Specific Process Knowledge/Lithography/EBeamLithography/BEAMER

Feedback to this page: click here

THIS PAGE IS UNDER CONSTRUCTION

Beamer guide

All users of the JEOL 9500 system must have their pattern converted to the JEOL52 V3.0 (V30) format, this conversion is done using Beamer. Beamer can however do many other operations than this simple format conversion. In this section we will describe some of the most frequently used nodes and also provide a few node setups for specialized tasks.

Node descriptions

The main nodes of Beamer and their primary use are listed in the table below. Further details of each node are also provided below.

| Module/method | Short description |

|---|---|

| Import | Layout import |

| Export | Export to V30 and JDI |

| Edit | Opens the pattern in LayoutEditor |

| Heal | Used to remove pattern overlaps |

| Transform | Used to rotate, scale or shift patterns |

| Bias | Used to grow or shrink patterns |

| AND, OR, MINUS, XOR, P-XOR, NOT | Applies a boolean operation to two inputs |

| Extract | Used to extract layers or regions of a design |

| Replace | Used to replace a cell in the design with a cell from another design |

| Merge | Merges multiple patterns into one |

| Grid | Can be used to increase layout grid and reduce geometry vertice count |

| Mapping | Used to rename layers |

| Filter | Used to select geometry based on rules, for instance by dimensions |

| Fracture | Gives the user much more control over pattern fracturing than the default export fracturing |

| ChipPlace | Graphical interface to set up arrays of patterns and assign dose to each element, excellent for dose testing |

| Visual-Job | Graphical user interface that can be used to entirely setup a job and have Beamer write the SDF and JDF files |

| PEC | Used to apply Proximity Effect Correction to a pattern by dose modulation |

| Shape-PEC | Applies PEC by both dose modulation and shape modulation, i.e. by moving pattern edges |

| 3D-PEC | Can be used for PEC of thick resist layers for gray scale lithography or PEC on multi-resist layer structures |

| Corner-PEC | PEC with emphasis on creating sharp corners |

| FDA | Feature Dose Assignment, allows assignment of doses to pattern elements, regions or entire layers |

| Rule-OPC | Used for rule based process control, for instance offset edges based on pattern dimensions |

| 2D Simulation | Used to simulate energy distribution (dose) in the resist and resulting dimensions |

| Metrology | Can be used to measure pattern dimensions, for instance to generate table of dimensions after Shape-PEC |

Import node

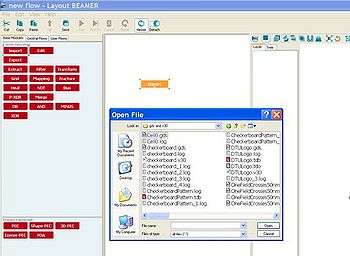

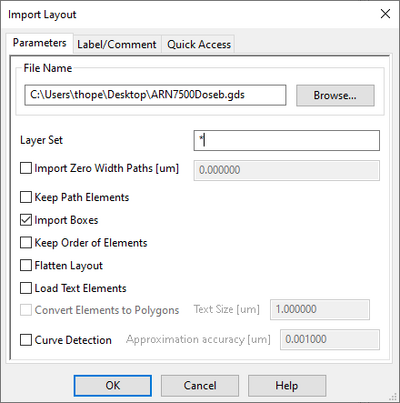

The import node is used to import geometry into Beamer. While we recommend GDS for import Beamer supports the following formats: GDSII, DXF, OASIS, CIF, TXL, LEDB, PNG, STL, JEOL51, JEOL52, Raith (VB6, FRE, GPF, IWFL), NuFlare, MEBES, Micronic, NPI, HIMT and ADVANTEST. The options available are:

Import Zero Width Paths: Allows polygonal paths to be imported with a width.

|

|

Import node options. Illustration: Thomas Pedersen. |

Node setups

Proximity Effect Correction

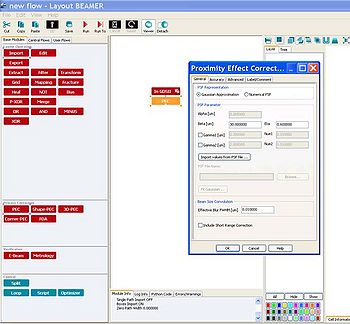

Apart from conversion to V30 the prime use of Beamer is to do Proximity Effect Correction (PEC). This is done through the PEC node. The PEC node has a quite a few options and different ways to define a Point Spread Function (PSF). The PSF is a radially symmetric function around the beam spot that defines dose received by the resist both due to the incident beam but also from scattered electrons. The PSF used in Beamer can be defined in two ways; either based on gaussian functions where the user supplies the parameters used to define the functions, or the PSF can be based on Monte Carlo simulations of electron scattering. In any case the PSF is mainly dependent on beam energy (acceleration voltage) and substrate material. The JEOL 9500 system is always used at 100 kV, the Raith eLine system can however be used at any acceleration voltage between 1 and 30 kV. The PSF changes drastically with acceleration voltage and it is very important to use a PSF generated at the correct acceleration voltage. Beamer comes with its own Monte Carlo simulator called Tracer. In Tracer one can set up a substrate material stack and simulate electron scattering at the desired acceleration voltage. The PSF can be output as a file and loaded into Beamer for PEC.

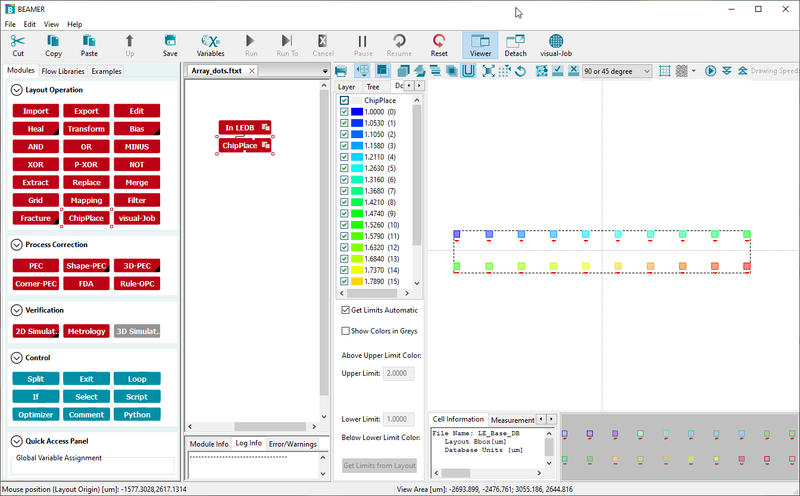

ChipPlace - easy dose test setup

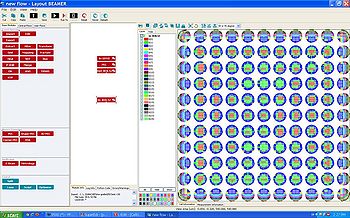

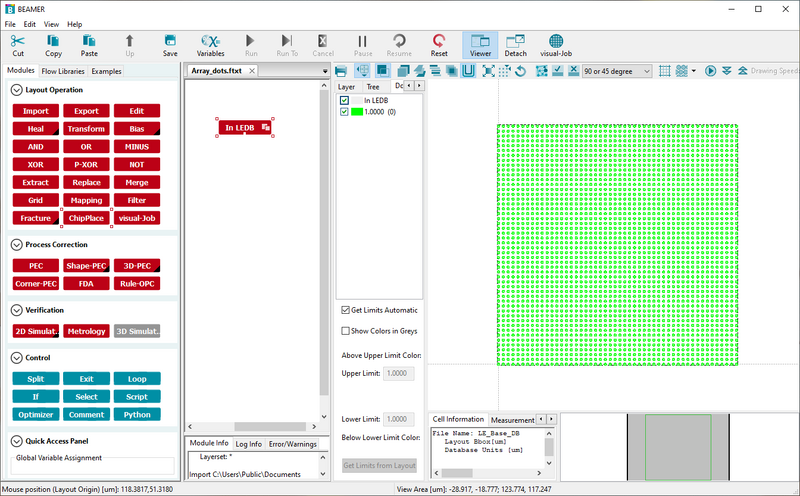

A pattern can easily be set up for a dose test using the ChipPlace module. In ChipPlace one can set up a pattern to be instanced a number of time and easily assign each instance a dose. The dose can be manually set or be linearly interpolated between a start and end value for the instanced array. The output of ChipPlace is a single pattern file with all array elements assigned to individual doses (shot ranks). This also works with patterns that already have PEC applied. In that case ChipPlace will create a combined modulation of the PEC modulation and the dose test modulation. In the example below we demonstrate how to set up dose test without PEC. If PEC is needed a PEC node can simply be added before the ChipPlace node. In the example we will use the Array_dots pattern found in the examples pane. It is a simple array of dots in a 100 x 100 µm2 box. The procedure is

- Import a design

- Add the ChipPlace node

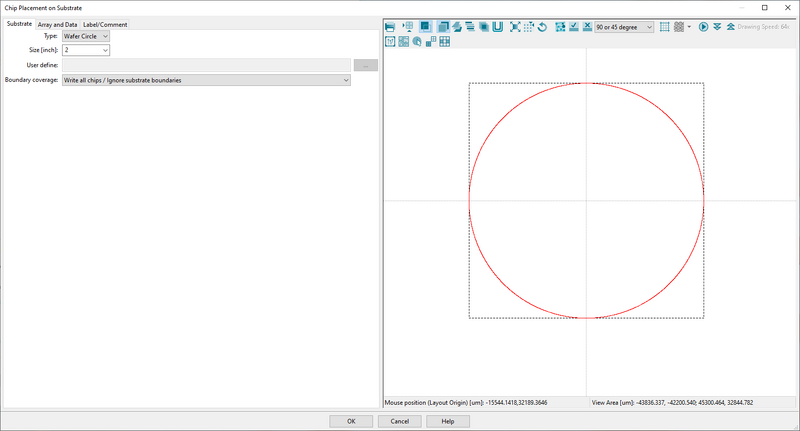

- In the Substrate tab define the substrate size. This is purely for visualization of how the pattern fits on the substrate

|

|

This example uses the Array_dots pattern supplied with Beamer. Image: Thomas Pedersen. |

|

|

Choose a substrate size to visualize placement within the substrate in ChipPlace. Image: Thomas Pedersen. |

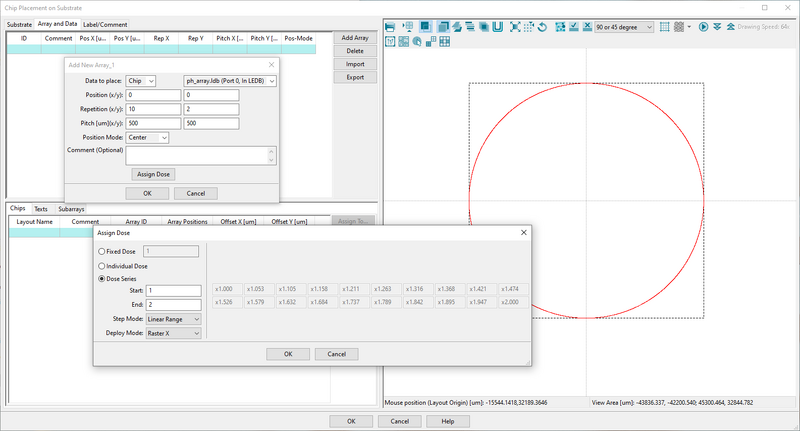

- Go to the Array and Data tab

- Click Add Array

- In Data to place choose Chip. It will then take the pattern connected to the ChipPlace module

- Fill in array data in Repitition and Pitch to create as many dose test instance as you want. In this case we create a 10 x 2 array

- Choose Center in Position Mode to have everything centered in the final output pattern (V30 file)

- Click Assign Dose to open up the dose assignment page

- Choose Dose Series and enter a start and end value. This is relative dose, i.e. a multiplier on the base dose defined by RESIST in the SDF file

- Choose Raster X in Deploy Mode to increase dose from left to right for all rows

- Click OK in both open windows to see the result

This will produce a 10 x 2 array of the pattern with a relative dose from 1 to 2. Remember this dose factor is acting as a multiplier onto the base dose defined by RESIST in the SDF file. Thus if a base dose of 200 is defined by RESIST this setup will start at 200 µC/cm2 and end at 400 µC/cm2.

| |

|

The array and dose assignment can be set up with just a few inputs. Image: Thomas Pedersen. | |

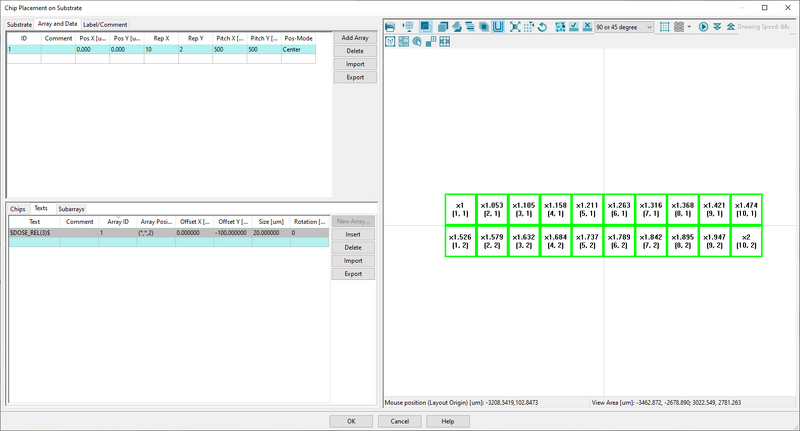

| |

|

Indicated for each element in the viewport is relative dose X and array number (x,y). Image: Thomas Pedersen. | |

To make analysis of the post exposure result easier let us add a dose label to each array element. This dose label will be exposed along with the pattern and thus when inspecting the result in SEM the (relative) dose will be visible next to the pattern. It is very easy to add:

- Go to the Texts pane in the bottom window

- Enter $DOSE_REL(3)$ to have the relative dose printed with 3 decimals accuracy

- Choose array 1 in Array ID to assign the text label to that array

- Assign text labels to all array elements with the (*,*,2) command. The "2" sets the relative dose of the labels to 2

- Assign an y-axis offset of for instance -100 µm to avoid having the label printed on top of the pattern itself

- Assign a decent size in the Size window, 20 µm will work for most cases

- Click OK in the bottom of the window to return to the Beamer view

- Run the ChipPlace node to see the result

- Add an Export node and export the result as normal

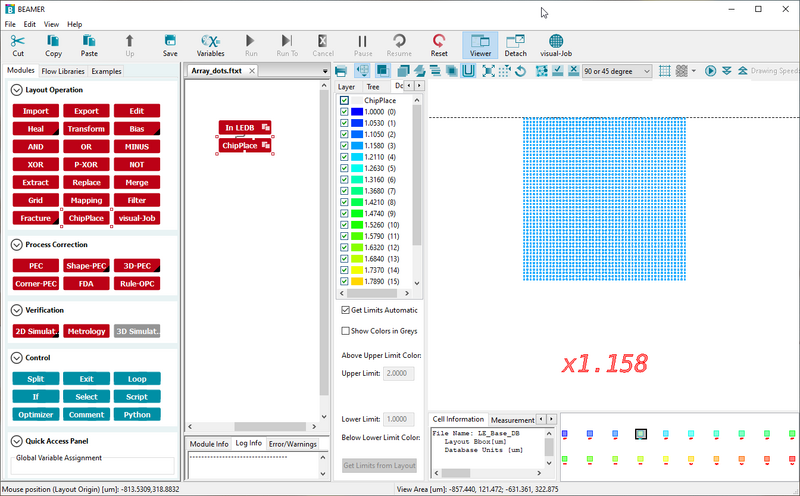

|

|

Final result of the ChipPlace node with relative doses from 1 to 2, ready for export to V30. Image: Thomas Pedersen. |

|

|

Example of the added dose labels. Image: Thomas Pedersen. |

Boolean operations

Heal

Extract

Fracture

Export

Transform

Bias

Merge

Visual-Job

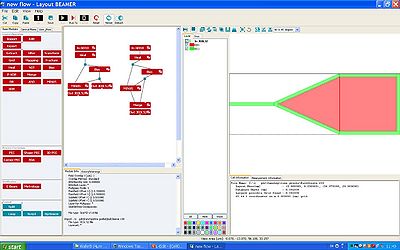

2D Simulation

Beamer

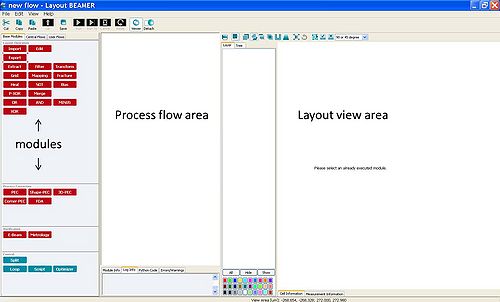

The following is a short walkthrough of the most frequently used features of Beamer. For a more in depth look at Beamer please refer to GenISys own learning material found here.

The BEAMER software is used to convert files from GDSII format to v30-format. The BEAMER software is manufactured by GenISys (www.genisys-gmbh.de) and the software is installed on the ebprep computer.

The main functions of BEAMER are:

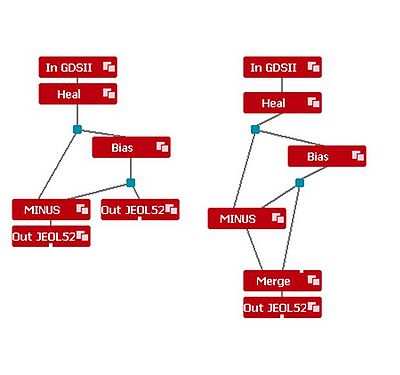

Module Function Import Imports a GDS, CIF or v30-file Export Exports to GDS, CIF or v30-format Grid Modifies the base unit of the imported file Fracture Optimizes the fracturing of the layout Heal Removes overlaps in the layout and joins abutting polygons Bias Adds or subtracts geometrical bias to the pattern Merge Merges two layouts Minus Subtracts two layouts PEC Proximity Error Correction Split Splits the output in two

To use the modules, they are dragged to the process flow area.

The inputs and outputs of each module are illustrated by white tags. Two modules are coupled to each other by positioning the input of e.g. the Export module on top of the output of the Import module. The input/output tags turns black when they are connected.

By clicking on active modules, the layout of the file becomes visible in the layout view area.

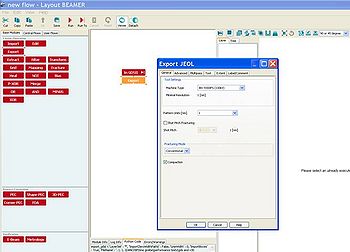

Simple conversion from GDSII to v30

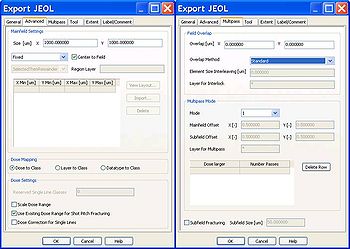

If your pattern is larger than one field size, it will be stitched by several fields. In the tab 'Multipass', you can choose to smooth the stitching errors by overlapping the fields to be stitched or by multipass method.

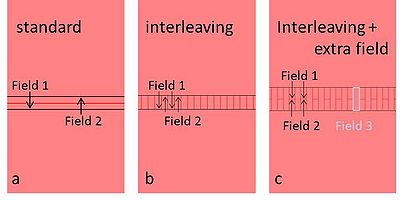

There are 3 types of overlap methods; for all 3 methods you define an overlap width:

a) standard: the overlap will be exposed with half dose both of field 1 and field2;

b) interleaving: the overlap will be finger-jointed by field 1 and field 2;

c) interleaving with extra field: the overlap will be finger-jointed by field 1, field 2 and an extra field 3, as illustrated to the right.

The multipass method smooths the field stitching errors by writing the pattern with half dose in different areas of the main deflector; by this method, pattern located in the corner of a writing field will be written partly by the corner of a writing field and partly by the central part of the writing field.

Dose variations

Dose variation defined by datatype or layertype

When designing your pattern, you can define a dose variation either by defining different areas in different GDS datatype or in different layertype.

In both cases you import the GDS-file as usual into BEAMER, importing all layers. The layers should be visible when you view the GDSfile:

If you defined different doses by different GDS layers, you should tick 'Datatype to Class' under 'Advanced' when you convert to v30.

If you defined different doses by different layer type, you should tick 'Layer to Class' under 'Advanced' when you convert to v30.

View the v30-file and make sure all variations have been converted correctly.

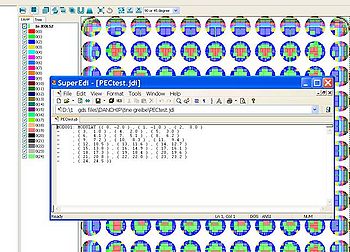

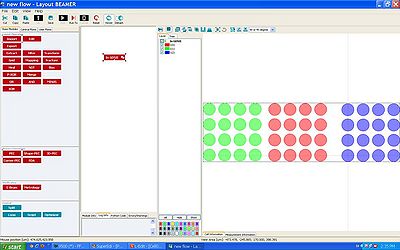

In the jdf-file, manually create a shot modulation (similar to the jdi-file created by PEC) that fits to the number of layers in your v30-file. This shot modulation should be defined in the end of the jdf-file (see the sdf- and jdf-file manual). In the example below, the three layers (green, blue and red in the BEAMER viewer to the right) are defined to have shot modulation from -20 % to + 20 % of the base-dose:

JOB/W 'TEST',4 ; 4 inch wafer

PATH DTU5M

ARRAY (0,1,0)/(10000,3,10000)

ASSIGN P(1)-> ((*,*),SHOT1)

AEND

PEND

LAYER 1

P(1) 'fredrikpnov1507prox.v30'

SPPRM 4.0,,,,1.0,1

STDCUR 0.22 ;nA

SHOT1: MODULAT (( 0, -20) , ( 1, 0) , ( 2, 20))

END

Dose variation defined by an array in jdf file

Another even faster way to define dose modulation (if you have less than 10-15 different doses) is to repeat the pattern (v30-file) in an array with different doses in the jdf file, just type the dose modulation you wish to apply to every chip in the array:

JOB/W 'TEST',4 ; 4 inch wafer

PATH DTU5M

ARRAY (-10000,2,10000)/(10000,1,10000)

ASSIGN P(1)-> ((1,1),SHOT1)

ASSIGN P(1)-> ((1,2),SHOT2)

ASSIGN P(1)-> ((2,1),SHOT3)

ASSIGN P(1)-> ((2,2),SHOT4)

AEND

PEND

LAYER 1

P(1) 'tjulahej.v30'

SPPRM 4.0,,,,1.0,1

STDCUR 0.22 ;nA

SHOT1: MODULAT (( 0, -20))

SHOT2: MODULAT (( 0, -10))

SHOT3: MODULAT (( 0, 0))

SHOT4: MODULAT (( 0, 10))

END

Proximity Error Correction (PEC)

BEAMER has a built-in proximity error correction simulation program; import the GDS-file as usual and connect the 'PEC' module to its output. In the 'Proximity Error Correction' window you can either type Beta and Eta manually or import a point spread function (PSF).

Bulk and sleeve

If you have structures with both bulky and fine parts that you wish to pattern either with different doses or different currents, you can use BEAMER to divide the structures in different layers or different v30-files.