Feedback to this page: click here

The content on this page, including all images and pictures, was created by Berit Herstrøm @ DTU Nanolab (BGHE), unless otherwise stated.

InP etching with Cl2 and H2 including some Ar (Done by bghe@Nanolab)

| Parameter

|

SiO2 mask before etch

|

Carrier

|

Coil power

|

Platen power

|

Pressure

|

Flow rate Cl2

|

Flow rate H2

|

Flow rate Ar

|

T

|

Process time

|

Comment

|

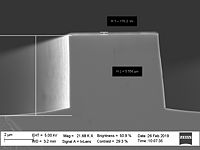

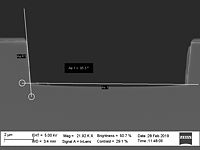

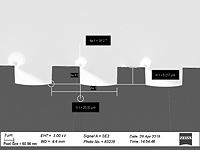

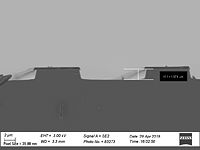

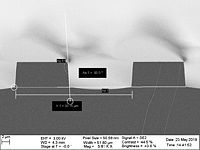

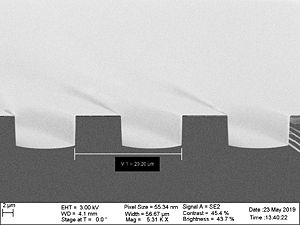

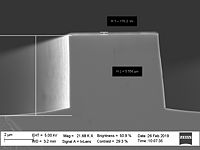

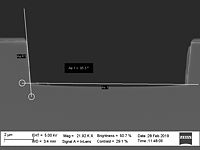

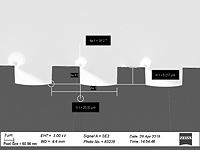

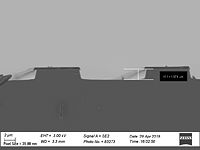

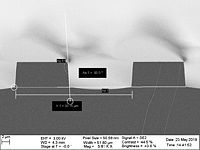

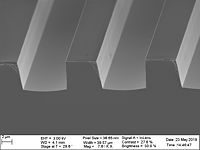

Results image1

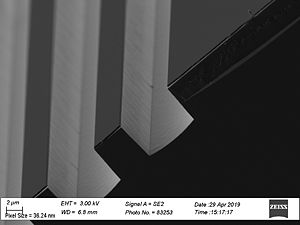

|

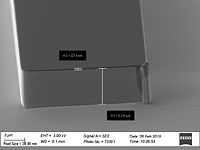

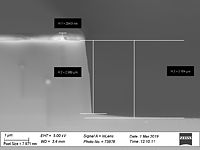

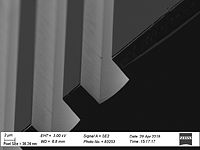

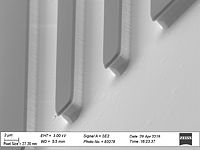

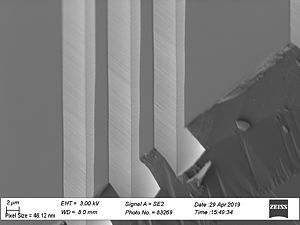

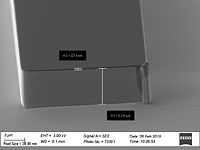

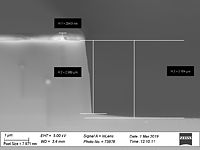

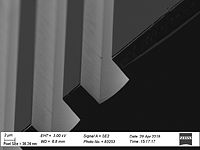

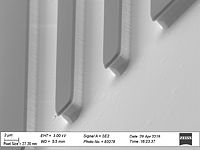

Results image2

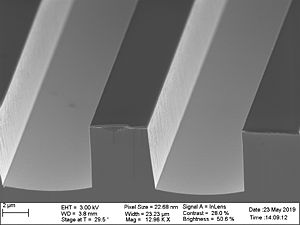

|

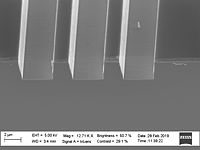

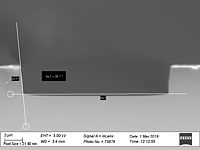

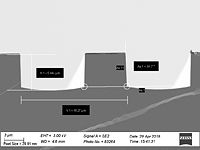

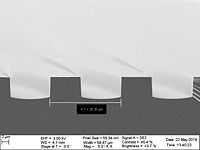

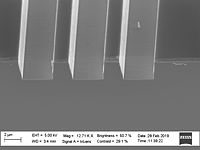

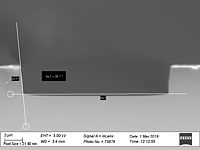

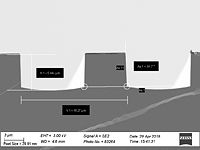

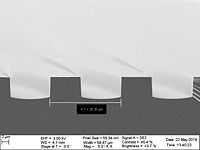

Results image3

|

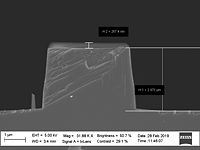

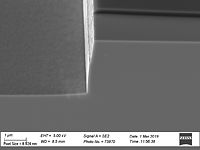

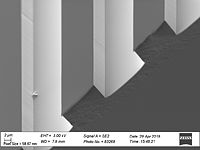

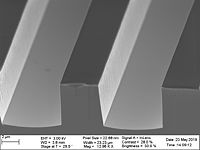

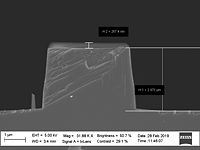

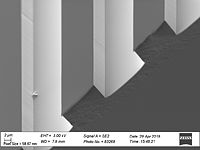

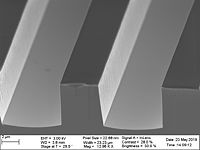

CD change

|

Profile angles

|

Etch rate in InP

|

Etch rate in SiO2

|

Selectivity (InP:SiO2)

|

| 20190222 s009209 s12

|

500nm

|

silicon

|

800W

|

150 W / 134V

|

0.5 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

|

|

|

|

90

|

925nm/min

|

54 nm/min

|

~17

|

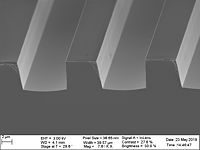

| 20190226 s009224 s13

|

500nm

|

silicon

|

800W

|

150 W /134V

|

1.0 mTorr

|

6.6 sccm

|

5.4 sccm

|

12 sccm

|

180

|

4:00 min

|

|

|

|

|

|

~95 degrees

|

750 nm/min

|

58 nm/min

|

~13

|

| 20190222 s009226 s14

|

500nm

|

silicon

|

1200 W

|

150 W /87V

|

1.0 mTorr

|

6.6 sccm

|

5.4 sccm

|

12 sccm

|

180

|

4:00 min

|

|

|

|

|

|

~95 degrees

|

790 nm/min

|

51 nm/min

|

~15.5

|

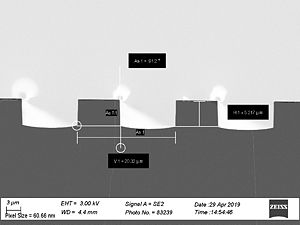

| 20190403 s s15

|

500nm

|

silicon

|

800W

|

150 W / 140V

|

0.5 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

|

|

|

|

91.2-92.1 larger on smaller lines

|

893-972 nm/min

|

52 nm/min

|

17-19

|

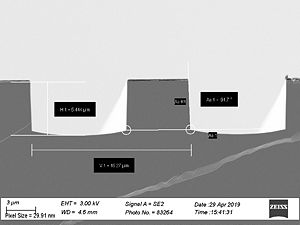

| 20190403 s s16

|

500nm

|

silicon

|

600W

|

150 W / 180V

|

0.5 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

|

|

|

|

91.2-92.1 larger on smaller lines

|

900-940 nm/min

|

53 nm/min

|

17-18

|

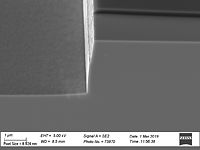

| 20190403 s s17

|

500nm

|

silicon

|

1200W

|

150 W/50W 0V

|

0.5 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

|

|

|

|

Undercut

|

330 nm/min

|

6-7 nm/min

|

50

|

| 20190501 s18

|

500nm

|

silicon

|

1200W

|

150 W 110V

|

0.6 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

|

|

|

|

91.5-92.0

|

927 nm/min

|

55 nm/min

|

17

|

| 20190501 s19

|

500nm

|

silicon

|

1200W

|

220 W 150V

|

0.6 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:00 min

|

|

Process Failed

|

|

|

|

|

nm/min

|

nm/min

|

|

| 20190501 s20

|

500nm

|

silicon

|

1200W

|

220 W /150V

|

0.6 mTorr

|

6.6 sccm

|

5.4 sccm

|

0 sccm

|

180

|

6:10 min

|

|

|

|

|

|

93-94

|

1077 nm/min

|

70 nm/min

|

15

|

|

|

500nm

|

silicon

|

800W

|

150 W /

|

1.0 mTorr

|

6.6 sccm

|

9.4 sccm

|

8.0 sccm

|

180

|

7:30 min

|

|

|

|

|

|

degrees

|

nm/min

|

nm/min

|

|

Variation of coil power only

-

s15 800W, 870 nm/min

-

s16 600W, 907 nm/min

-

s18 1200W, 927 nm/min