Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using RIE1 or RIE2

Feedback to this page: click here

The content on this page, including all images and pictures, was created by Berit Herstrøm @ DTU Nanolab (BGHE), unless otherwise stated.

Both RIE's (RIE1 and RIE2) for silicon based etching has been decommissioned

RIE (Reactive Ion Etch) can be used for etching silicon oxide. The etch is anisotropic with vertical or angled sidewalls depending on the process recipe and the masking material and geometry. The SiO2 is etched by flour radicals assisted by ion bombardment.

The substrate:

Must be a wafer of 4" or below or small pieces, not higher than about 2 mm. The system can be set up for 6", please ask 2 weeks in advance.

The silicon can be masked by these materials:

- Photoresist

- E-beam resist

- Silicon

- Silicon Nitride

- Aluminium

- Other metals if they cover less than 5% of the wafer area.

Most used recipes:

QC results

| Quality Controle (QC) for RIE2 - oxide etch | ||||||||||||||||||||

|

Resist as masking material:

| Recipe: | 1SiO2mre |

|---|---|

| Masking material | Photoresist |

| CF4 flow | 14 sccm |

| CHF3 flow | 26 sccm |

| Pressure | 100 mTorr |

| RF-power | 60 W |

| Expected results in RIE1 (has been decommissioned) | Expected results in RIE2 | |

|---|---|---|

| Etch rate in SiO2 |

~20-30 nm/min |

~20-30 nm/min |

| Etch rate in Si3N4 | ? | ? |

| Etch rate in P-Si (when used as mask) |

~30 nm/min |

~30 nm/min |

| Etch rate in Si

(etching down to Si) |

Expected <2 nm/min |

Expected <2 nm/min |

mre:mask resist

PolySilicon as masking material

| Recipe: | 1SiO2msi |

|---|---|

| Masking material | Silicon |

| CF4 flow | 8 sccm |

| CHF3 flow | 40 sccm |

| Pressure | 150 mTorr |

| RF-power | 150 W |

| Expected results in RIE1 (HAS BEEN DECOMMISSIONED) | Expected results in RIE2 | |

|---|---|---|

| Etch rate in SiO2 |

~70-80 nm/min |

~70-80 nm/min |

| Etch rate in Si3N4 | ? | ? |

| Etch rate in P-Si (when used as mask) |

~20-30 nm/min |

~20-30 nm/min |

| Etch rate in Si

(etching down to Si) |

? | ? |

| Images | Etches with p-Si as masking material |

msi:mask silicon

The recipe: 1SiO2bre (se below) can also be used with p-Si as masking material.

Burned resist as masking material (developed for waveguides by Haiyan Ou @DTU Photonics):

| Recipe: | 1SiO2mbr |

|---|---|

| Masking material | Burned resist (250oC 1h) |

| CHF3 flow | 84 sccm |

| Pressure | 60 mTorr |

| RF-power | 200 W |

| Expected results in RIE1 (HAS BEEN DECOMMISSIONED) | Expected results in RIE2 | |

|---|---|---|

| Etch rate in SiO2 |

~120 nm/min |

~120 nm/min |

| Etch rate burned resist |

? |

? |

| Etch rate in Si3N4 |

? |

? |

| Etch rate in P-Si (when used as mask) |

? nm/min |

? nm/min |

| Etch rate in Si

(etching down to Si) |

? |

? |

| Images |

Etches with p-Si as masking material Etches with burned resist as masking material |

Etches with burned resist as masking material |

mbr:mask burned resist

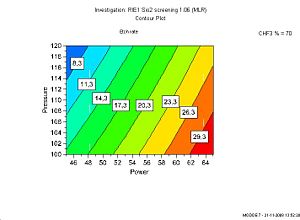

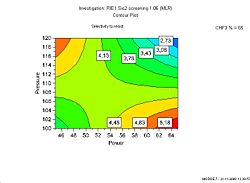

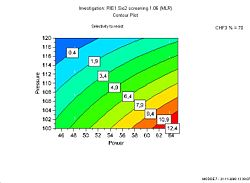

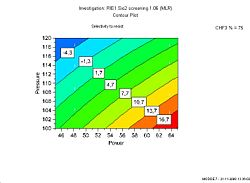

A survey of the parameter space using photoresist as masking material

A DOE has been performed. A short summery is given here: (in progress)

RIE1: RIE1 has been decommissioned but the results are probably similar on RIE2

A Design Of Experiment (DOE) has been performed. A screening experiment: full factorial with to levels: 9 different runs and 3 repetitions. Results from a screening experiment should be taken "with a gain of salt" meaning use it only as a rough guide line and test your recipe before use.

Selectivity to photoresist

|

|---|

Etch profile angle <br\> The etch profile was also examined but there was not found any significant correlation between the profile angle and the process parameters.