Specific Process Knowledge/Etch/IBE⁄IBSD Ionfab 300/IBE Ti etch

Appearance

Feedback to this page: click here

The content on this page, including all images and pictures, was created by Berit Herstrøm @ DTU Nanolab (BGHE), unless otherwise stated.

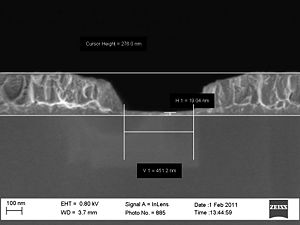

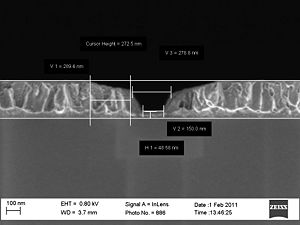

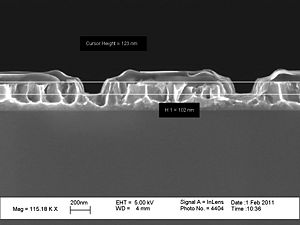

Results from the acceptance test in February 2011

Acceptance test for Ti etch :

| . | Acceptance Criteria |

Acceptance Results |

|---|---|---|

| Substrate information |

|

. |

| Material to be etched |

|

. |

| Mask information |

|

. |

| Features to be etched |

|

. |

| Etch depth |

|

|

| Etch rate |

|

|

| Etch rate uniformity |

|

|

| Reproducibility |

|

|

| Selectivity (Ti etch rate/ZEP etch rate) |

|

|

| Etch profile |

|

|

Process parameters for the acceptance test

| Parameter | Ti etch acceptance |

|---|---|

| Neutralizer current [mA] | 550 |

| RF Power [W] | 1200 |

| Beam current [mA] | 500 |

| Beam voltage [V] | 600 |

| Beam accelerator voltage | 400 |

| Ar flow to neutralizer [sccm] | 6.0 |

| Ar flow to beam [sccm] | 6.0 |

| Rotation speed [rpm] | 20 |

| Stage angle [degrees] | 20 |