LabAdviser/314/Microscopy 314-307/SEM/Nova/Micro 4-point probe: Difference between revisions

No edit summary |

|||

| (18 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

<!-- <span style="background:#FF2800">THIS PAGE IS UNDER CONSTRUCTION</span>[[image:Under_construction.png|200px]] --> | |||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php?title=LabAdviser/314/Microscopy_314-307/SEM/Nova/Micro 4-point probe click here]''' | |||

''This section is written by Matteo Todeschini @DTU Nanolab if nothing else is stated.'' | |||

[[Category:314]] | |||

[[Category:314-Microscopy]] | |||

= 4-point probe theory = | = 4-point probe theory = | ||

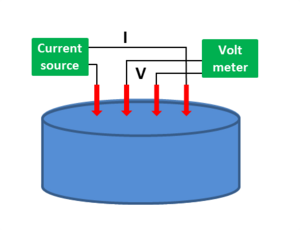

The electrical resistivity of metallic bulk and thin-film samples is usually measured by the 4-point probe technique. The classic arrangement, visible in Fig. 1, consists of four needle-like electrodes in a linear arrangement, with a current injected into the material via the outer two electrodes, while the resulting difference in electric potential is measured via the two inner electrodes. | The electrical resistivity of metallic bulk and thin-film samples is usually measured by the 4-point probe technique. The classic arrangement, visible in Fig. 1, consists of four needle-like electrodes in a linear arrangement, with a current injected into the material via the outer two electrodes, while the resulting difference in electric potential is measured via the two inner electrodes. | ||

[[File:2.png|300px|center|Fig. 1: 4-point probe setup. The current is supplied by the outer connections, the voltage drop is measured between the inner connections.]] | [[File:2.png|300px|center|thumb|Fig. 1: 4-point probe setup. The current is supplied by the outer connections, the voltage drop is measured between the inner connections.]] | ||

By using separate electrodes for the current injection and for the determination of the electric potential, the contact resistance between the metal electrodes and the material does not show up in the measured results. Since the contact resistance can be large and can strongly depend on the condition and materials of the electrodes, it is easier to interpret the data measured by the 4-point probe technique than from a 2-point probe system. If the sample has a finite size and if the spacing between the probes is | By using separate electrodes for the current injection and for the determination of the electric potential, the contact resistance between the metal electrodes and the material does not show up in the measured results. Since the contact resistance can be large and can strongly depend on the condition and materials of the electrodes, it is easier to interpret the data measured by the 4-point probe technique than from a 2-point probe system. If the sample has a finite size and if the spacing between the probes is | ||

s1= s2 = s3 = s, the resistivity is given by: | s1= s2 = s3 = s, the resistivity is given by: | ||

ρ = 2aπsV/I (1) | |||

where a is the thickness correction factor for thicknesses t equal to or less than half the probe spacing (t/s < 0.5): | where a is the thickness correction factor for thicknesses t equal to or less than half the probe spacing (t/s < 0.5): | ||

a = 0.72t/s (2) | |||

Substituting Eq. 2 in Eq. 1 we get: | Substituting Eq. 2 in Eq. 1 we get: | ||

ρ = 2aπsV/I = 4.53V/I (3) | |||

If both sides of Eq. 3 are divided by t we get: | If both sides of Eq. 3 are divided by t we get: | ||

Rs = ρ/t = 4.53V/I (4) | |||

which we refer to as sheet resistance. When the thickness t is very small respect to the spacing s, Rs is the preferred measurement quantity, being independent of any geometrical dimension and therefore a function of the material alone. | which we refer to as sheet resistance. When the thickness t is very small respect to the spacing s, Rs is the preferred measurement quantity, being independent of any geometrical dimension and therefore a function of the material alone. | ||

| Line 28: | Line 36: | ||

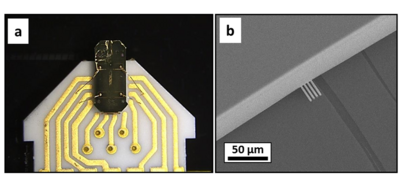

In this thesis, a variation of the classic 4-point probe method was used, called micro 4-point probe (μ4PP). This because the electrodes of the 4-point probe can easily scratch a metallic film with thickness in the nm range, thus reaching the substrate and giving inaccurate electrical measurements as result. Fig. 2a shows a μ4PP probe chip. Visible are the ceramic substrate, the Ag/Pd connector strips and the Si base from which the four cantilevers extend. For the movements, the probe chip is connected to a micromanipulator inside a SEM. Aided by SEM imaging, the probe gently touches the thin-film surface in 2-point probe mode without scratching it, followed by the collection of the data in 4-point probe mode (Fig. 2b). | In this thesis, a variation of the classic 4-point probe method was used, called micro 4-point probe (μ4PP). This because the electrodes of the 4-point probe can easily scratch a metallic film with thickness in the nm range, thus reaching the substrate and giving inaccurate electrical measurements as result. Fig. 2a shows a μ4PP probe chip. Visible are the ceramic substrate, the Ag/Pd connector strips and the Si base from which the four cantilevers extend. For the movements, the probe chip is connected to a micromanipulator inside a SEM. Aided by SEM imaging, the probe gently touches the thin-film surface in 2-point probe mode without scratching it, followed by the collection of the data in 4-point probe mode (Fig. 2b). | ||

[[File:3.png|400px|center|Fig. 2: a) General view of a μ4PP probe chip, with the ceramic substrate, the Ag/Pd connector strips and the Si base connected to the four cantilevers; b) SEM micrograph of the four Au covered SiO2 cantilevers correctly landed on the thin- | [[File:3.png|400px|center|thumb|Fig. 2: a) General view of a μ4PP probe chip, with the ceramic substrate, the Ag/Pd connector strips and the Si base connected to the four cantilevers; b) SEM micrograph of the four Au covered SiO2 cantilevers correctly landed on the thin-film surface.]] | ||

= Kleindiek micromanipulator = | = Kleindiek micromanipulator = | ||

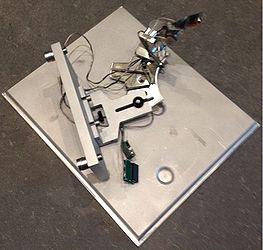

The Kleindiek Nanotechnik MM3A-EM is a plug and play micromanipulator for SEM/FIB applications, with a versatile range of modular plug-ins. The MM3A-EM can be used in most SEM/FIB instruments and offers fast setup and removal. The system consists of a base over which the micromanipulator arm is mounted ( | The Kleindiek Nanotechnik MM3A-EM is a plug and play micromanipulator for SEM/FIB applications, with a versatile range of modular plug-ins. The MM3A-EM can be used in most SEM/FIB instruments and offers fast setup and removal. The system consists of a base over which the micromanipulator arm is mounted (Fig. 3). The base can be attached to the SEM front door by two exagonal head screws (Fig. 4).The arm is connected to the external power supply through two plug-ins on a PCB board mounted on the SEM door. | ||

<gallery widths="350px" heights="250px" perrow="2" halign="center"> image:Micromanipulator alone.JPG|Fig. 3: the base with the micromanipulator mounted on it. | |||

image:Micromanipulator installed.JPG|Fig. 4: the micromanipulator mounted on the Nova NanoSEM door. </gallery> | |||

== Controlling the MM3A == | == Controlling the MM3A == | ||

The MM3A can be controlled in two ways: using the Joypad or the Nanocontroller. The possible micromanipulator movements are shown in | The MM3A can be controlled in two ways: using the Joypad or the Nanocontroller. The possible micromanipulator movements are shown in Fig. 5. The two controllers can control in either fine or coarse mode depending on the speed selection. There are six speeds available, three in coarse mode and three in fine mode. | ||

[[image:micromanipulator.png|800x800px|center|thumb| | [[image:micromanipulator.png|800x800px|center|thumb|Fig. 5: the possible movements of the micromanipulator.]] | ||

== Capres M4PP SEM Module == | == Capres M4PP SEM Module == | ||

| Line 68: | Line 60: | ||

== Module schematic == | == Module schematic == | ||

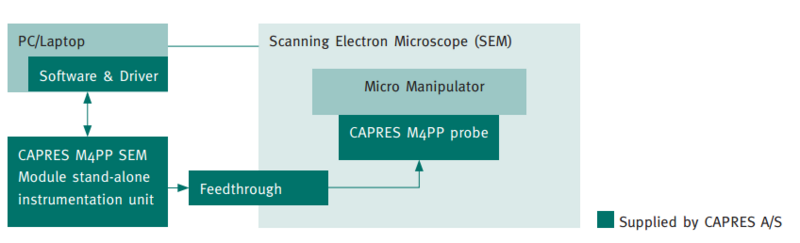

[[image:Module schematics.PNG|800x800px|center|thumb| | [[image:Module schematics.PNG|800x800px|center|thumb|Fig. 6: module schematics of the SEM Module system with all its components.]] | ||

Revision as of 14:31, 27 June 2023

Feedback to this page: 4-point probe click here

This section is written by Matteo Todeschini @DTU Nanolab if nothing else is stated.

4-point probe theory

The electrical resistivity of metallic bulk and thin-film samples is usually measured by the 4-point probe technique. The classic arrangement, visible in Fig. 1, consists of four needle-like electrodes in a linear arrangement, with a current injected into the material via the outer two electrodes, while the resulting difference in electric potential is measured via the two inner electrodes.

By using separate electrodes for the current injection and for the determination of the electric potential, the contact resistance between the metal electrodes and the material does not show up in the measured results. Since the contact resistance can be large and can strongly depend on the condition and materials of the electrodes, it is easier to interpret the data measured by the 4-point probe technique than from a 2-point probe system. If the sample has a finite size and if the spacing between the probes is s1= s2 = s3 = s, the resistivity is given by:

ρ = 2aπsV/I (1)

where a is the thickness correction factor for thicknesses t equal to or less than half the probe spacing (t/s < 0.5):

a = 0.72t/s (2)

Substituting Eq. 2 in Eq. 1 we get:

ρ = 2aπsV/I = 4.53V/I (3)

If both sides of Eq. 3 are divided by t we get:

Rs = ρ/t = 4.53V/I (4)

which we refer to as sheet resistance. When the thickness t is very small respect to the spacing s, Rs is the preferred measurement quantity, being independent of any geometrical dimension and therefore a function of the material alone.

Micro 4-point probe

In this thesis, a variation of the classic 4-point probe method was used, called micro 4-point probe (μ4PP). This because the electrodes of the 4-point probe can easily scratch a metallic film with thickness in the nm range, thus reaching the substrate and giving inaccurate electrical measurements as result. Fig. 2a shows a μ4PP probe chip. Visible are the ceramic substrate, the Ag/Pd connector strips and the Si base from which the four cantilevers extend. For the movements, the probe chip is connected to a micromanipulator inside a SEM. Aided by SEM imaging, the probe gently touches the thin-film surface in 2-point probe mode without scratching it, followed by the collection of the data in 4-point probe mode (Fig. 2b).

Kleindiek micromanipulator

The Kleindiek Nanotechnik MM3A-EM is a plug and play micromanipulator for SEM/FIB applications, with a versatile range of modular plug-ins. The MM3A-EM can be used in most SEM/FIB instruments and offers fast setup and removal. The system consists of a base over which the micromanipulator arm is mounted (Fig. 3). The base can be attached to the SEM front door by two exagonal head screws (Fig. 4).The arm is connected to the external power supply through two plug-ins on a PCB board mounted on the SEM door.

-

Fig. 3: the base with the micromanipulator mounted on it.

-

Fig. 4: the micromanipulator mounted on the Nova NanoSEM door.

Controlling the MM3A

The MM3A can be controlled in two ways: using the Joypad or the Nanocontroller. The possible micromanipulator movements are shown in Fig. 5. The two controllers can control in either fine or coarse mode depending on the speed selection. There are six speeds available, three in coarse mode and three in fine mode.

Capres M4PP SEM Module

The Capres M4PP SEM Module expands the capabilities of standard Scanning Electron Microscopes (SEM) with in-situ Microscopic Four Point Probing (M4PP). The M4PP SEM Module consists of a probe holder that attaches to a micro manipulator inside the SEM chamber, a stand-alone instrumentation unit, and software for control and data acquisition.

The range of applications can vary from surface layer transport measurement to interconnect probing, to sheet resistance characterization, to characterization of inhomogeneous or microstructured advanced materials e.g. ultra-thin films and nanowires.

Module schematic