Specific Process Knowledge/Thin film deposition/ALD2 (PEALD)/SiO2 deposition using ALD2

The content on this page, including all images and pictures, was created by DTU Nanolab staff, unless otherwise stated.

Feedback to this page: click here

Unfortunately, the process is obsolete - It is not possible to deposit SiO2 in the cleanroom at the moment. The SAM24 precursor is organic and has degraded so much over time that it cannot be used any more.

Result from acceptance test

SiO2 deposition using SAM24 and O2 plasma precursors

The test was done with 150 cycles at 300 °C where the growth rate was measured to be 0.1222 nm/cycle.

| SAM24 | O2 plasma | |

|---|---|---|

| Nitrogen flow | 100 sccm | 200 sccm |

| Pulse time | 1.6 s | 10.0 s |

| Purge time | 8.0 s | 2.0 s |

-

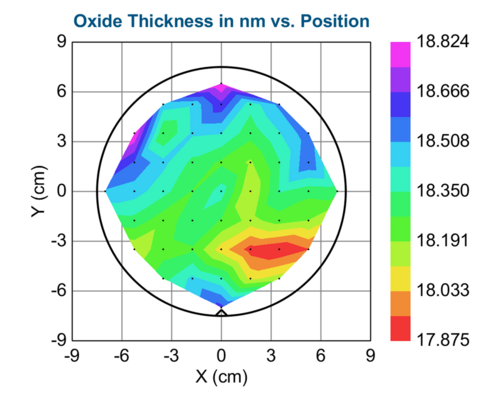

Uniformity profile across 150 mm Si wafer based on 49 measurement points measured with ellipsometer. The uniformity is shown in the figure above and the thickness values can be seen in the table below.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 18.35 | 17.88 | 18.82 | 0.20 | 5.1750 |

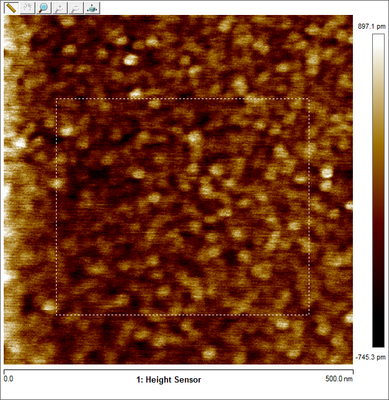

AFM measurement roughness 0.172 nm.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Nanolab (former DTU Danchip), 2016-2017.

SiO2 deposition on trenches using SAM25 and O2 plasma precursors

The test was done with 200 cycles at 300 °C where the average growth rate was measured to be 0.1629 nm/cycle. (Average thickness/number of cycles)

| SAM24 | O2 plasma | |

|---|---|---|

| Nitrogen flow | 100 sccm | 200 sccm |

| Pulse time | 1.6 s | 20.0 s |

| Purge time | 20.0 s | 10.0 s |

Additionally the picoflow was used for the SAM24 precursor.

Compared to the HfO2 covered trenches the SiO2 coated seem homogeneous.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Nanolab (former DTU Danchip), 2016-2017.