the right carrier wafer) |

Batch size |

|

| Allowed materials |

| |