| Equipment

|

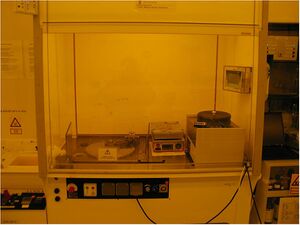

SSE Spinner

|

KS Spinner

|

| Purpose

|

|

- Spinning and baking of AZ2514E resist

- Spinning and baking of AZ4562 resist

- Spinning and baking of e-beam resist

|

- Spinning and baking of AZ2514E resist

- Spinning and baking of AZ4562 resist

- Spinning and baking of SU8 resist

|

| Performance

|

Substrate handling

|

- Cassette-to-cassette

- Edge handling chuck

|

- Single substrate

- Non-vacuum chuck for fragile substrates

|

| Permanent media

|

- AZ5214E resist

- AZ4562 resist

- Acetone for chuck cleaning

- Acetone for drip pan

|

- AZ5214E resist

- PGMEA for edge bead removal

- Acetone for chuck cleaning

|

| Manual dispense option

|

|

- yes

- pneumatic dispense for SU8 resist

|

| Process parameter range

|

Parameter 1

|

|

|

| Parameter 2

|

|

|

| Substrates

|

Batch size

|

- 24 50 mm wafers

- 24 100 mm wafers

- 24 150 mm wafers

|

- 1 100 mm wafers

- 1 150 mm wafers

|

| Allowed materials

|

- Allowed material 1

- Allowed material 2

|

- Allowed material 1

- Allowed material 2

- Allowed material 3

|