Specific Process Knowledge/Etch/ICP Metal Etcher/silicon/nano/Sinan331-2

Appearance

The Sinano3.31 recipe

| Recipe | Gas | BCl3 5 sccm, HBR 15 sccm |

|---|---|---|

| Pressure | 2 mTorr, Strike 3 secs @ 5 mTorr | |

| Power | 900 W CP, 75 W PP | |

| Temperature | 50 degs | |

| Hardware | 30 mm Spacers | |

| Time | 60, 120 and 180 secs | |

| Conditions | Run ID | 461, 462 and 463 |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | |

| Mask | 190 nm zep |

- The results of the Sinano3.31 recipe

-

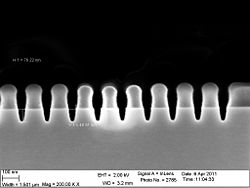

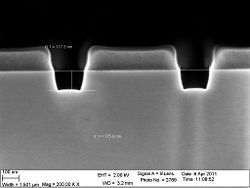

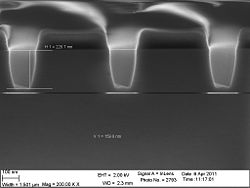

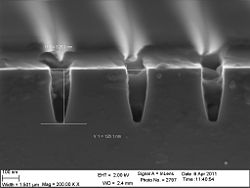

The 30 nm trenches etched 60 seconds

-

The 60 nm trenches etched 60 seconds

-

The 90 nm trenches etched 60 seconds

-

The 120 nm trenches etched 60 seconds

-

The 150 nm trenches etched 60 seconds

-

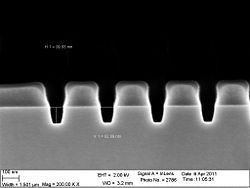

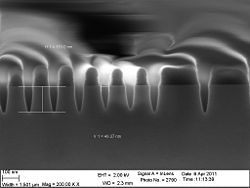

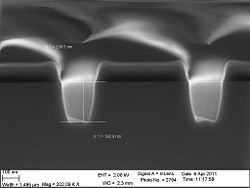

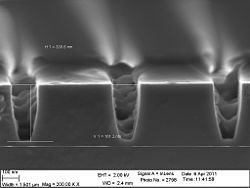

The 30 nm trenches etched 120 seconds

-

The 60 nm trenches etched 120 seconds

-

The 90 nm trenches etched 120 seconds

-

The 120 nm trenches etched 120 seconds

-

The 150 nm trenches etched 120 seconds

-

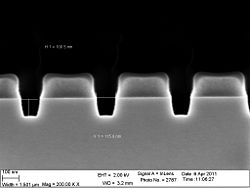

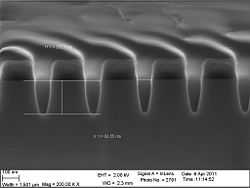

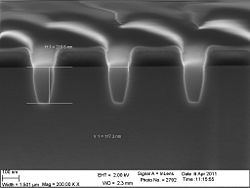

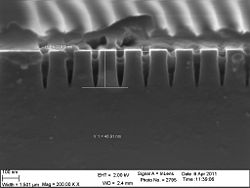

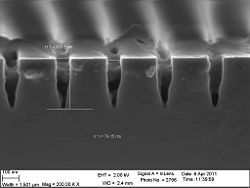

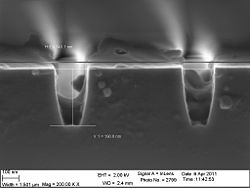

The 30 nm trenches etched 180 seconds

-

The 60 nm trenches etched 180 seconds

-

The 90 nm trenches etched 180 seconds

-

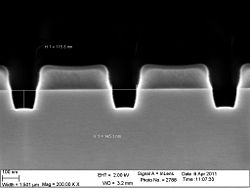

The 120 nm trenches etched 180 seconds

-

The 150 nm trenches etched 180 seconds

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rate | nm/min | 73 | 98 | 108 | 111 | 113 | 101 | 16 |

| Sidewall angle | degs | 78 | 81 | 79 | 78 | 79 | 79 | 1 |

| CD loss | nm/edge | -7 | -21 | -20 | -15 | -34 | -19 | 10 |

| CD loss foot | nm/edge | -1 | -7 | -6 | -4 | -7 | -5 | 3 |

| Bowing | 10 | 7 | 12 | 8 | 9 | 9 | 2 | |

| Bottom curvature | -34 | -4 | 2 | 6 | 5 | -5 | 17 | |

| Zep etch rate | nm/min | 47 | ||||||

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rate | nm/min | 76 | 98 | 107 | 116 | 117 | 103 | 17 |

| Sidewall angle | degs | 84 | 82 | 81 | 81 | 80 | 82 | 2 |

| CD loss | nm/edge | -4 | -16 | -15 | -13 | -24 | -15 | 7 |

| CD loss foot | nm/edge | 1 | -3 | -1 | -1 | 3 | 0 | 2 |

| Bowing | 12 | 21 | 18 | 27 | 22 | 20 | 5 | |

| Bottom curvature | -17 | -17 | -6 | 10 | 12 | -3 | 14 | |

| Zep etch rate | nm/min | 45 | ||||||

| Nominal trench line width | ' | 30 | 60 | 90 | 150 | Average | Std. dev. |

| Etch rate | nm/min | 73 | 99 | 107 | 114 | 98 | 18 |

| Sidewall angle | degs | 85 | 84 | 83 | 81 | 83 | 2 |

| CD loss | nm/edge | -6 | -15 | -12 | -25 | -14 | 8 |

| CD loss foot | nm/edge | 0 | -1 | 2 | 2 | 1 | 2 |

| Bowing | 18 | 26 | 26 | 29 | 25 | 5 | |

| Bottom curvature | -27 | -27 | -7 | 9 | -13 | 17 | |

| Zep etch rate | nm/min | 36 | |||||