Specific Process Knowledge/Thin film deposition/Deposition of Silicon Oxide/IBSD of SiO2

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

Go to 'IBE/IBSD Ionfab 300' equipment page

Acceptance test for SiO2 deposition (2011) on IBE/IBSD Ionfab 300+)

| . | Acceptance Criteria |

Acceptance Result 1 |

Acceptance Result 2 |

|---|---|---|---|

| Substrate information |

|

|

|

| Material to be deposited |

The purpose of the SiO2 is to be part of a mirror: <br\> 5 quarter wavelength pairs of <br\> SiO2 <br\> TiO2 <br\> Extra quarter wavelength layer of <br\> TiO2 <br\> 5 quarter wavelength pairs of <br\> SiO2 <br\> TiO2 <br\> Design wavelength (for refractive indices and layer thicknesses): 1300nm <br\> The acceptance criteria is set up for the single SiO2 and TiO2 layers. <br\> Five runs in a row for each material. |

|

|

| Deposition thickness |

|

|

|

| Deposition rate |

|

One standard deviation |

Only made once |

| Thickness uniformity |

|

|

|

| Reproducibility |

|

|

|

| Stress |

|

|

|

| Refractive index | . |

|

|

| Recipe 1 | Recipe 2 | |

|---|---|---|

| Platen angle | 15 degrees | 10 degrees |

| Platen rotation speed | 20 rpm | 20 rpm |

| Ar(N) flow | 4 sccm | 4 sccm |

| Ar(dep. source) flow | 9 sccm | 8 sccm |

| I(N) | 310 mA | 320 mA |

| Power | 675 W | 700 W |

| I(B) | 310 mA | 280 mA |

| V(B) | 1200 V | 1100 V |

| Vacc(B) | 400 V | 400 V |

| Deposition time | 29 min | 37 min |

Other results

Roughness of the surface

Measured with the Optical profiler - PSI mode (on one sample from the acceptance test): Sa= 0.6 nm

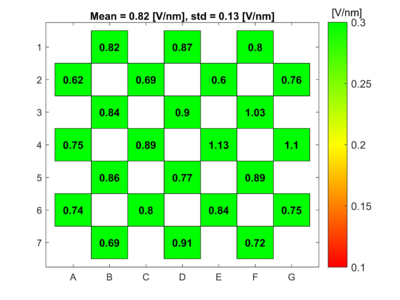

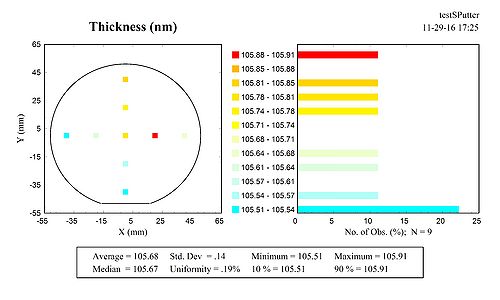

Uniformity and break down voltage by Mathias Engholm 2016-11-29

Mathias made 105.62nm SiO2 on a test silicon wafer and on his sample wafer. The sample wafer had gold/Cr on the surface and that had to be electrically isolated. The uniformity over the wafer of the oxide was 0.19% over 9 points - this is better than he has achieved when oxidizing in a furnace. He anodic bonded the wafer without problems. He measured the breakdown voltage and got 0.82+/+ 0.13 V/nm over 24 points. This is just as good as the oxide from the furnaces. Before his deposition he ran a 20 min heat up and 40min dummy deposition to clean the target. This was done with a bright new target and with the small deposition grids mounted.