Specific Process Knowledge/Etch/DRIE-Pegasus/nanoetch/nano142-pxnano2

Appearance

Feedback to this page: click here

Unless otherwise stated, the content of this page was created by the dry etch group at DTU Nanolab

nano1.42 versus pxnano2

| Recipe | nano1.42 | pxnano2 | ||

|---|---|---|---|---|

| Tool | Pegasus | ASE | ||

| Parameters | Gas | C4F8 75 sccm, SF6 38 sccm | D: C4F8 50 sccm | E: C4F8 50 sccm, SF6 50 sccm |

| Power | 800 W CP, 40 W PP | D: 500 W CP | E: 350 W CP, 30 W PP | |

| Pressure | 4 mTorr, Strike 3 secs @ 15 mTorr | 10 mTorr | ||

| Temperature | -20 degs | 20 degrees | ||

| Hardware | 100 mm Spacers | ? | ||

| Time | 120 secs | D: 3 secs, E: 5 secs, total 12 cycles or 96 secs | ||

| Conditions | Run ID | 2150 | wf_2e09b_mar23 | |

| Conditioning | Sequence: Oxygen clean, MU tests, processes, no oxygen between runs | none | ||

| Mask | 211 nm zep etched down to 80 nm | 211 nm zep etched down to 130 nm | ||

- The results

-

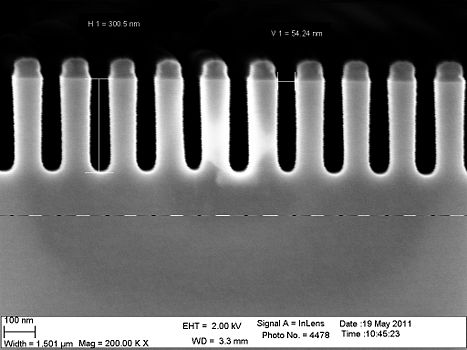

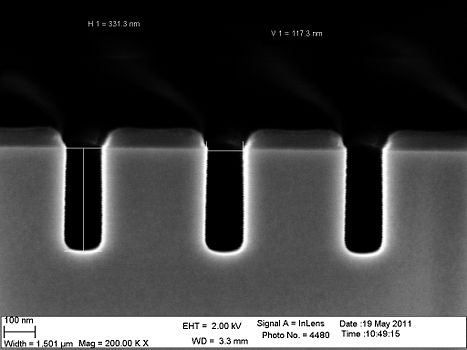

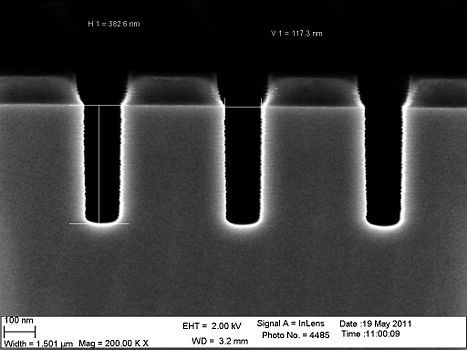

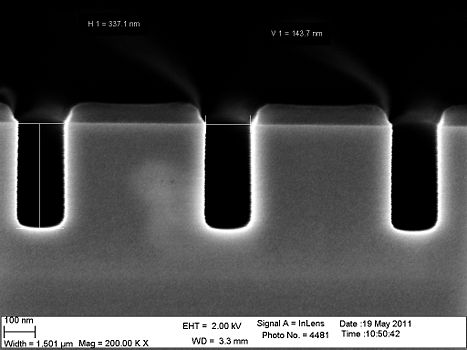

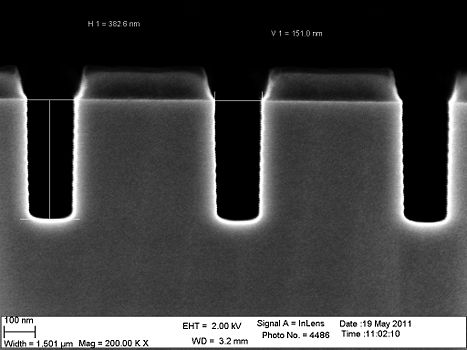

nano1.42: The 30 nm trenches etched 120 seconds

-

pxnano2: The 30 nm trenches etched 96 seconds

-

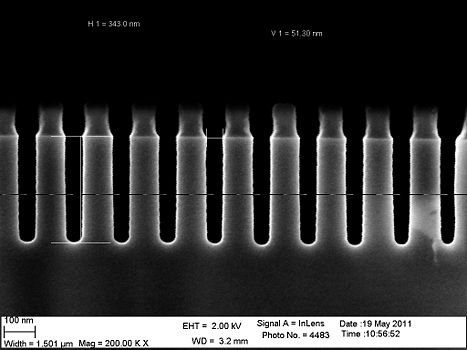

nano1.42: The 60 nm trenches etched 120 seconds

-

pxnano2: The 60 nm trenches etched 96 seconds

-

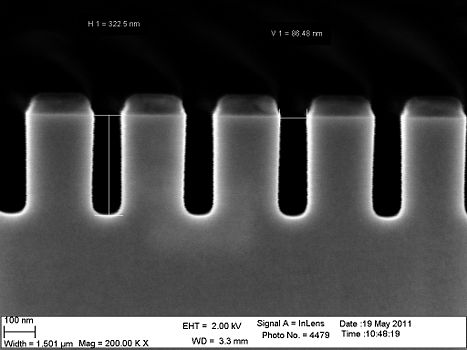

nano1.42: The 90 nm trenches etched 120 seconds

-

pxnano2: The 90 nm trenches etched 96 seconds

-

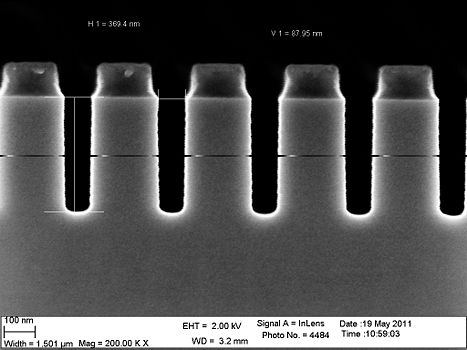

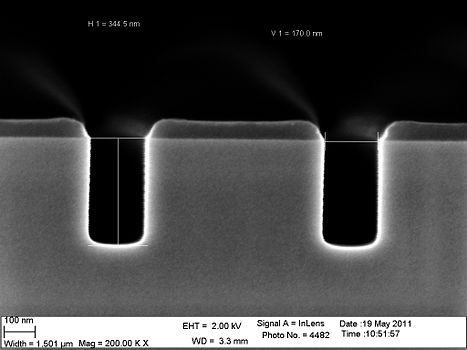

nano1.42: The 120 nm trenches etched 120 seconds

-

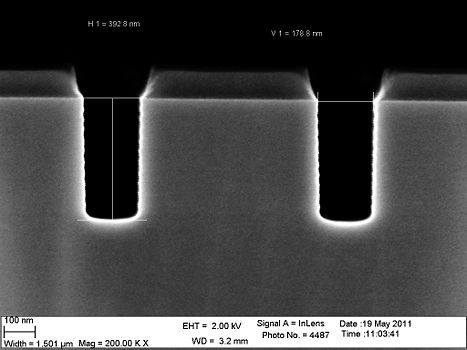

pxnano2: The 120 nm trenches etched 96 seconds

-

nano1.42: The 150 nm trenches etched 120 seconds

-

pxnano2: The 150 nm trenches etched 96 seconds

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rates | nm/min | 149 | 161 | 166 | 169 | 170 | 163 | 9 |

| Sidewall angle | degs | 91 | 91 | 90 | 90 | 90 | 90 | 0 |

| CD loss | nm/edge | 3 | -11 | -12 | -34 | -36 | -18 | 17 |

| CD loss foot | nm/edge | 9 | 1 | 1 | -20 | -9 | -4 | 11 |

| Bowing | 4 | 4 | 2 | 6 | 2 | 4 | 2 | |

| Bottom curvature | -46 | -40 | -37 | -31 | -23 | -35 | 9 | |

| zep | nm/min | 66 |

| Nominal trench line width | ' | 30 | 60 | 90 | 120 | 150 | Average | Std. dev. |

| Etch rates | nm/min | 215 | 232 | 240 | 243 | 244 | 235 | 12 |

| Sidewall angle | degs | 90 | 89 | 89 | 89 | 89 | 89 | 0 |

| CD loss | nm/edge | 1 | -10 | -11 | -33 | -33 | -17 | 15 |

| CD loss foot | nm/edge | 6 | 2 | 1 | -19 | -6 | -3 | 10 |

| Bowing | 4 | 2 | 4 | 3 | 1 | 3 | 1 | |

| Bottom curvature | -36 | -29 | -22 | -19 | -17 | -25 | 8 | |

| zep | nm/min | 51 | ||||||